Chapter 8. How to Use Position Servo

8-8

8.6.1 Inputting position command pulse

3 types of command pulses, ① A phase + B phase, ② CW pulse + CCW pulse and ③

direction + pulse, can be selected. Input applicable number to [Pulse Logic (P4-14)].

Command pulse operation is effected based on the encoder pulse value multiplied by 4.

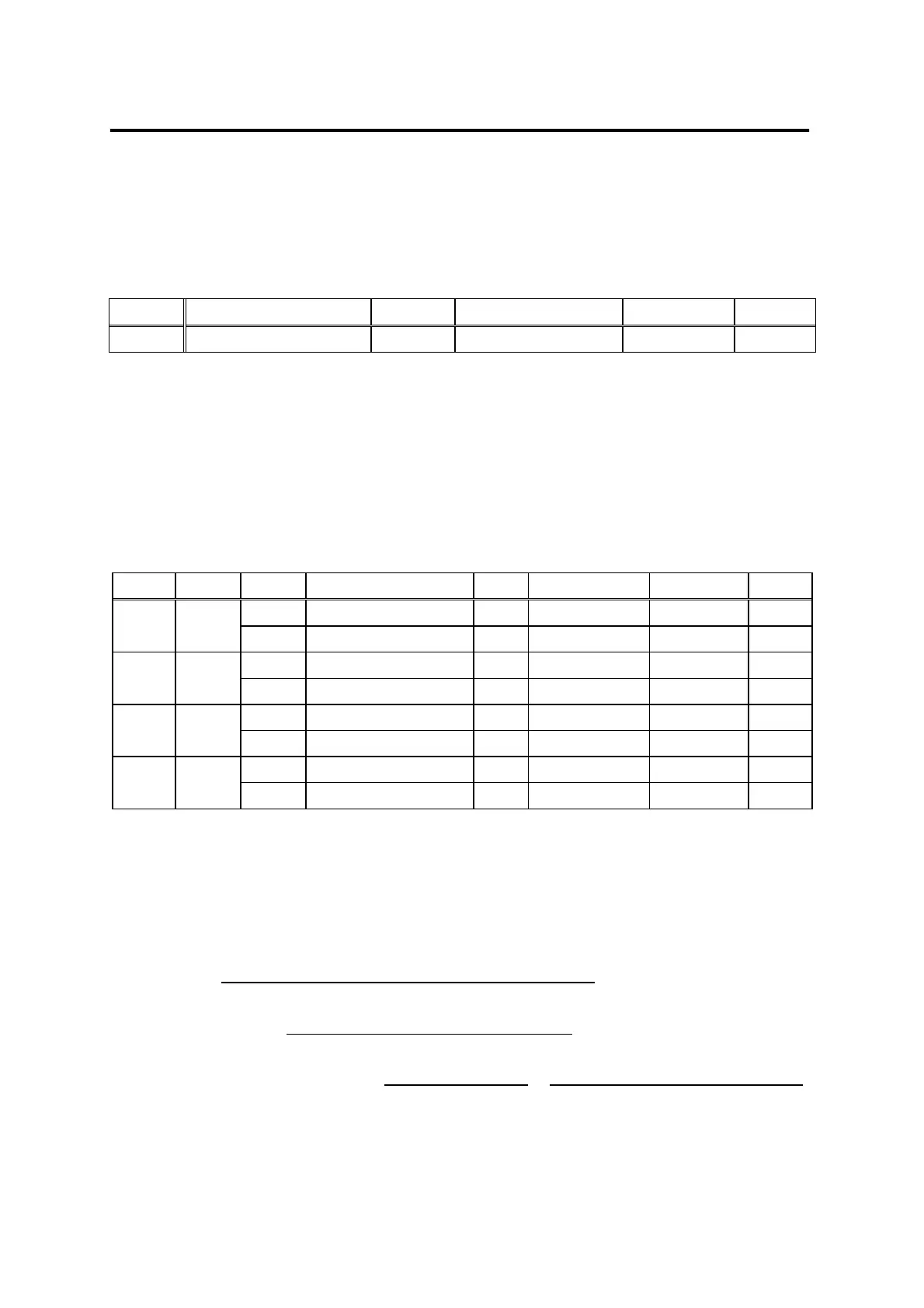

Menu Menu name Unit Display range Initial value Mode

P4-14 Pulse Logic 0 ~ 5 1 P

8.6.2 Electronic gear

The electronic gear enables setting of motor feed per input command pulse in a random

value. The electronic gear is multiplied by the number of the command pulses to

electronically play the role of a gear. FDA 5000 series are capable of inputting 4 different

electronic gear ratios, and the selection of the electronic gear is decided by the input

contacts (GEAR1) and (GEAR2).

