English (GB)

13

4.2 Hydraulic connection

Important information on installation

• Observe suction lift and line diameter, see

section 3.1 Technical data.

• Shorten hoses at right angles.

• Ensure that there are no loops or kinks in the

hoses.

• Keep suction line as short as possible.

• Route suction line up towards the suction valve.

• Installing a filter in the suction line protects the

entire installation against dirt and reduces the

risk of leakage.

• Only control variant FC/FCM: For discharge

quantities < 1 l/h we recommend the use of an

additional spring-loaded valve (approx. 3 bar) on

the discharge side for the safe generation of the

necessary differential pressure.

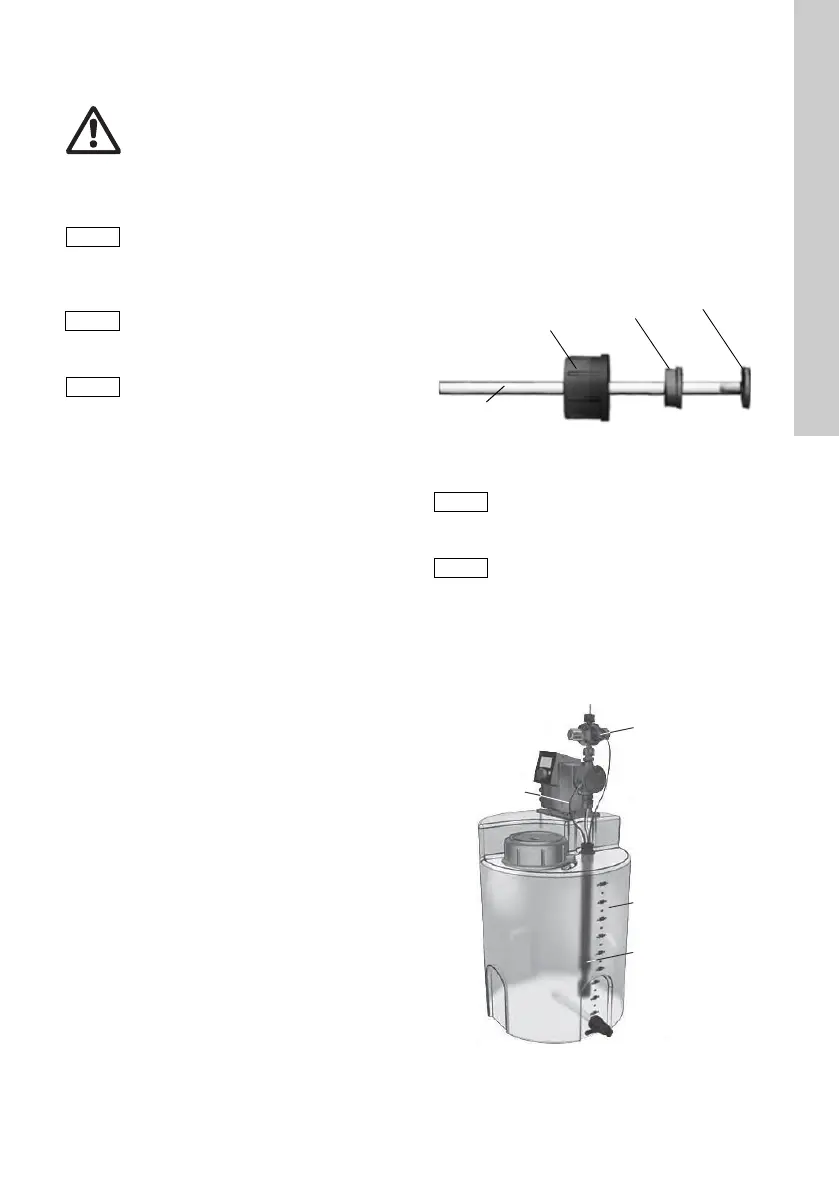

Hose connection procedure

1. Push union nut and tensioning ring across hose.

2. Push cone part fully into hose, see fig. 8.

3. Attach cone part with hose to corresponding

pump valve.

4. Tighten union nut manually.

– do not use tools!

5. Tighten up union nuts after 2-5 operating hours if

using PTFE gaskets!

6. Attach deaeration hose to the corresponding

connection (see fig. 3) and run into a container

or a collecting tray.

