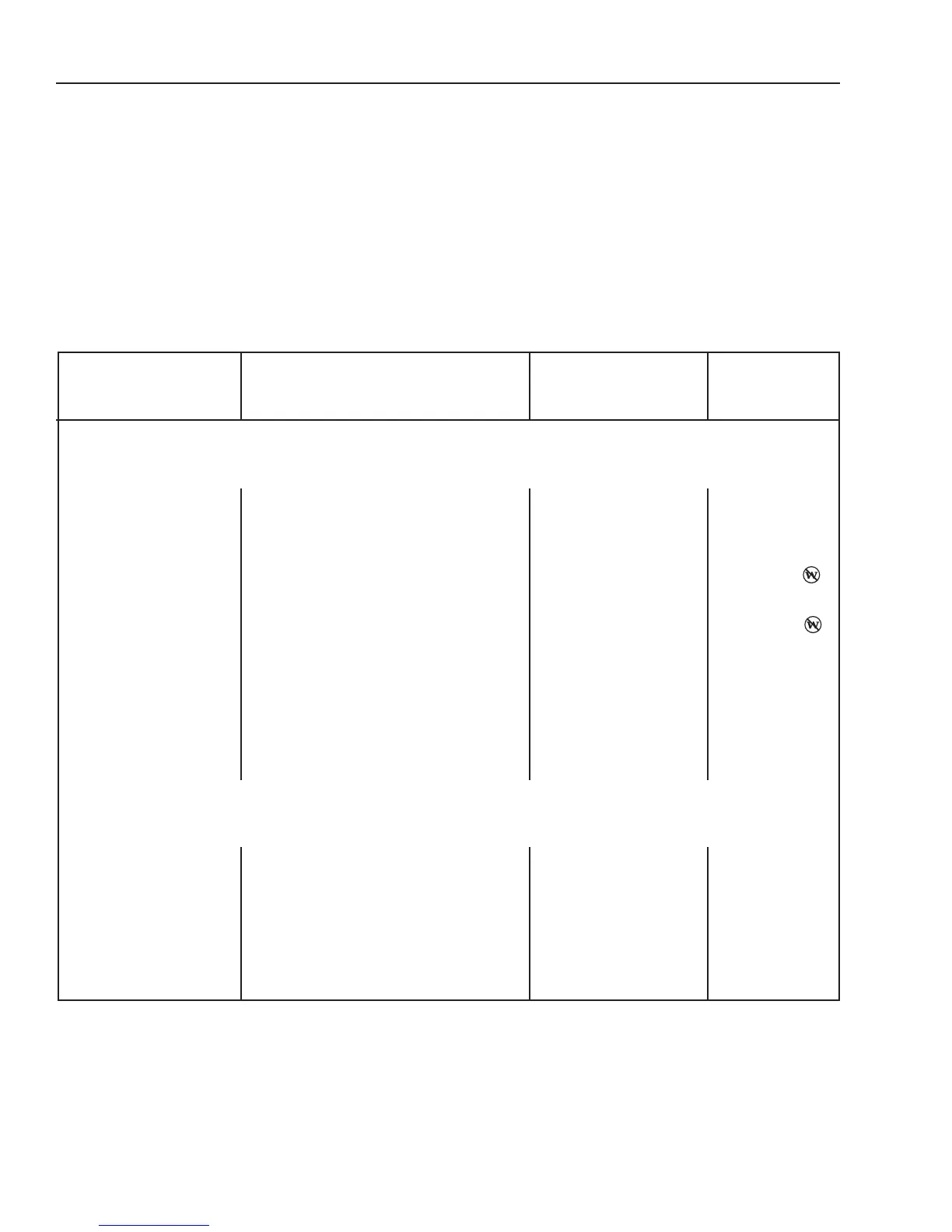

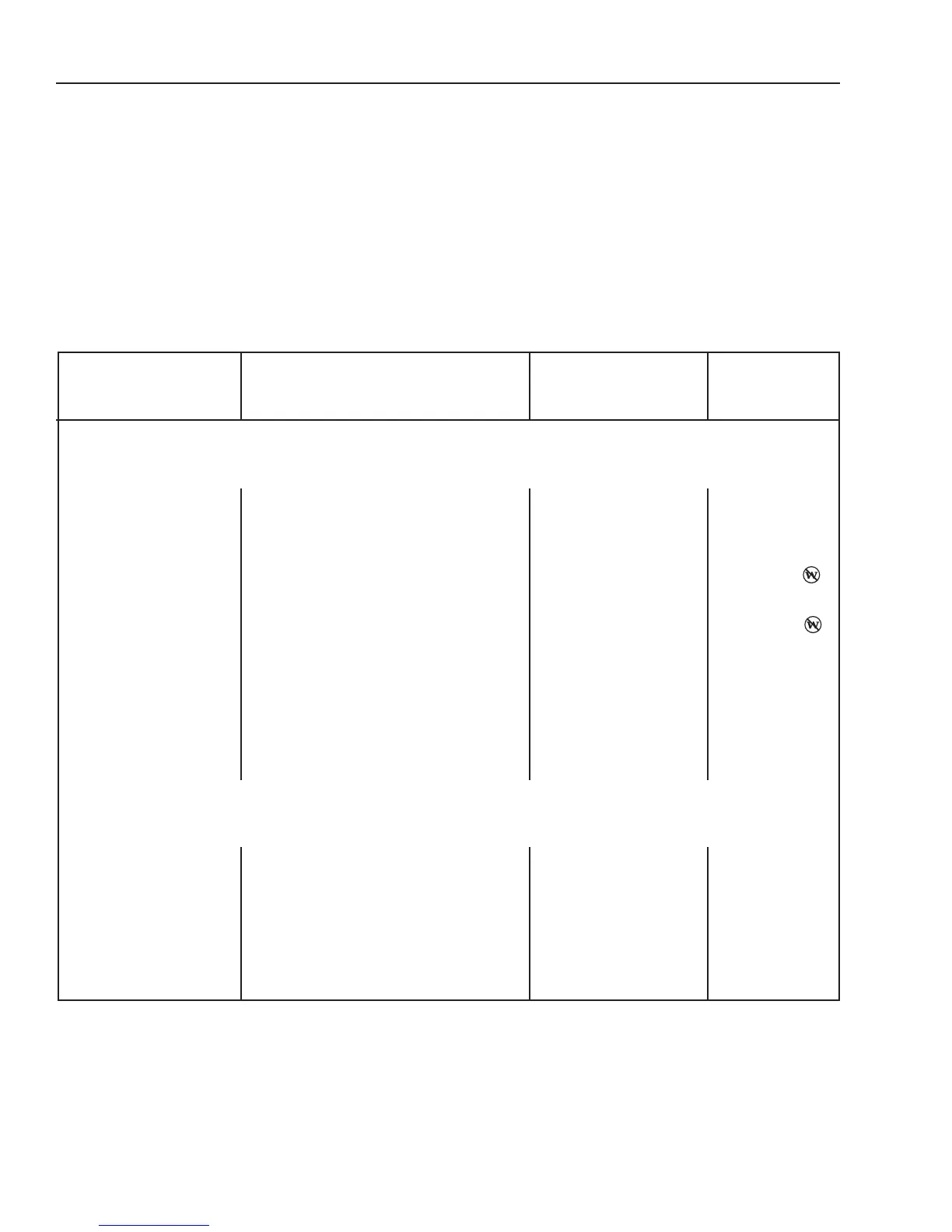

SERVICE CODES

6-8

Service Code 1

Table 1 provides information for troubleshooting when on a service call. The

c

olumns list probable causes, replacement parts and special tools needed, and a

page reference to service instructions. Proceed through the Probable Causes in

the sequence shown in the table. If the corresponding Corrective Action does not

correct the problem, proceed to the next Probable Cause and so forth, until the

problem is corrected.

Table 1 - Troubleshooting Service Code 1

Service

Reference

Location

Broken lead or Continuity check harness. Replace Digital ohmmeter ————

connector in water harness if an open circuit is detected.

probe harness.

Contaminated Clean both water probes using fine ———————— ————

water level probes. enemy cloth.

Clean probe holders. Clean holder air ———————— Page 8-12

vents for CC10-E unit.

Delime boiler ———————— Page 8-62,

8-63, or 8-64

Defective water

Replace both water level probes. ———————— Page 8-12

level probes.

Relay board and/or Perform relay board power supply Voltmeter Page 8-3

control panel operation. check.

Faulty relay board.

Replace relay board or flex cable. ———————— Page 8-22

Faulty control panel. Replace control panel. ———————— Page 8-21

WARNING

Be sure oven is disconnected from branch circuit power before performing any repair work.

WARNING

When oven power is turned on, there is high voltage present in the electrical components compartment.

(Revised 1/02)

Probable Cause

Corrective Action

Test Equipment

Loading...

Loading...