Installation Guide

ORCA Sonar System

12

ORCA Transmitter – Mounting Requirements

Select a suitable mounting position, preferably not in

direct sunlight. If necessary utilize a sunshade.

Observe the maximum and minimum temperature

specification.

Do not mount the sonar transmitter near high sources

of EMF, such as motor starters, variable speed drives

or 3 phase cables. Avoid mounting in high vibration

areas, or use rubber absorption mounts.

Be careful when removing the cable and compression

glands.

Installation Guide

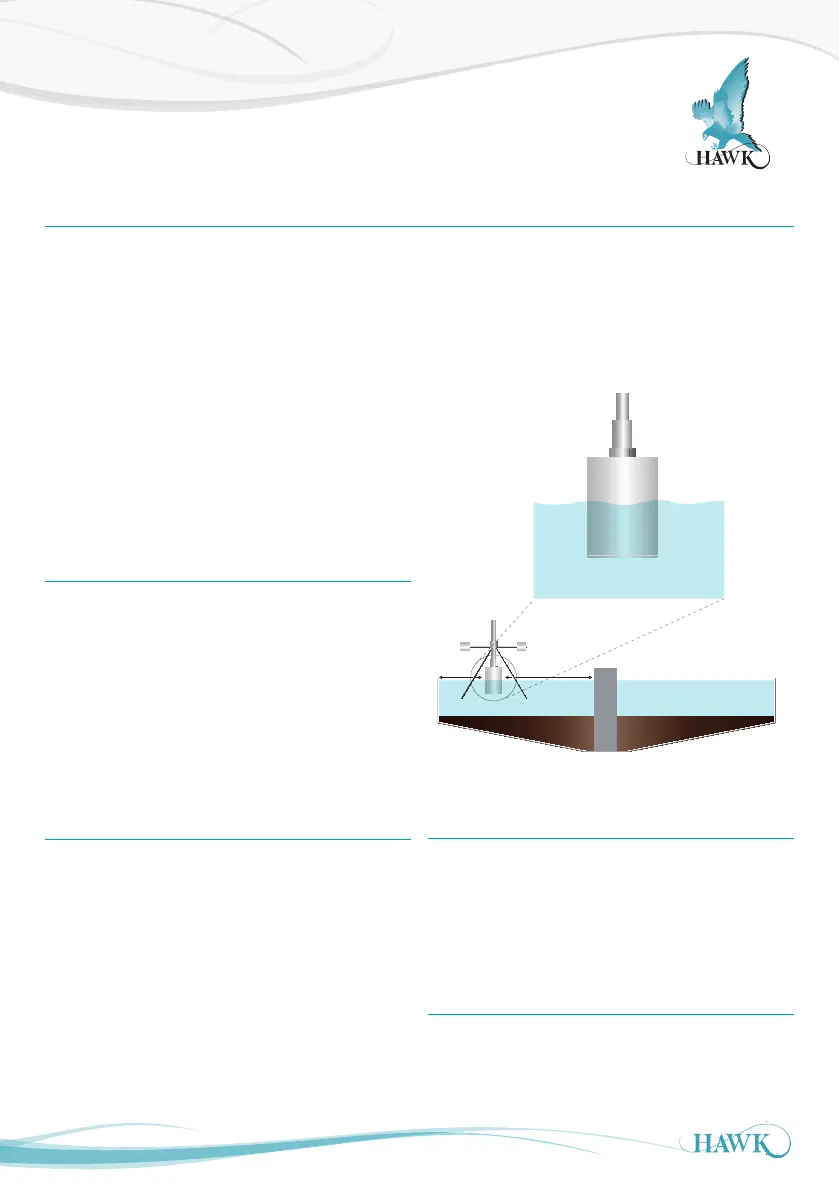

Sonar Transducer – Mounting Requirements

The transducer should be half submerged in the liquid

and the transducer face must always be submerged.

Wrap cable entry and lower connection cable with

Teflon tape

Round Tanks – Centre Feedwell

Mount the sonar transducer and cleaning mechanism,

approximately one third radius between the outside

tank wall and the feedwell. This is the same whether it

is a moving or fixed bridge installation.

Do not mount near high infeed turbulence.

Choose a site installation where the infeed is least

disturbed.

High Level

20mA

0.500m

Low Level

4mA

X.xxm

Blanking /

non-measured

zone

1/2 Submerged

1/3 Radius

Rectangular Tanks – End Feed

Mount the sonar transducer and cleaning mechanism

away from high infeed turbulence. A clearance of

700mm from the side wall.

Do not mount directly over scraper, chain

mechanisms. Choose a site installation where the

infeed is least disturbed.

Ball oat

Mount the floating sonar transducer and cleaning

mechanism as close as practicable to the launders.

Mount at least 1.00 metres from side walls. Ensure

alignment guides are installed on the mounting

bracket for decanter ranges above 500mm.

Impact Plates

Leave an extra 2 turns of cable where the transducer

connects to the actuator to minimise stress and wear

on the cable (see Impact Plate Assembly).

Loading...

Loading...