Chapter 12. How to Use Position/Torque Servo

12-1

12. How to Use Position/Torque Servo

12.1 Power Supply Wiring

For wiring, see "3.3 Main Circuit Terminal Board Wiring".

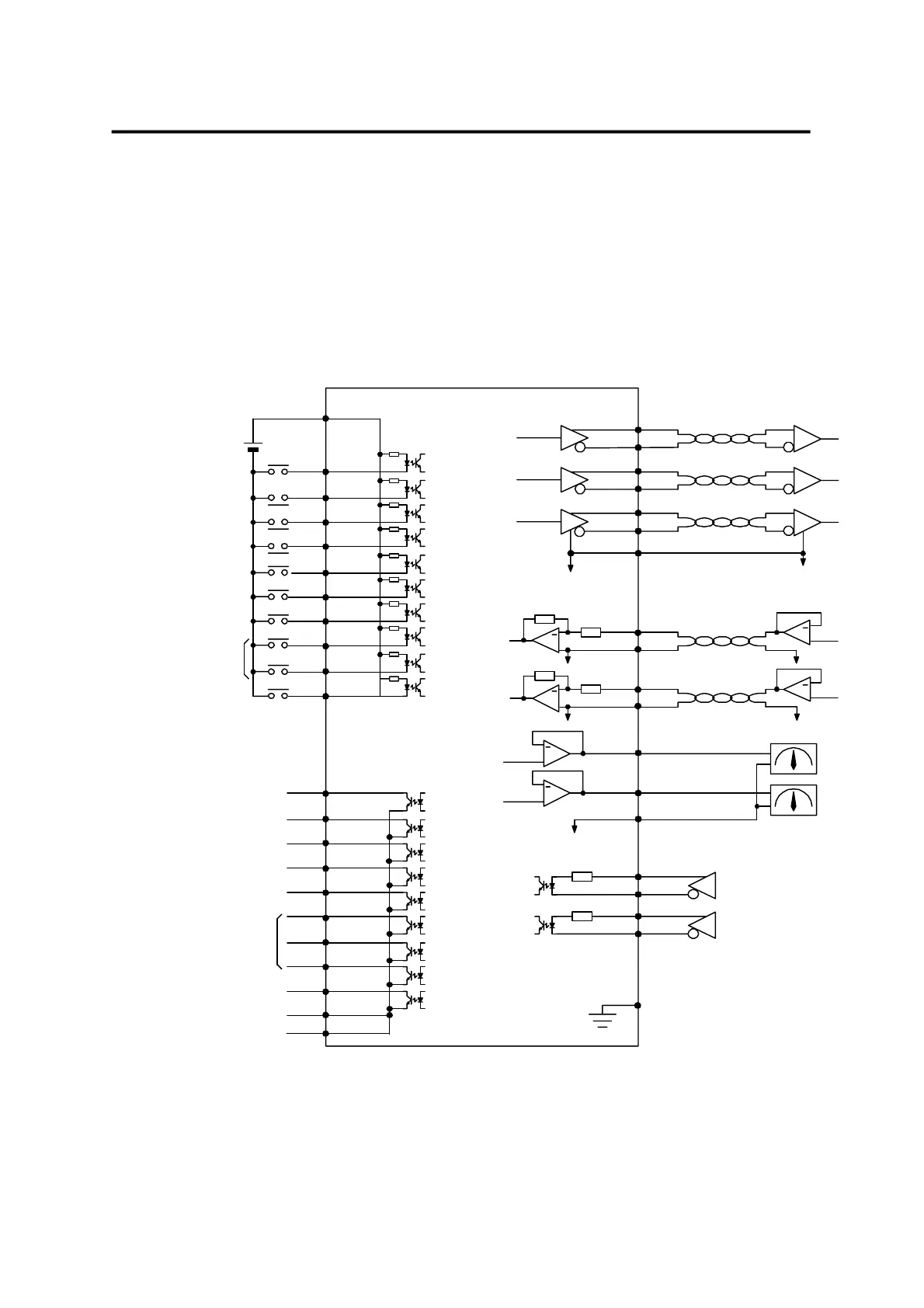

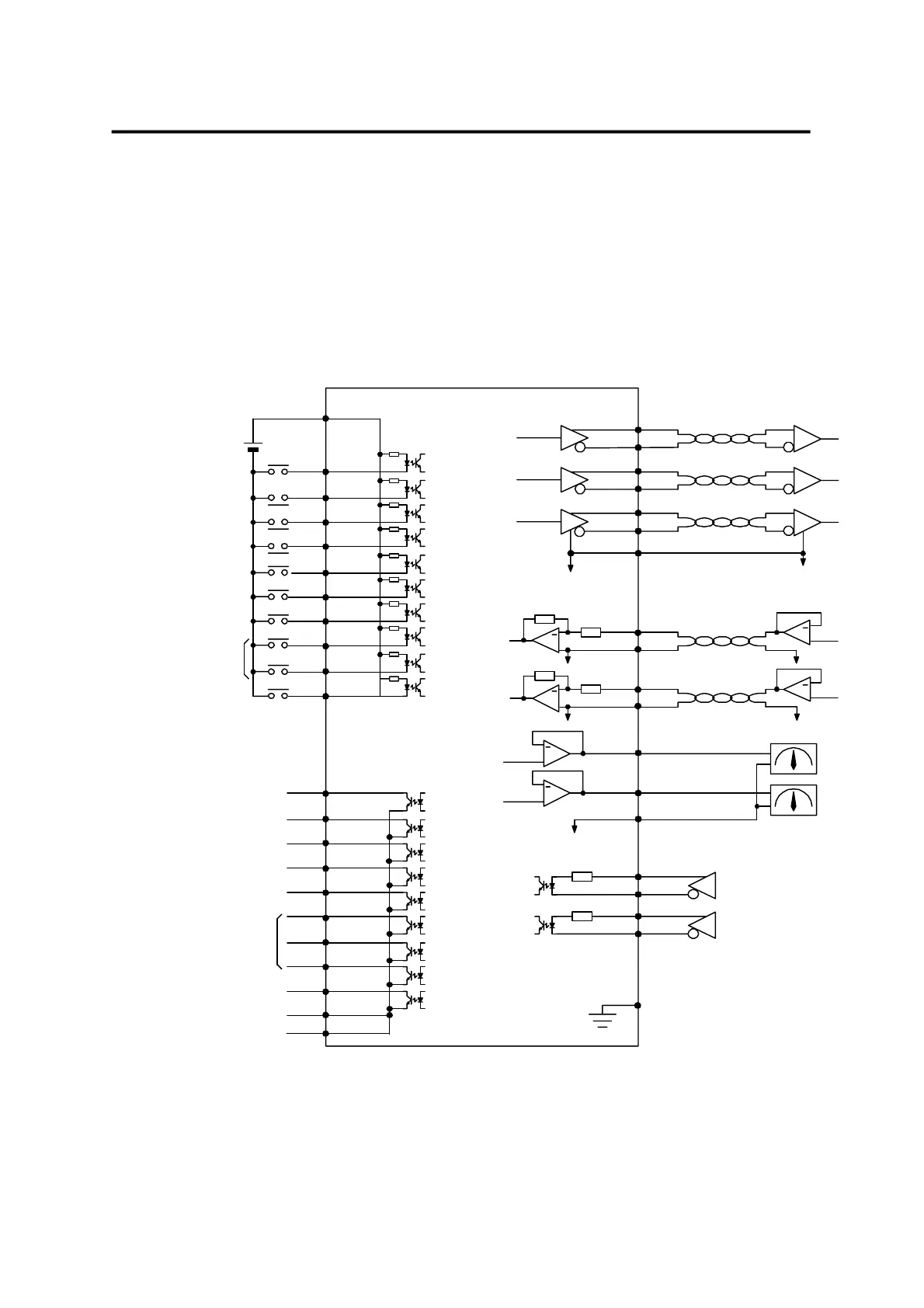

12.2 CN1 Wiring

Make wiring as follows to use FDA5000 as the position/torque control mode.

/PAO

PAO (7)

(32)

/PBO

(6)

(31)

/PZO

PZO (5)

(30)

+

MONIT1

MONIT2

(3)

(2)

SPDIN

(27)

GND

TRQIN (28)

GND

+

+

GND

GND [Note1]

SVONEN(18)

(38)

ALMRST

(41) PI/P

(14) TLIM

(43)

SPD1/

(17)

(15) CCWLIM

(40) CWLIM

(39) ESTOP

+24V

+24VIN(49)

Servo enable

CCW limit

CW limit

Emergency stop

Cumulative pulse clear

[Note3] Select PI/P

[Note3] Analog torque limit

(24) GND24

(25) GND24

A_CODE0

A_CODE1

A_CODE2

(45)

(44)

(19)

ZSPD(47)

ALARM(20)

(22)

(21) RDY

BRAKE(48)

Servo ready

Zero speed

Brake activate

Alarm status

Alarm code

10K

10K

(42) TYPE

TRQOUT(46)

Torque under limit

PBO

-10 ~ +10V

-4 ~ +4V

4.7K

[Note1]

[Note1]

+

+

10K

10K

-10 ~ +10V

[Note1]

+

-4 ~ +4V

F.G

(50)

[Note2]

300

(11)

(10)

(9)

(12)

PPFIN

PFIN

PPRIN

PRIN

300

Alarm reset /

Select position/torque

(On / Off)

/CLR

GEAR1

SPD2/

GEAR2

[Note3] In speed

INPOS

Select speed /

Select electronic gear

Note1 : Select GND terminal from among 1,8,26,33,34 and 36.

Note2 : Use CN1 shield wire to ground the F.G.(Frame Ground) terminal.

Note3 : Available for position mode.

*Note)If used in the

Open Collector System

short-circuit the

PPFIN(11), PPRIN(9)

terminal.

(See section 3.4.3)

Position command pulse input

(Line Drive : SN75174)

Loading...

Loading...