Setup/Startup

12 3A3426EOperation

Setup/Startup

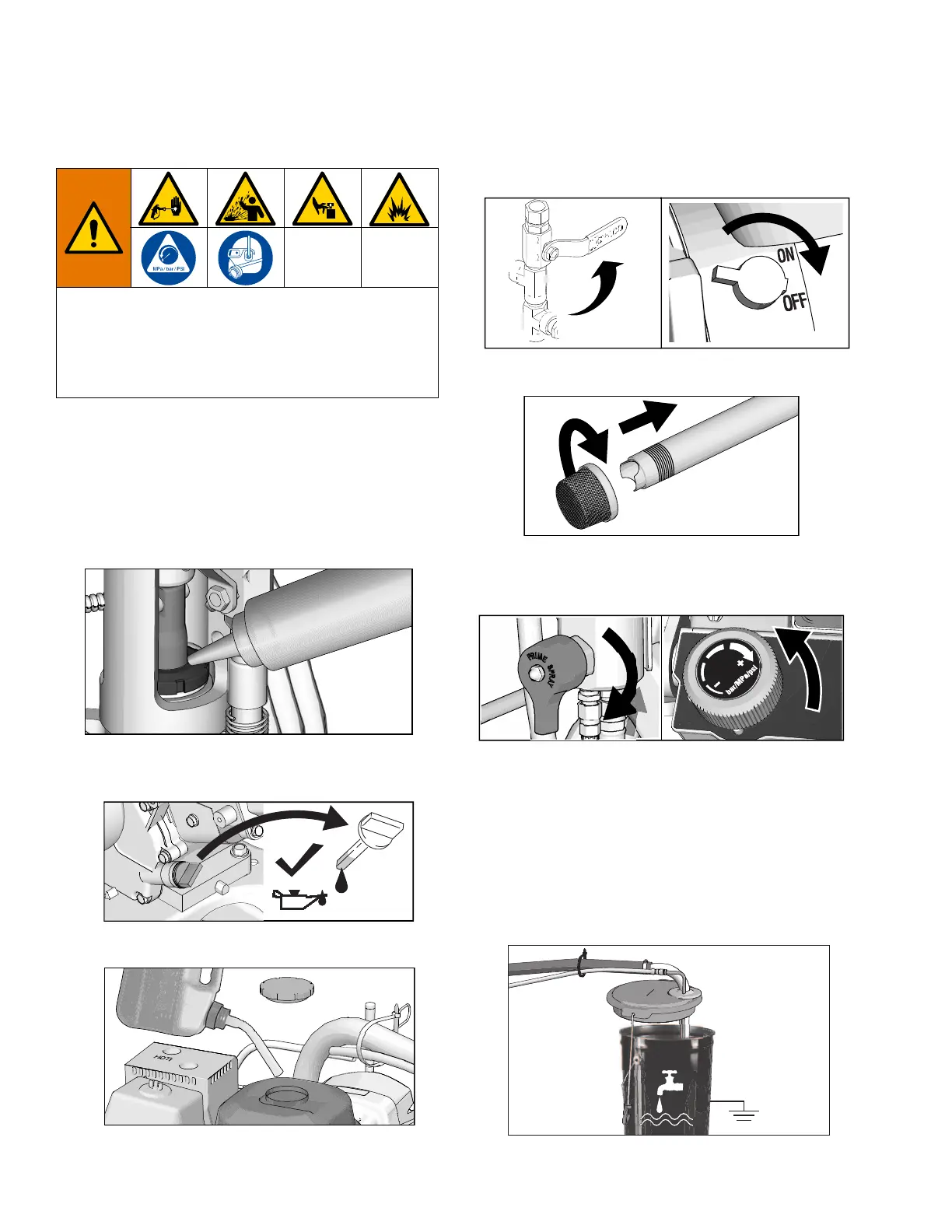

1. Perform

Pressure Relief Procedure

, page 11.

2. Perform Grounding Procedure (For Flammable

Flushing Fluids Only), page 11, if using flammable

materials.

3. Fill throat packing nut with Throat Seal Liquid (TSL)

to decrease packing wear. Both for 200

DC.

