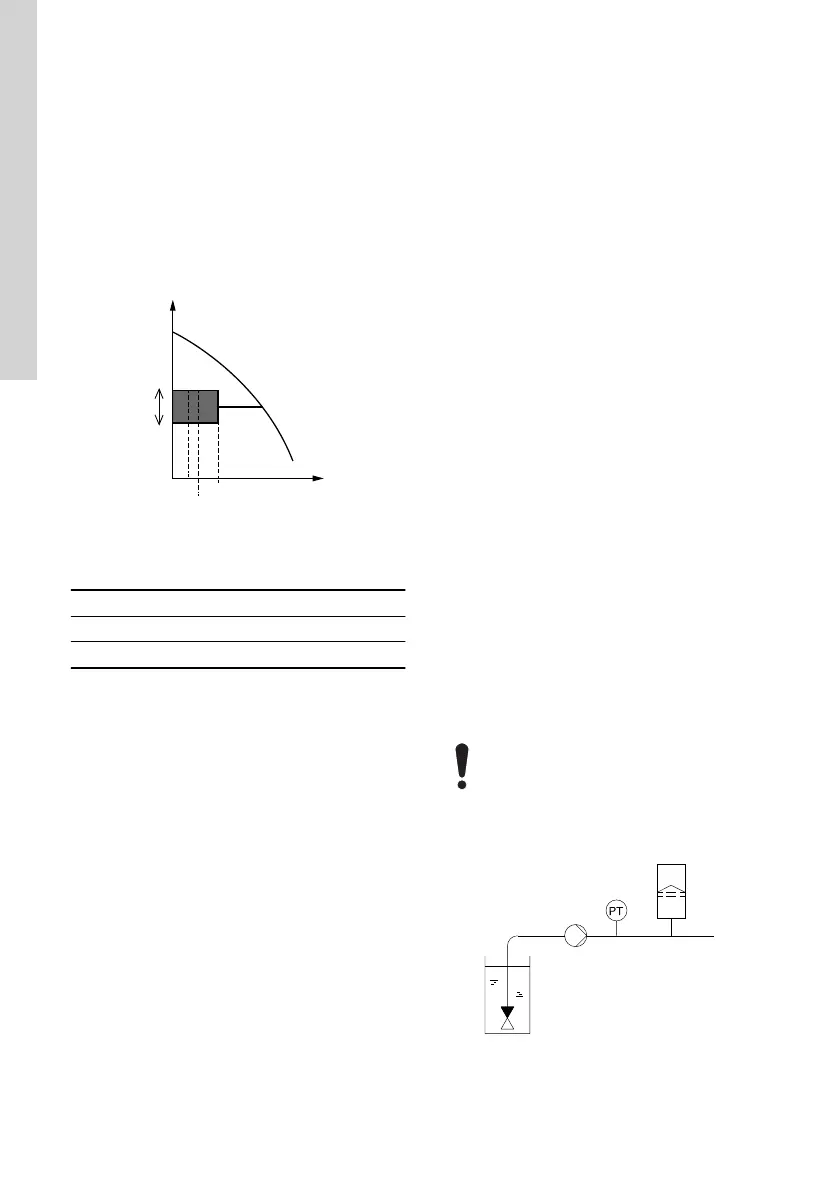

• High-comfort mode: The pump automatically

adjusts the parameters for the stop function so

that the disturbances during the start-stop

operation period are minimised. In this case, the

stop function uses the factory-set values of the

minimum flow (Q

min2

) and other internal

parameters. See the figure below.

• User-defined mode (Customised operating

mode): The pump uses the parameters set for ΔH

and minimum flow (Q

min3)

respectively for the stop

function. See the figure below.

Q

Q min2

Q min1

Q min3

H

△ H

1

2

TM064267

Difference between start and stop pressures (ΔH)

and minimum flow rate

Pos. Description

1 Stop pressure

2 Start pressure

In start-stop operation, the pressure varies between

the start and stop pressures. See the figure above.

In User-defined mode (Customised operating

mode), ΔH has been factory-set to 10 % of the actual

setpoint. ΔH can be set within the range from 5 to 30

% of the actual setpoint.

The pump changes to start-stop operation if the flow

becomes lower than the minimum flow rate.

The minimum flow rate is set in percentages of the

nominal flow rate of the pump. See the pump

nameplate.

In User-defined mode (Customised operating

mode), the minimum flow rate has been factory-set to

10 % of the nominal flow rate.

Factory setting

See the section on factory settings.

Low-flow stop function

A low flow can be detected in two ways:

1. A built-in low-flow detection function which is

active if none of the digital inputs are set for flow

switch.

• Low-flow detection function: The pump checks

the flow regularly by reducing the speed for a

short time. If there is no or only a small change

in pressure, this means that there is low flow.

