35

Routine inspection and maintenance of the device will guarantee the highest quality prints and helps you to increase the reliability of

your printer. Your failure to perform these operations will speed up the wear of your printer and increased risk of failures.

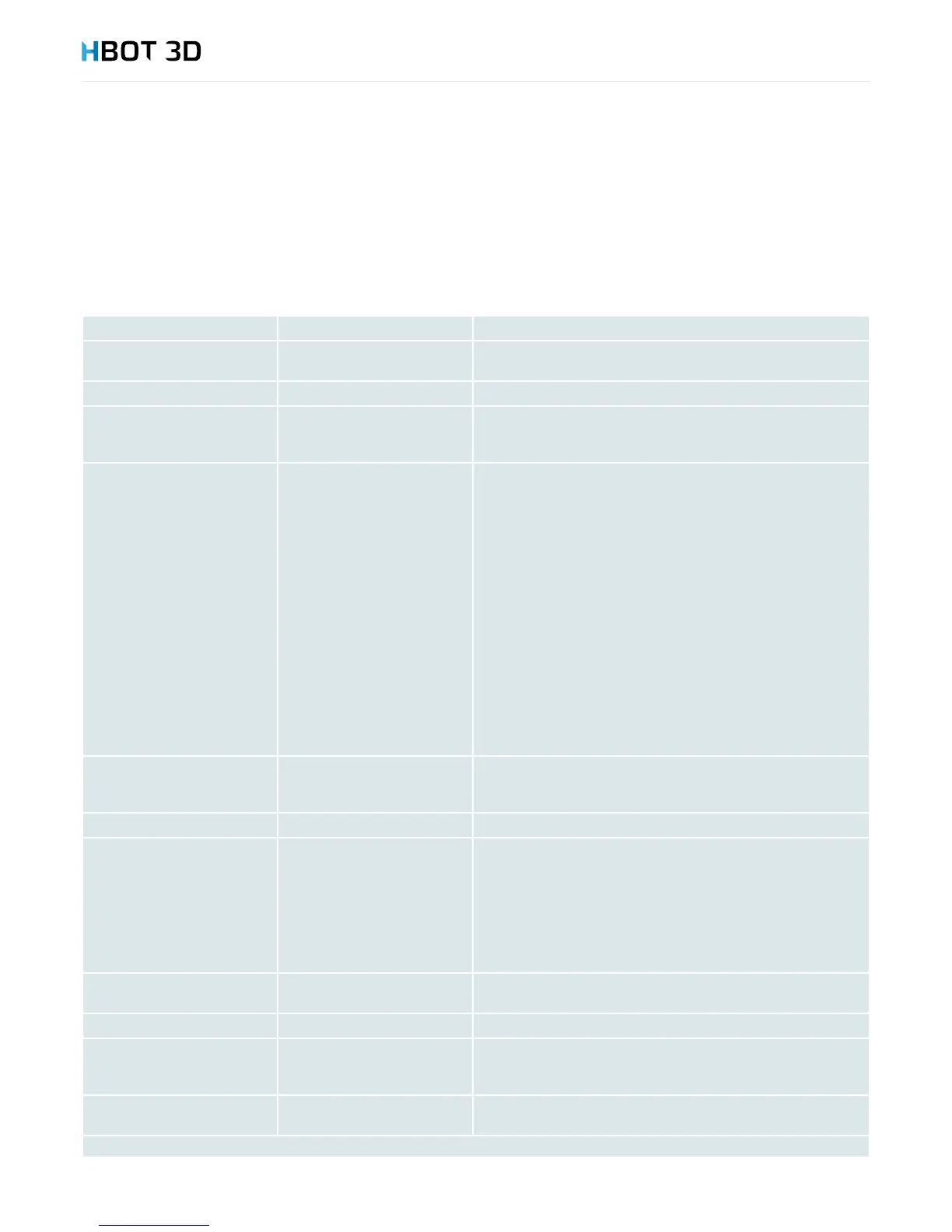

7.1 RECOMMENDED MAINTENANCE OPERATIONS

Repairs or maintenance must be made after power has been cut off to your printer.

Operation Frequency Instructions

Printer cleaning Before each print Remove unnecessary items and excessive dust from printer

interior and clear air fans

Cleaning the build platform Before each print Wash the platform under running water and wipe it dry

Applying Dimax adhesive Before each print Before putting the printing platform back into the printer, apply

a thin layer of Dimax spray on its upper surface (outdoors or in a

ventilated room)

Exchanging Kapton lm If damaged Should either a torn portion of Kapton lm, or noticeable

scratches be present that would affect print quality, carefully

remove the worn Kapton lm. Wash and dry the glass platform

thoroughly. Unstick, pull off, and hold the rst 30 mm piece of

adhesive securing lm from a new Kapton sheet (shorter edge

of the lm). Lay the beginning of the Kapton lm, the adhesive

side down, onto the shorter edge of glass platform so that it

overhangs ca. 5 mm beyond the platform edge, then carefully

stick the lm on platform edge. Hold down the stuck portion of

the Kapton lm with a squeegee and pressing the lm against the

glass, slowly move the squeegee along the lm so that the entire

Kapton lm is stuck to the platform. The securing lm should

unstick itself as you move the squeegee. To increase slippage of

the squeegee, spray the Kapton lm with a small amount of glass

cleaner. Trim the excess of the Kapton lm on longer sides of the

glass platform, ush with platform edge. Using a ruler, trim the

lm on shorter sides of the platform, 5 mm from platform edge, to

expose the glass surface.

Nozzle replacement If damaged Print nozzle replacement must be made if the nozzle gets

overheated or deformed. (Refer to chapter "Nozzle replacement"

on page 19).

Print head replacement Every 12 months* or 4 000 h Contact the Service Department of the manufacturer

Lubricating guides Every 1 month* or 300 h Position the carriage in its middle position (SetupOperator

panel). Wipe away the old grease from the guides (with a paper

towel or clean cloth). Apply an amount of pea sized grease

amount to each guide at each bearing (4 carriage bearings, 2

bearings on the right Y-guide and 2 bearings on the left Y-guide).

Using the front, back, left and right buttons travel the carriage

along the entire operating range to spread the grease along the

guides

Belt tensioning Every 6 months* or 2 000 h Loosen 4 xing screws of the left stepper motor. Push the motor

back and tighten back the screws while holding the motor.

Printing platform leveling Once a week* or every 75 h See the "Printing platform leveling" chapter on page 13

Cleaning the knurled wheel Once a week* or every 75 h Clean the knurled wheel by blowing out with compressed air

through the hole in the extruder case so as to remove any leftover

lament chips.

Firmware update 1 month Once a month check on the manufacturer's website if an updated

software version, or new material congurations are available

* assuming that the average device operating time is 15 h/ day, 5 days/ week.

7. Maintenance and operation

Loading...

Loading...