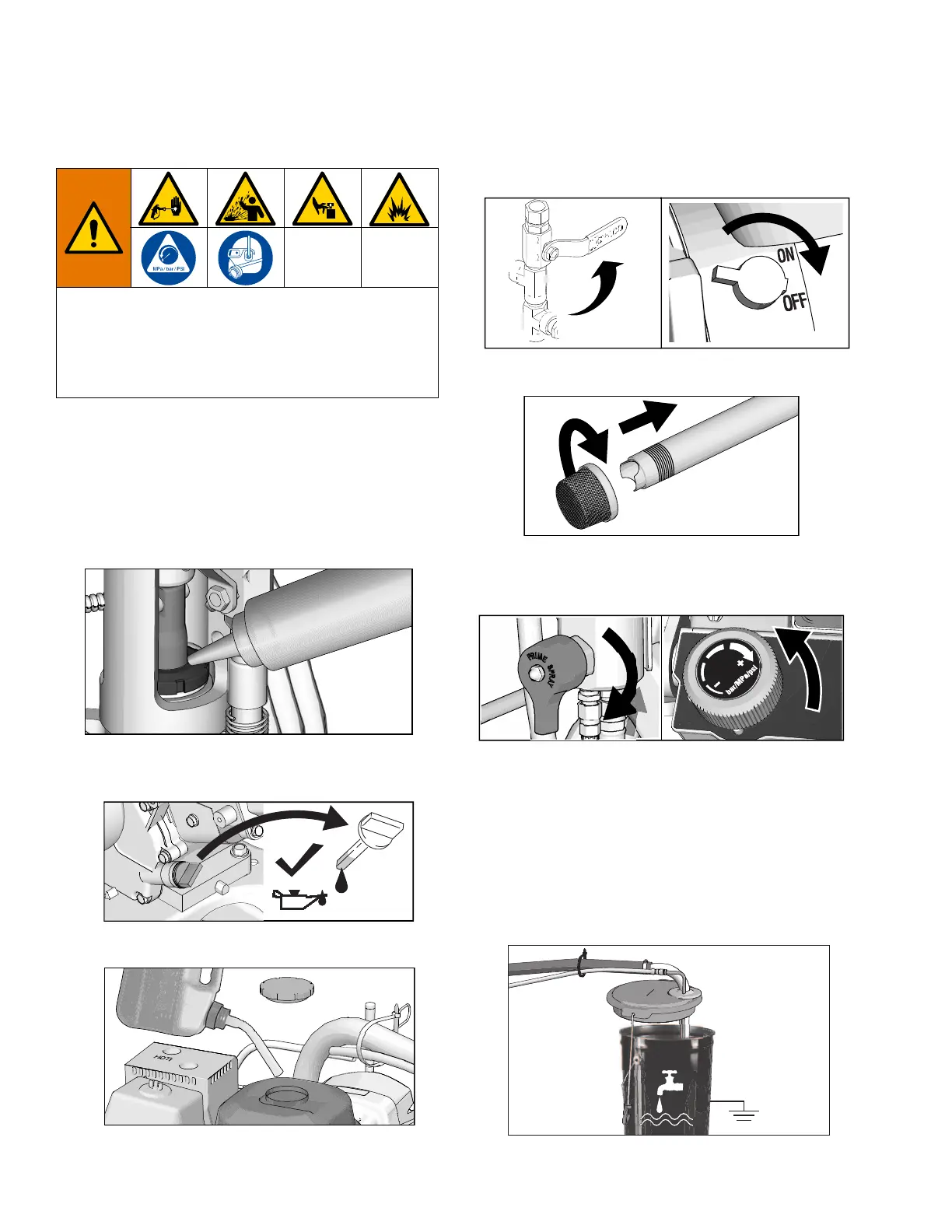

4. Check engine oil level. Add SAE 10W-30 (summer)

or 5W-30 (winter). See engine manual.

5. Fill fuel tank.

6. Set pump switch to OFF. Both for 200

DC

7. If removed, install strainer. Both for 200DC

8. Turn prime valve down (both for 200DC). Turn

pressure control counterclockwise to lowest

pressure.

NOTE: Minimum hose size allowable for proper sprayer

operation is one 3/8 in. x 22 ft for LL200

HS, or two 3/8 in. x

11’ 10” for LL200

DC.

9. Place siphon tube set in grounded metal pail

partially filled with flushing fluid. Attach ground wire

to true earth ground. Use water to flush water-base

paint and mineral spirits to flush oil-base paint and

storage oil. For 200

DC, perform this step for first

color/pump to be primed.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing fluid

and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

ti28014a

ti27504a

ti27613a

Loading...

Loading...