5. Servo operating

4-16

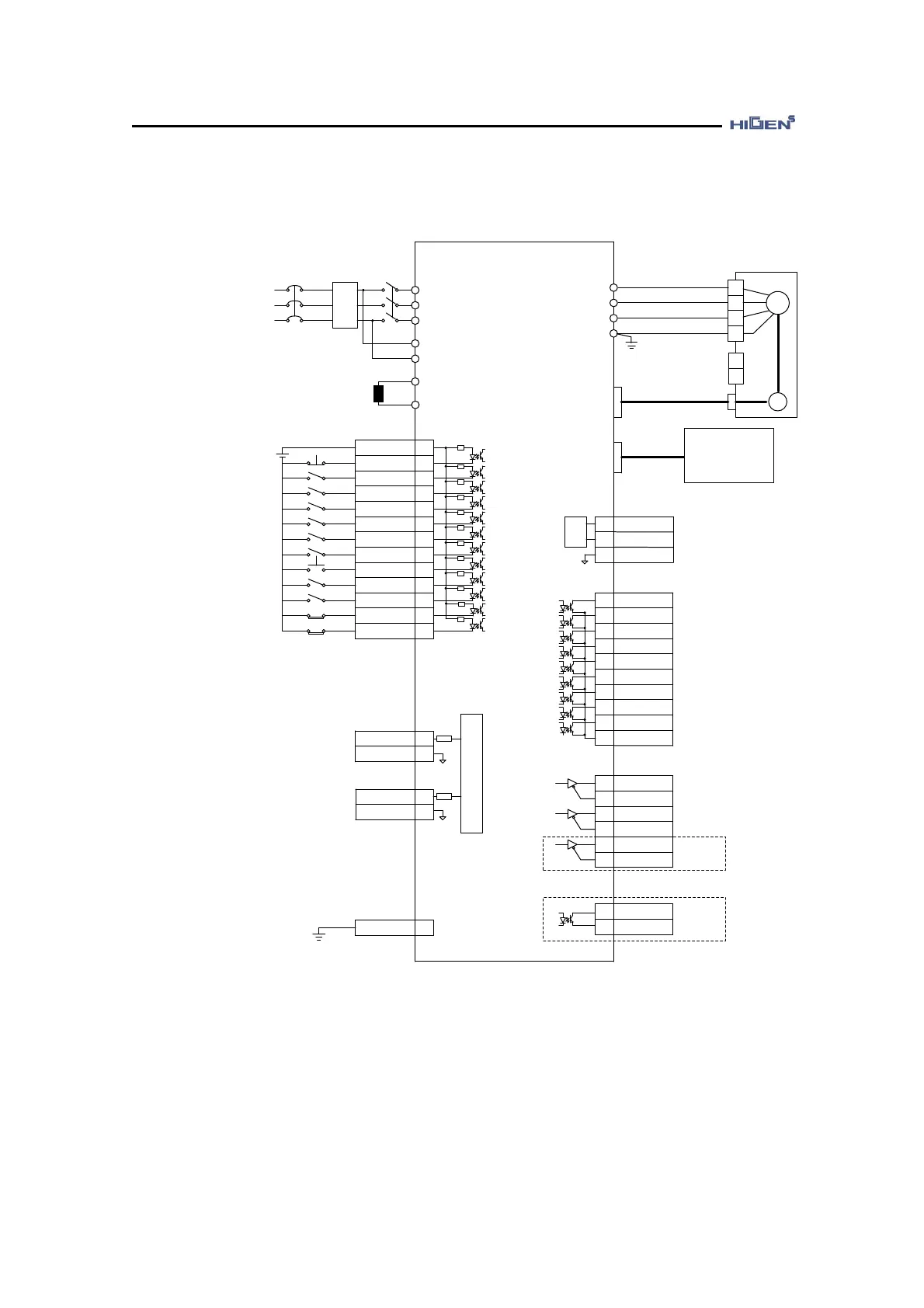

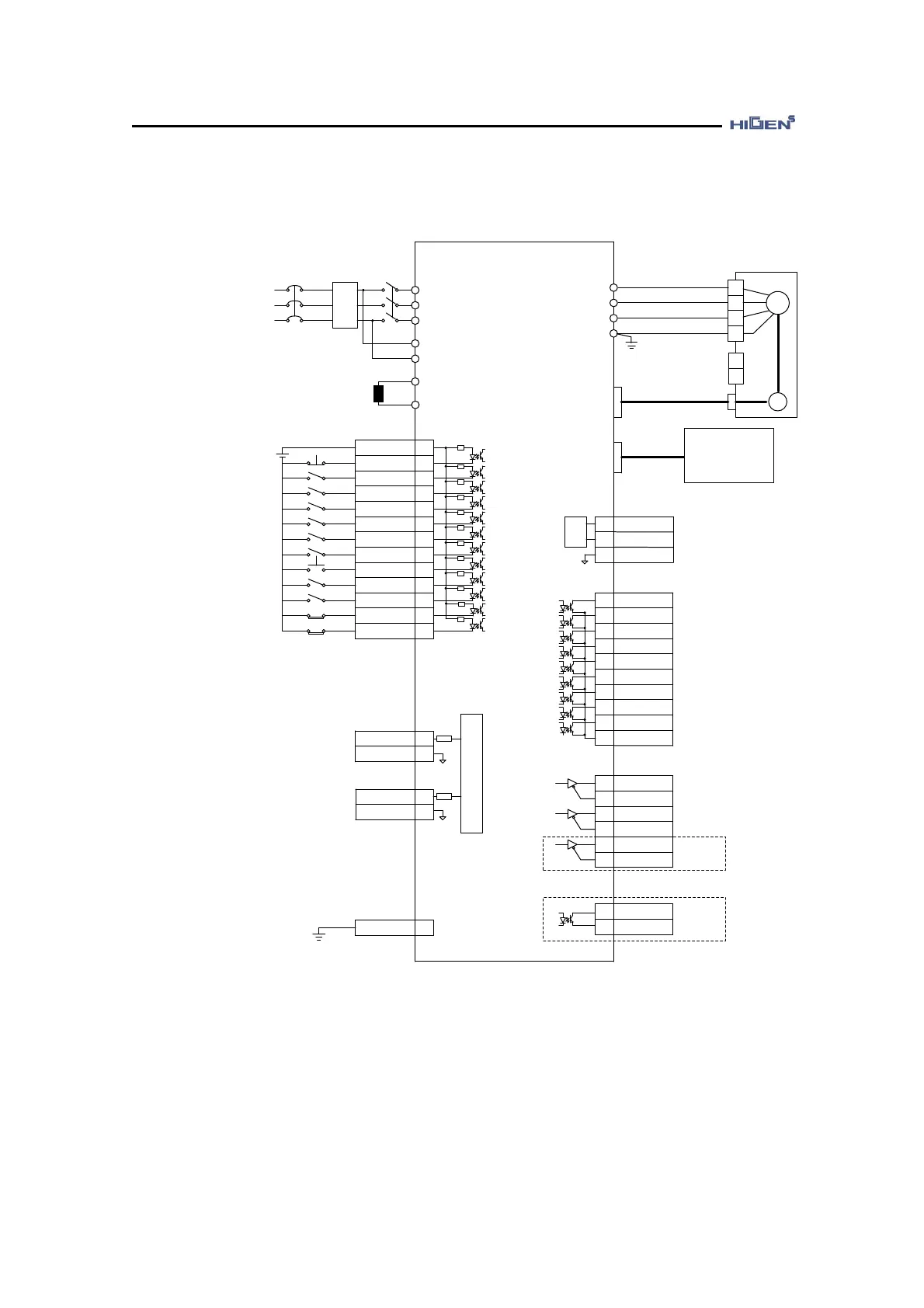

4.3.1. CN1 wiring diagram for torque control servo

Servo Drive

FDA7000

R

S

T

r

t

P

B

CN1

(INPUT)

49

17

16

41

15

40

43

18

42

38

14

13

39

27

28

3.3K

+

-

+24V

U

V

W

FG

SM

+

-

Bake

Input

Voltage

Terminal

U

V

W

FG

PG

CN2

CN3

3

2

47

48

22

19

21

46

20

45

44

7

32

6

31

5

30

CN1

(OUTPUT)

A/D

D/A

NF

NFB MC1

Regenerative

Resistance

*PC Loader(RS232C)

*Network communication

(RS485, RS232C)

(Note1)

(Note2)

50

(Note4)

(Note3)

3.3K

3.3K

3.3K

3.3K

3.3K

3.3K

3.3K

3.3K

3.3K

3.3K

3.3K

LPF

LPF

23

(Note5)

(Note6)

1

33

34

36

24

25

8

26

24

25

+24V

ESTOP

TRQ1

TRQ2

SVONEN

ALMRST

SPDLIM/TLIM

DIR

CWLIM/

NTQLIM

CCWLIM/

PTQLIM

SPDIN

GND

TRQIN

GND

FG

MONIT1

MONIT2

GND

INSPD/INPOS

/INTRQ

BRAKE

RDY

ZTRQ

SPDOUT/

TRQOUT

ALARM

GND24

PAO

/PAO

PBO

/PBO

PZO

/PZO

OPC_ZO

GND24

SPD1/

GEAR1

SPD2/

GEAR2

PCWOUT/

PTQOUT

NCWOUT/

NTQOUT

Input Voltage

FDA7000 Type : AC220V

FDA7000-H0 Type : AC380V

FDA7000-H1 Type : AC440V

50/60Hz

♥The above input and output contact points are shown when setting the torque control mode contact point. (P07-01,P08-

01=25).

(Note1) Be sure to use Noise Filter (NF) to prevent noise from entering the outside.2 :

(Note2) Supply power to the r and t terminals as shown below.

FDA7004-H1 ~ FDA7150-H0 : AC 220V

FDA7020-H0 ~ FDA7750-H0 : AC 380V

FDA7020-H1 ~ FDA7750-H1 : AC 440V

Loading...

Loading...