The speed is increased until the stop pressure

(actual setpoint + 0.5 × ΔH) is reached and the

pump stops. When the pressure has fallen to

the start pressure (actual setpoint - 0.5 × ΔH),

the pump restarts.

• If the flow rate is higher than the set minimum

flow rate, the pump returns to continuous

operation at constant pressure.

• If the flow rate is still lower than the set

minimum flow rate (Q

min

), the pump continues

in start-stop operation until the flow rate is

higher than the set minimum flow rate (Q

min

).

When the flow rate is higher than the set

minimum flow rate (Q

min

), the pump returns to

continuous operation.

2. A flow switch connected to one of the digital

inputs.

• Flow switch: When the digital input is activated

for more than 5 seconds because there is low

flow, the speed is increased until the stop

pressure (actual setpoint + 0.5 x ΔH) is

reached, and the pump stops. When the

pressure has fallen to start pressure, the pump

restarts. If there is still no flow, the pump

quickly reaches the stop pressure and stops. If

there is flow, the pump continues operating

according to the setpoint.

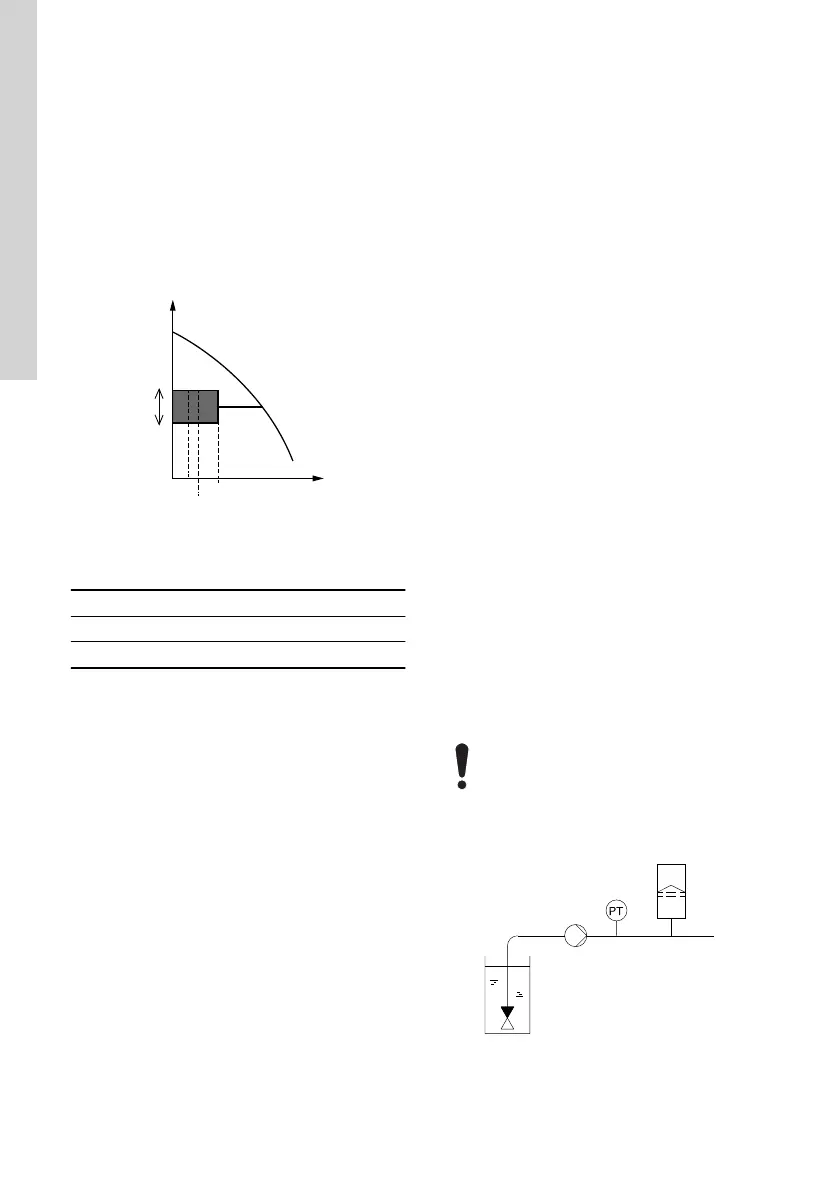

Operating conditions for the low-flow stop

function

You can only use the stop function if the system

incorporates a pressure sensor, a non-return valve

and a diaphragm tank.

Always install the non-return valve before

the pressure sensor.

See the figures below.

TM038582

Position of the non-return valve and pressure

sensor in system with suction lift operation

68

English (GB)

Loading...

Loading...