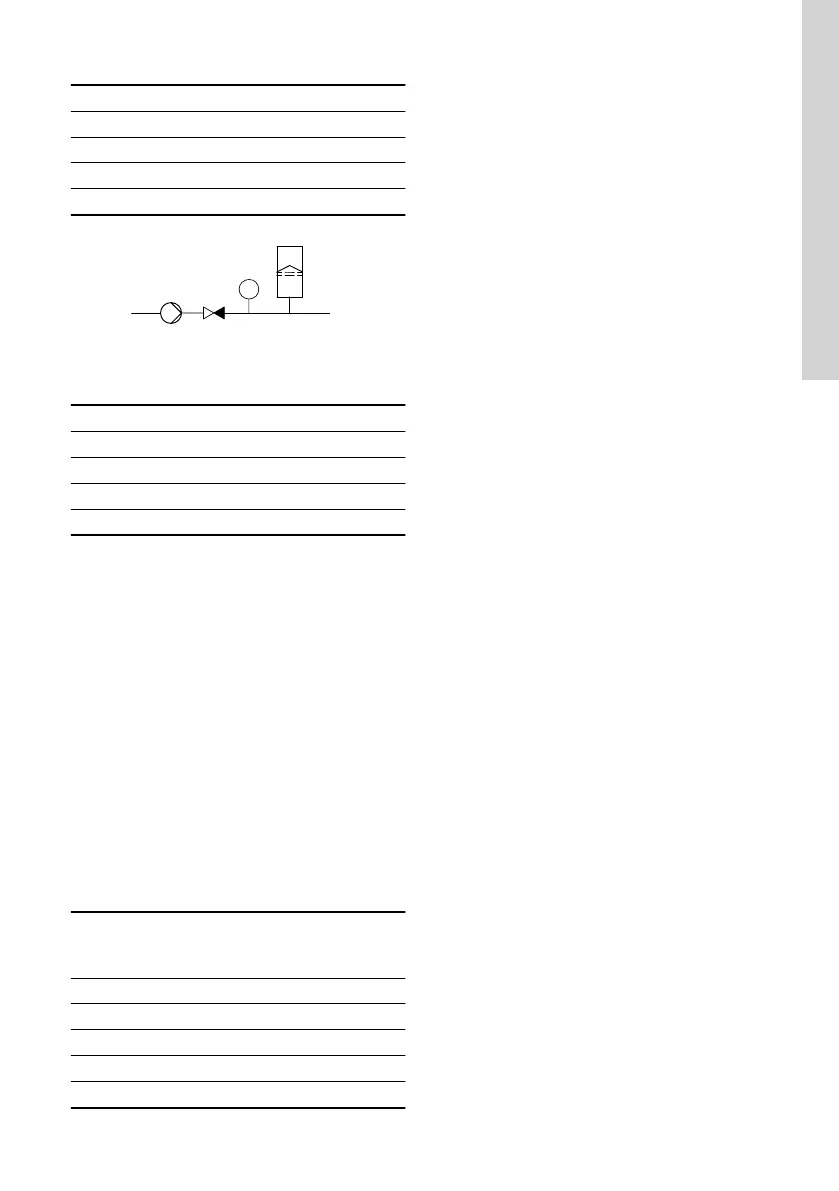

Pos. Description

1 Non-return valve

2 Pump

3 Pressure sensor

4 Diaphragm tank

TM038583

Position of the non-return valve and pressure

sensor in a system with a positive inlet pressure

Pos. Description

1 Pump

2 Non-return valve

3 Pressure sensor

4 Diaphragm tank

Set minimum flow

Set the minimum flow rate (Q

min

) in this display. This

setting determines at which flow rate the system is to

change from continuous operation at constant

pressure to start-stop operation. The setting range is

5 to 30 % of the rated flow rate.

Factory setting

See the section on factory settings.

Diaphragm tank volume

The stop function requires a diaphragm tank of a

certain minimum size. Set the size of the installed

tank in this display.

To reduce the number of start-stops per hour or to

reduce the ΔH, install a larger tank.

Install the tank immediately after the pump. The

precharge pressure must be 0.7 × actual setpoint.

Recommended diaphragm tank size:

Rated flow rate of

pump

[m

3

/h]

Typical diaphragm tank

size

[litres]

0-6 8

7-24 18

25-40 50

41-70 120

71-100 180

Factory setting

See the section on factory settings.

Related information

9.58 Factory settings for Grundfos GO

9.24 Stop at min. speed

This stop function can be utilised in for example

constant level applications where a boost of pressure

is not needed. It is a different type of stop function

than low-flow stop but the purpose is the same. The

pump stops if there is no or low consumption.

This function monitors the speed of the pump. When

the PI-controller has forced the speed of the pump to

minimum according to the feedback value, the pump

stops after a set period of time. It remains stopped

until the feedback value starts to drop and the PI-

controller starts the pump again.

• Enable Stop at min. speed

Enables the function Stop at min. speed.

• Delay

The delay time the pump must be running at

minimum speed before it stops.

• Restart speed

Speed in percentage when the pump must start

again, hysteresis. It must be set higher than the

minimum speed of the pump.

69

English (GB)

Loading...

Loading...