Assembly Assembly

34 35

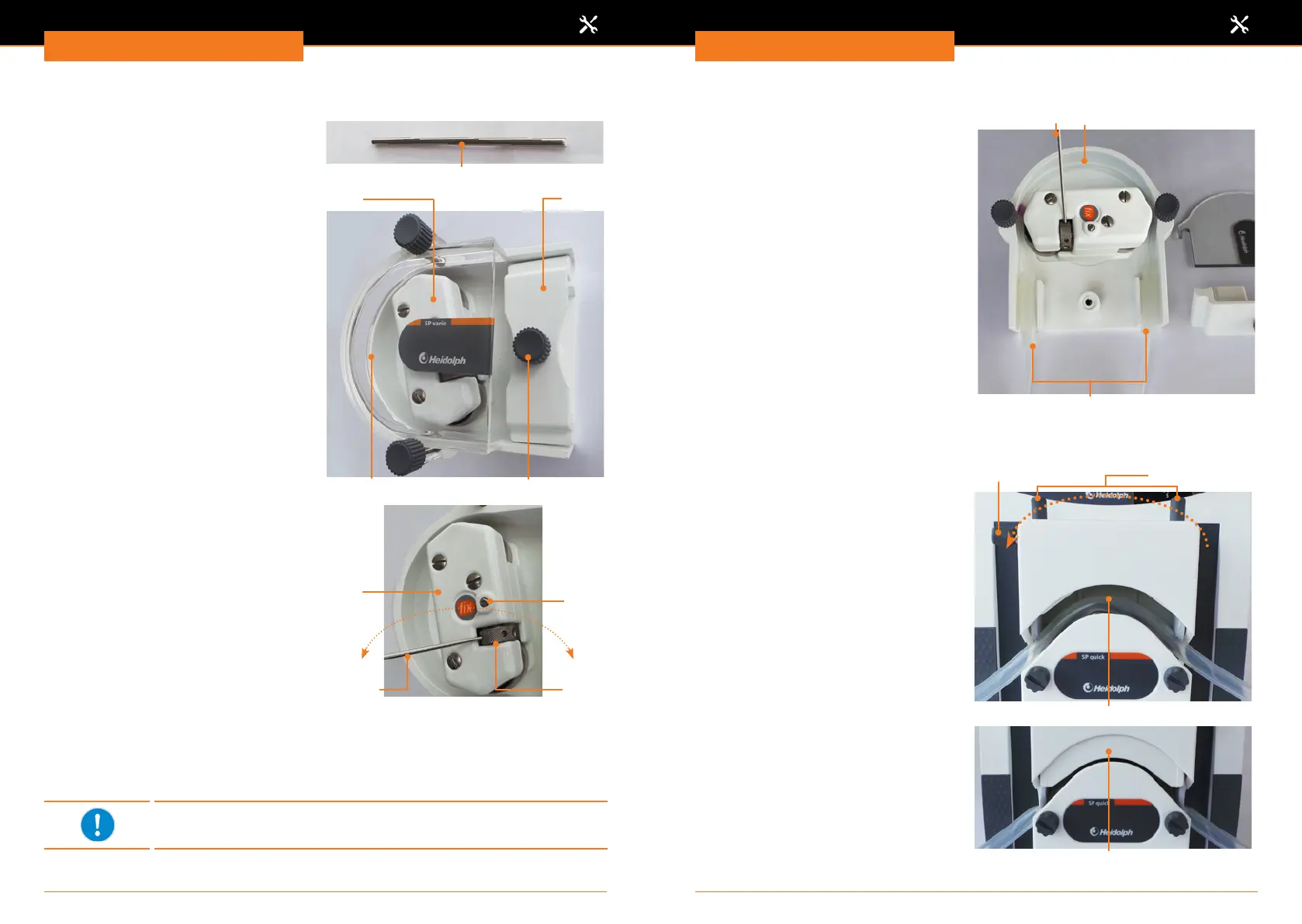

Tubes: pump head SP vario

Additional components:

1x Aid pin

Aid pin

Pump head SP vario allows operating

tubes of different wall thickness.

✓ Remove protection shield.

➜ Remove clamping screw to remove

clamp.

Clamping screw

Rotor

Clamp

Protection shield

➜ Turn vario wheel via aid pin to

maximum wall thickness.

➜ Mount tube in a curve of 180° into

tube bed.

➜ Turn rotor by hand till tube lies

between roller and tread.

➜ Turn vario wheel via aid pin to

minimum wall thickness till you

sense a noticeable resistance.

➜ Tighten xiing screw to hold vario

wheelin this position.

Vario

wheel

Rotor

Fixing

screw

Aid pin

maximum

minimum

➜ Turn rotor repeatedly to ensure tube is crushed by rollers in whole width.

➜ Attach clamp with clamping screws.

➜ Mount protection shield and secure with knurled screws.

➜ Check correct mounting by running a short test.

The right pressure is reached if uid is dispensed during operation but

stops passing through when pump is stopped.