Fig. 8 Hydraulic connection

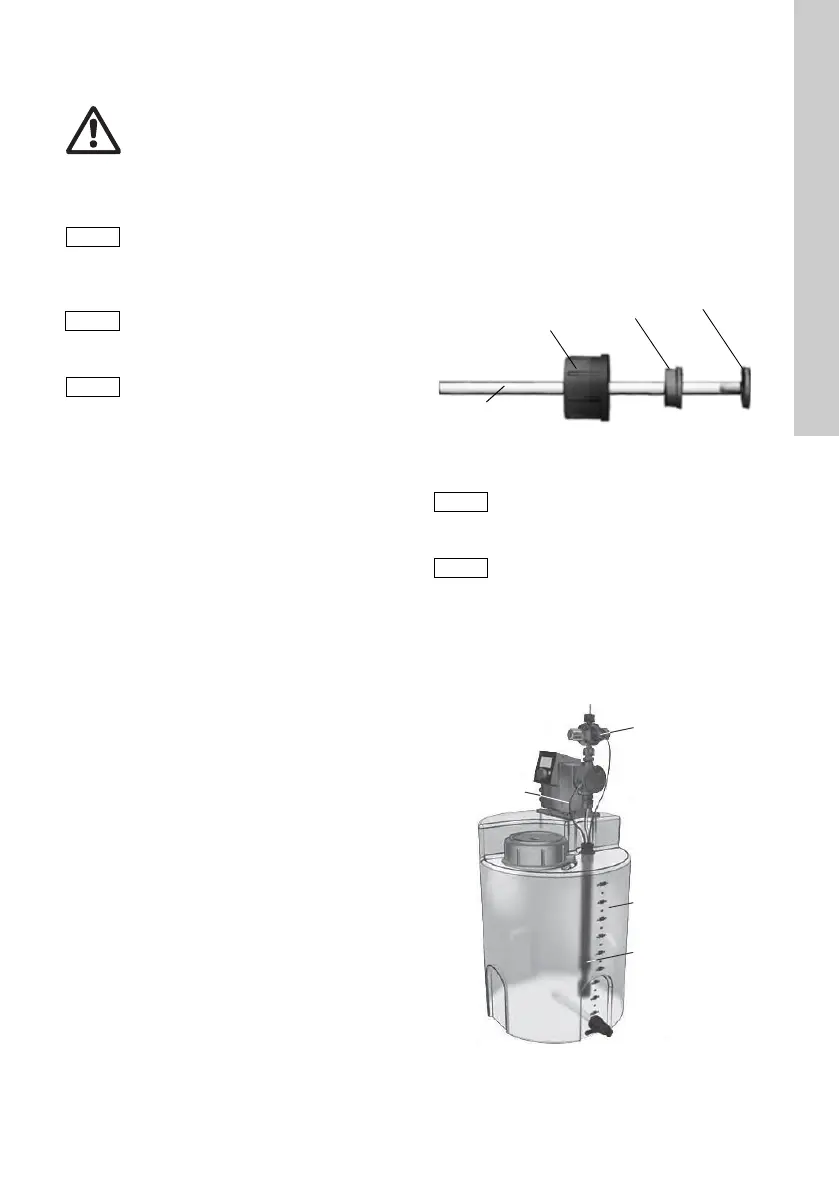

Installation example

The pump offers various installation options. In the

picture below, the pump is installed in conjunction

with a suction line, level switch and multifunction

valve on a Grundfos tank.

Fig. 9 Installation example

Warning

Risk of chemical burns!

Wear protective clothing (gloves and

goggles) when working on the dosing

head, connections or lines!

The dosing head may contain water

from the factory check!

When dosing media which should not

come into contact with water, another

medium must be dosed beforehand!

Faultless function can only be

guaranteed in conjunction with lines

supplied by Grundfos!

The lines used must comply with the

pressure limits as per section

3.1 Technical data!

TM04 1155 0110

Pressure differential between suction

and discharge side must be at least

1 bar / 14.5 psi!

Tighten up the dosing head screws

once before commissioning and after

2-5 operating hours at 3 Nm.

TM04 1183 0110

Union nut

Tensioning ring

Cone part

Hose

Deaeration

hose

Tank

Multifunction

valve

Suction line

with empty

signal

Loading...

Loading...