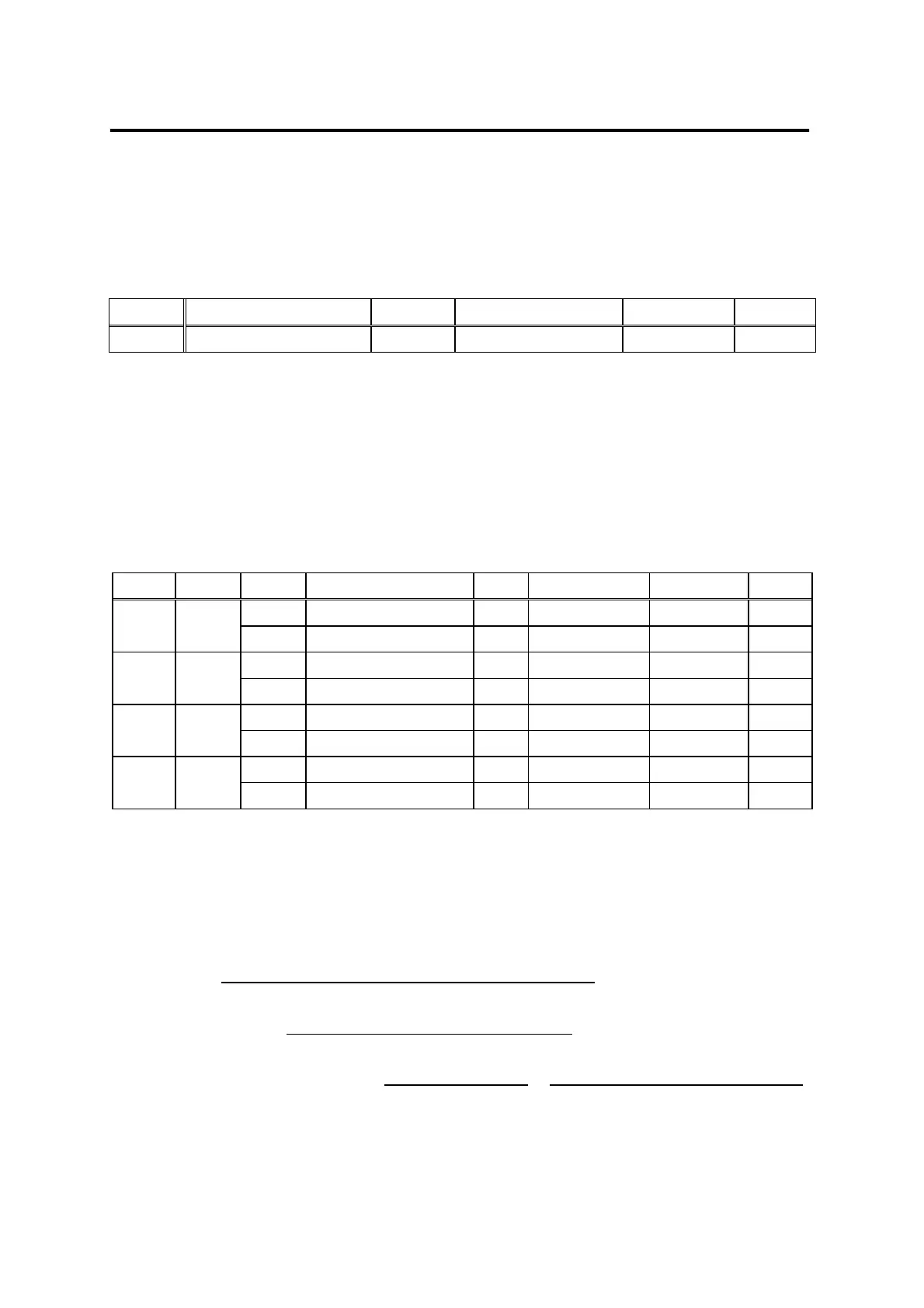

Gear 1 Gear 2 Menu Menu name Unit Display range Initial value Mode

P4-06 ELCTR Gear1 NUM 1 ~ 99999 1 P

OFF OFF

P4-07 ELCTR Gear1 DEN 1 ~ 99999 1 P

P4-08 ELCTR Gear2 NUM 1 ~ 99999 1 P

ON OFF

P4-09 ELCTR Gear2 DEN 1 ~ 99999 2 P

P4-10 ELCTR Gear3 NUM 1 ~ 99999 1 P

OFF ON

P4-11 ELCTR Gear3 DEN 1 ~ 99999 3 P

P4-12 ELCTR Gear4 NUM 1 ~ 99999 1 P

ON ON

P4-13 ELCTR Gear4 DEN 1 ~ 99999 4 P

[Setting Electronic Gear]

1) Determine the minimum unit (command unit) of the position data which feeds load per

pulse.

Assumed command unit = 0.001 [mm]/ pulse.

2) Obtain the load feed rate per load axis rotation in the unit of command.

Example) In case the ball screw pitch is 5[mm], and command unit is 0.001 [mm]/pulse.

Load feed per load axis rotation = 5/0.001 = 5000

3) Get electronic gear ratio in case of reduction ratio (n/m).

Number of motor encoder pulse x 4

Electronic gear ratio =

Feed per load axis rotation

X

(motor axis speed) Electronic gear ratio (numerator)

reduction ratio

(load axis speed)

=

Electronic gear ratio

(denominator)

4) The results of calculating the electronic gear ratio must be between 0.05-20.

Loading...

Loading...