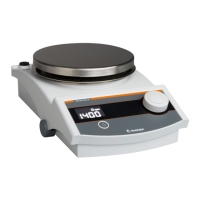

Small tubes, inner diameter 0.8 mm and 1.7 mm

Tubes with an inner diameter of

0.8 mm and 1.7 mm are delivered

with 2 additional tube cuttings.

Push both tube cuttings onto the

dispenser tube.

➜ Place tube in pump head with cuttings

positioned in clamping sleeve.

✓ The cuttings ensure save clamping of

the small tube.

Aid pin

Tube inner Ø 0.8 mm / 1.7mm

Tube cuttings

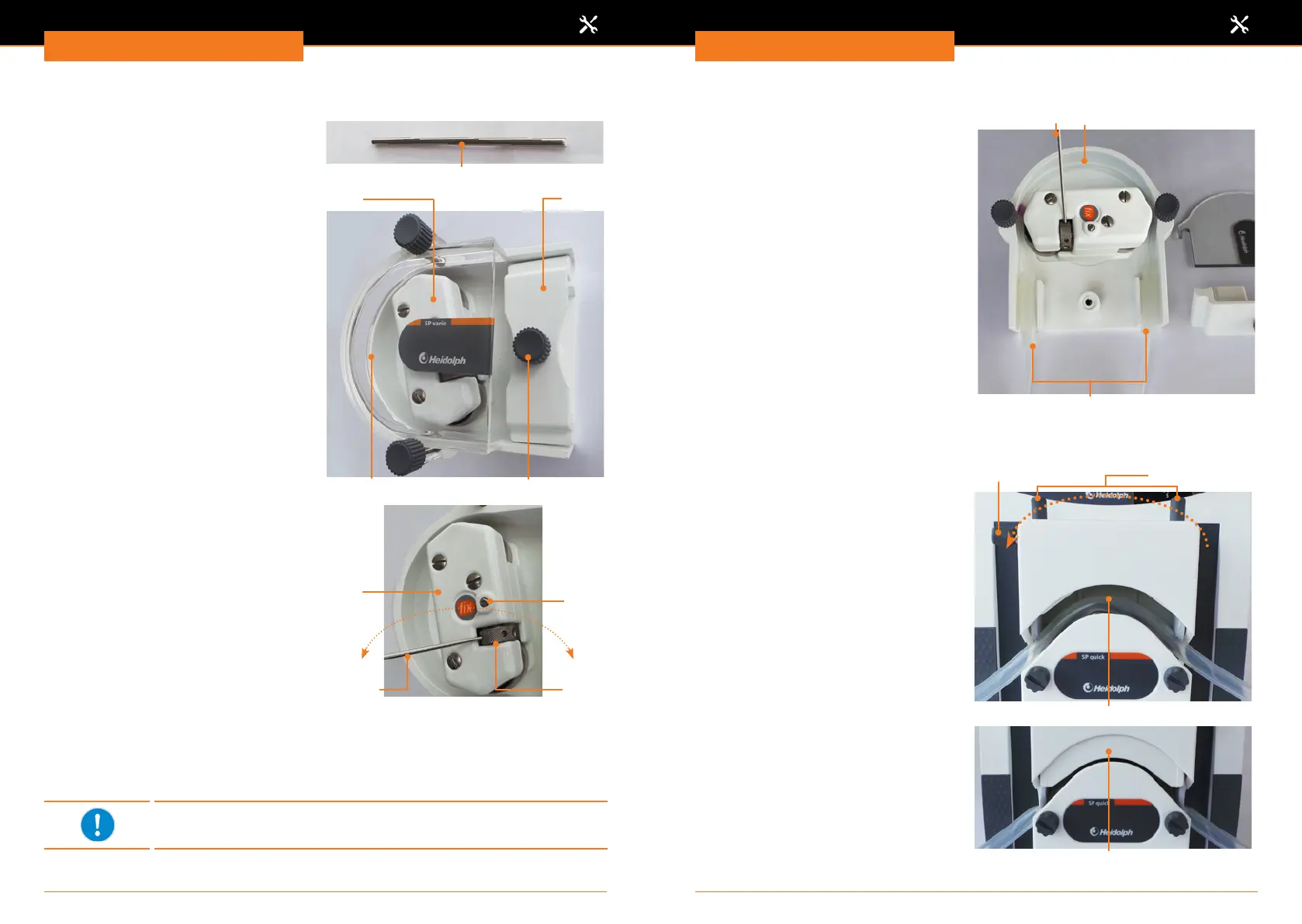

Tubes: pump head SP quick

Pump head SP quick features a quick-clamp

mechanic for clamping tubes.

➜ Move clamping lever to the left to open

tube bed.

➜ Turn both clamping screws counter-

clockwise as far as they will go for

maximum tube size.

Clamping screws

Clamping lever

Tube bed open

➜ Place tube into open tube bed.

➜ Move clamping lever cautiously to the

right to close tube bed.

✓ When sensing signicant resistance

during closing either clamping screws

are not open or tube is too large.

➜ Turn both clamping screws clockwise to

clamp tube.

➜ Check correct mounting by running a

short test.

Tube bed closed

Loading...

Loading...