TM070085

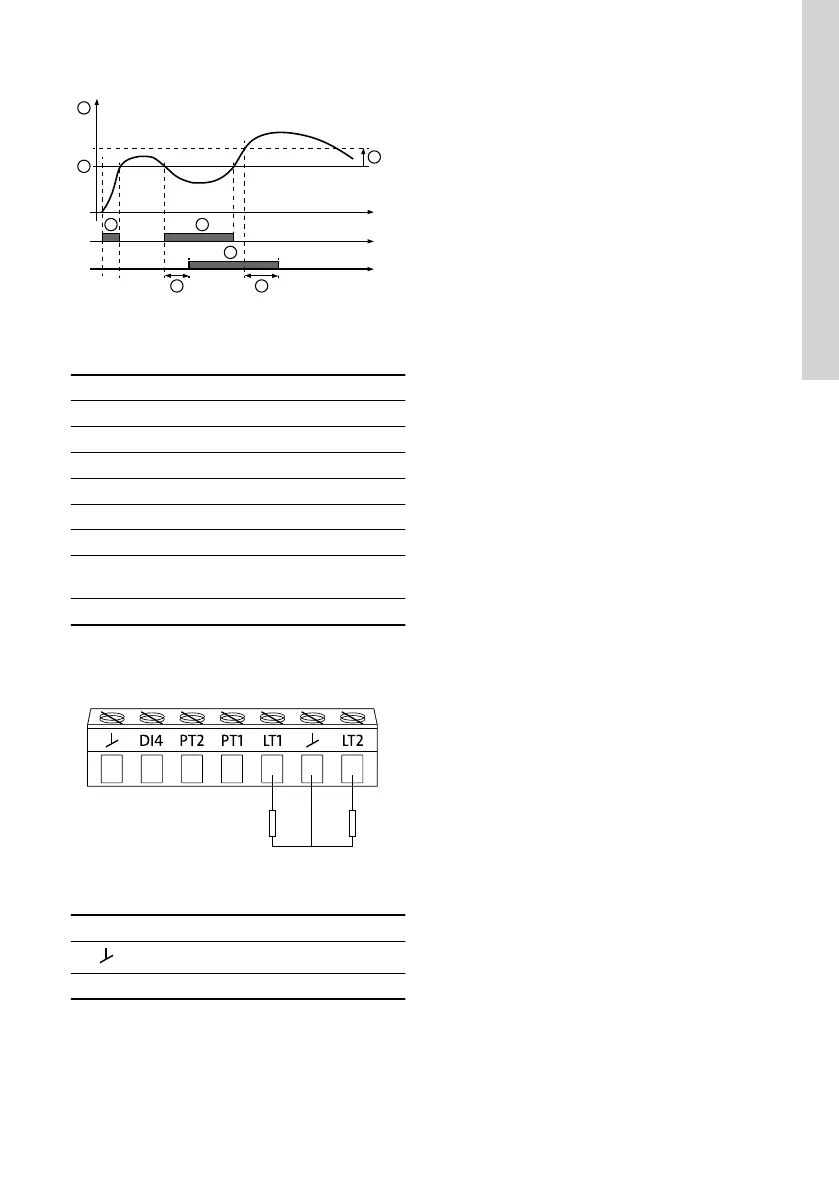

X: Time in seconds

Y: Pressure in bar

Pos. Parameter Setting

1 Measured Discharge pressure

2 Limit 5 bar

3 Hysteresis band 2 bar

4 Limit exceeded when below limit

5 Detection delay 5 seconds

6 Resetting delay 8 seconds

A

Limit-exceeded

function active

-

- Action Warning

9.22 LiqTec (LiqTec function)

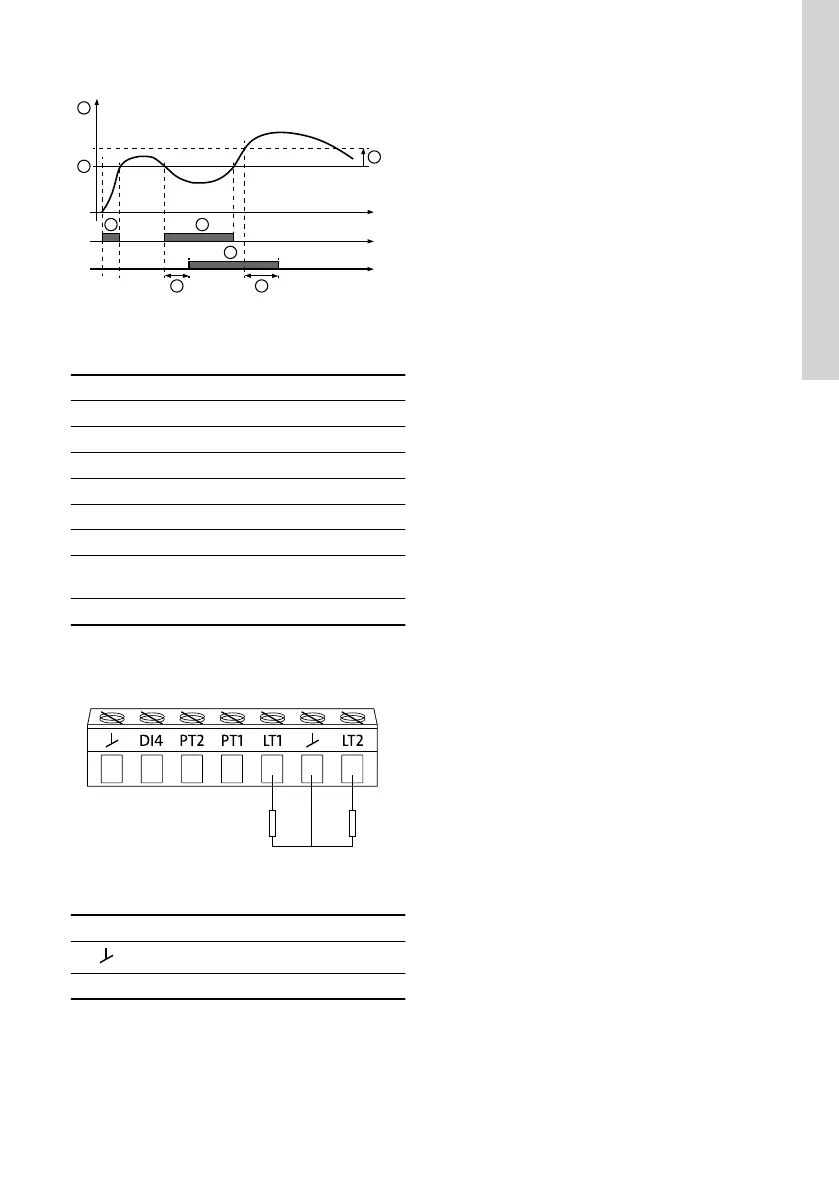

Wiring example:

TM083190

LiqTec

LT1 White wire

Brown and black wires

LT2 Blue wire

You can enable the function of the LiqTec sensors in

the display. A LiqTec sensor protects the pump

against dry running.

The function requires that a LiqTec sensor has been

fitted and connected to the pump.

When you have enabled the LiqTec function, it stops

the pump if dry running occurs. Restart the pump

manually if it has been stopped due to dry running.

Dry-running detection delay

You can set a detection delay to make sure that the

pump is given a chance to start up before the LiqTec

function stops the pump due to dry running.

Range: 0-254 seconds.

Factory setting

See the section on factory settings.

Related information

9.58 Factory settings for Grundfos GO

9.23 Stop function (Low-flow stop function)

You can set Low-flow stop function to these values:

• Not active

• Energy-optimal mode

• High-comfort mode

• User-defined mode (Customised operating

mode).

When the low-flow stop function is active, the flow is

monitored. If the flow becomes lower than the set

minimum flow (Q

min

), the pump changes from

continuous operation at constant pressure to start-

stop operation and stops if the flow reaches zero.

The advantages of enabling Low-flow stop function

are the following:

• no unnecessary heating of the pumped liquid

• reduced wear of the shaft seals

• reduced noise from operation.

The disadvantages of enabling Low-flow stop

function may be the following:

• The delivered pressure is not completely constant

as it fluctuates between the start and stop

pressures.

• The frequent starts and stops of the pump may in

some applications cause acoustic noise.

The impact of the above disadvantages very much

depends on the setting selected for the stop function.

The High-comfort mode setting minimises pressure

fluctuations and acoustic noise.

Select Energy-optimal mode if the main priority is to

reduce the energy consumption as much as possible.

Possible settings of the stop function:

• Energy-optimal mode The pump automatically

adjusts the parameters for the stop function so

that the energy consumption during the start-stop

operation period is minimised. In this case, the

stop function uses the factory-set values of the

minimum flow (Q

min1

) and other internal

parameters. See the figure below.

67

English (GB)

Loading...

Loading...