9.25 Pipe filling function

This function is typically used in pressure-boosting

applications and ensures a smooth startup of systems

with for instance empty pipes.

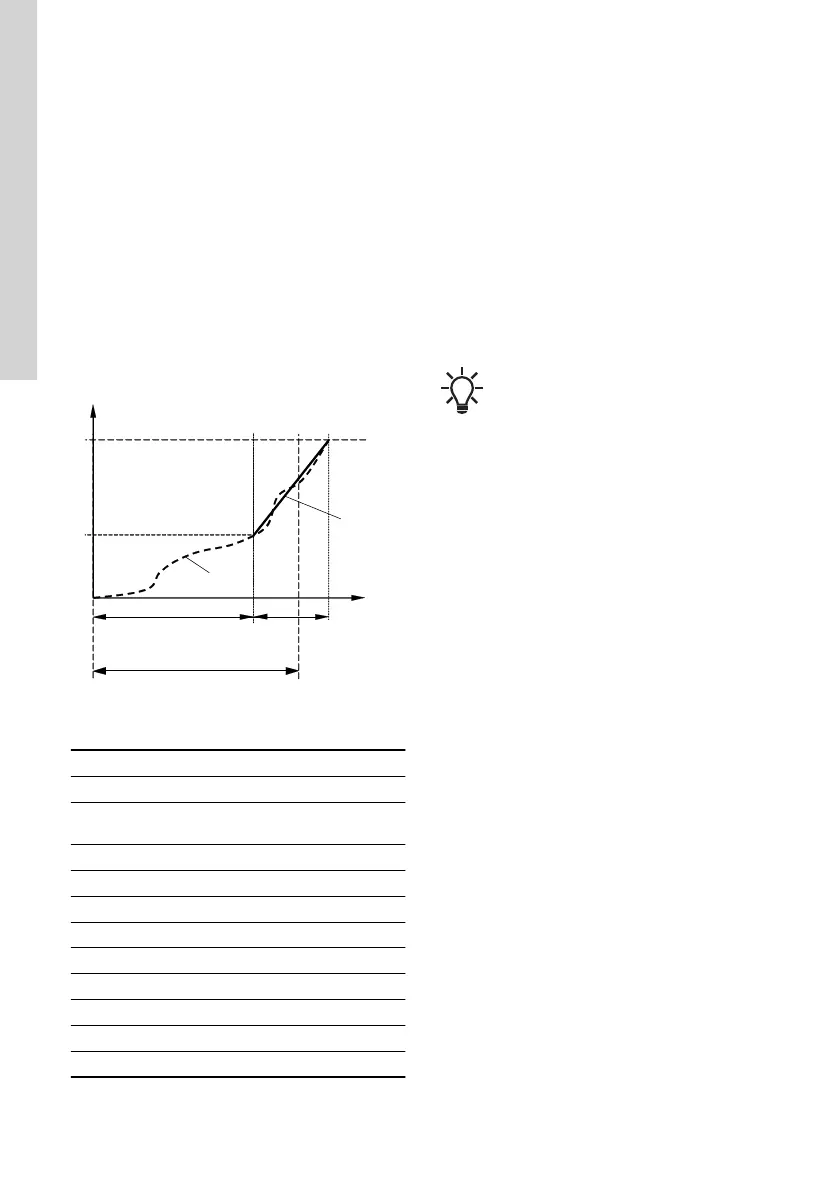

Startup takes place in two phases. See the figure

below.

1. Filling phase. The pipes are slowly filled with

water. When the pressure sensor of the system

detects that the pipes have been filled, phase two

begins.

2. Pressure build-up phase. The system pressure is

increased until the setpoint is reached. The

pressure build-up takes place over a pressure

build-up time. If the setpoint is not reached within

a given time, a warning or an alarm can be given,

and the pumps can be stopped at the same time.

TM039037

Filling and pressure build-up phases

Pos. Description

1 Filling phase (constant-curve operation)

2

Pressure build-up phase (constant-pressure

operation)

3 Setpoint

4 Filling pressure

5 Actual value

6 Setpoint ramp-up

7 Filling time

8 Pressure build-up time

9 Maximum filling time

P Pressure

t(s) Time (sec)

Setting range

• Filling speed. Fixed speed of the pump during

the filling phase.

• Filling pressure. The pressure that the pump

must reach before the maximum filling time.

• Max. filling time. The time in which the pump

must reach the filling pressure.

• Max. time reaction. Reaction of the pump if the

maximum filling time is exceeded:

- warning

- alarm (pump stops).

• Pressure build-up time. Ramp time from when

the filling pressure is reached until the setpoint

must be reached.

When you activate this function, the

function always starts when the pump has

been in operating mode Stop and is

changed to Normal.

Factory setting

See the section on factory settings.

Related information

9.58 Factory settings for Grundfos GO

9.26 Pulse flowmeter (Pulse flowmeter

setup)

You can connect an external pulse flowmeter to one

of the digital inputs in order to register the actual and

accumulated flows. Based on this, you can also

calculate the specific energy.

To enable a pulse flowmeter, set one of the digital-

input functions to Accumulated flow and set the

pumped volume per pulse.

Factory setting

See the section on factory settings.

Related information

9.12 Digital inputs

9.58 Factory settings for Grundfos GO

9.27

Ramps

The ramps determine how quickly the product can

accelerate and decelerate during start and stop or

setpoint changes.

You can make the following settings:

• acceleration time, 0.1 to 300 s

• deceleration time, 0.1 to 300 s.

The times apply to the acceleration from 0 rpm to a

fixed maximum speed and the deceleration from a

fixed maximum speed to 0 rpm, respectively.

At short deceleration times, the deceleration of the

product may depend on load and inertia as there is

no possibility of actively braking the product.

70

English (GB)

Loading...

Loading...