If the power supply is switched off, the deceleration of

the product only depends on the load and inertia.

TM069798

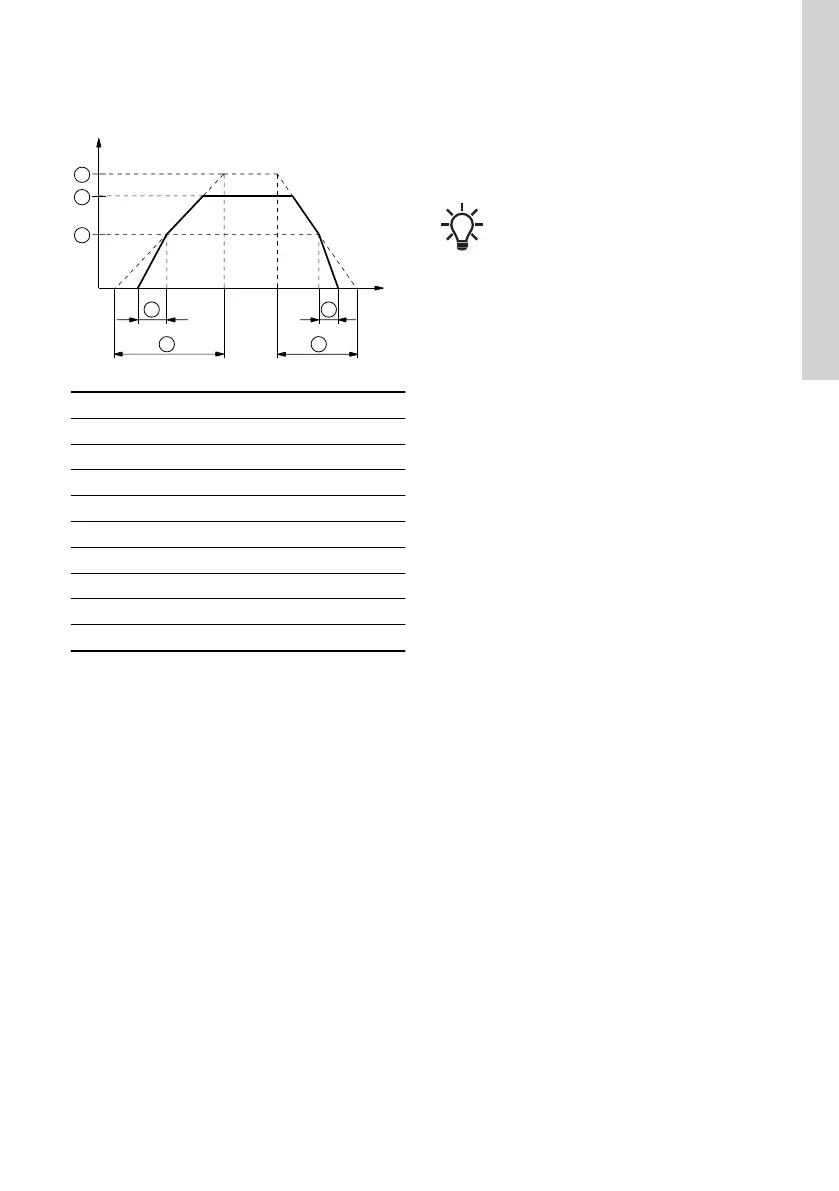

Pos. Description

Y Speed

X Time

1 Fixed maximum

2 User-set maximum

3 User-set minimum

4 Fixed initial ramp

5 Fixed final ramp

6 Ramp time up

7 Ramp time down

9.28 Direction of rotation

Use this function to select the desired direction of

motor rotation when looking at the motor shaft end

from the drive side.

• clockwise

• counterclockwise

The displayed direction of rotation applies when the

digital inputs for reversing the rotation are not active.

9.29

Skip band

Use this function to select a skip band within the

range from user-set minimum speed to user-set

maximum speed if continuous operation is not

required. The upper and lower speeds are stated in

percentage of rated speed.

The purpose of the skip band is to avoid certain

speeds which may cause noise or vibrations. If no

skip band is required, select -.

9.30

Standstill heating

Use this function to avoid condensation in humid

environments.

When you set the function to

Active and the product

is in operating mode Stop, a low AC voltage is

applied to the motor windings. The voltage is not high

enough to make the motor rotate, but ensures that

sufficient heat is generated to avoid condensation in

the product, including the electronic parts in the drive.

Remember to remove the drain plugs and

fit a cover over the product.

9.31 Alarm handling

This setting determines how the pump must react in

case of a sensor failure.

Alarm or warning types:

• Warning

A warning. There is no change in the operating

mode.

• Stop

The pump stops.

• Min.

The pump reduces the speed to minimum.

• Max.

The pump increases the speed to maximum.

• User defined speed

The pump runs at the speed set by the user.

Affected inputs:

• Analog input 1

• Analog input 2

• Analog input 3

• Built-in Grundfos sensor

• Pt100/1000 input 1

• Pt100/1000 input 2

• Liqtec input.

9.32

Motor bearing monitoring

Use this function to select whether or not you want to

monitor the motor bearings.

You can make the following settings:

• Active

• Not active

When the function is set to Active, a counter in the

controller starts counting the running hours of the

bearings. The running hours are calculated on the

basis of the motor speed. When a predefined limit is

reached, a warning indicates that the bearings must

be replaced or relubricated.

71

English (GB)

Loading...

Loading...