I English

OPTIONAL ACCESSORIES...sold separately

[1] ExtensionHolderand Stopper(CodeNo.322710)

42) Saw blade 10" (255mm)TCT Saw blade for wood cut (Totalteeth:

60) (CodeNo.976472)

[3) Sawblade10"(255mm)TCTSawbladefor aluminum cut (Totalteeth:

100)(CodeNo.319658)

[4_ Crown molding Vise Ass'y (Code No. 322712) (Include Crown

molding Stopper(L))

[5) Crown molding Stopper(L)(CodeNo. 322713)

[6) Crown molding Stopper(R)(CodeNo. 322714)

NOTE:

Accessoriesaresubjectto changewithout any obligationonthe

partof theHITACHI.

APPLICATIONS

Woodand aluminum sash.

PREPARATION BEFORE OPERATION

Make the following preparations before operating the power tool:

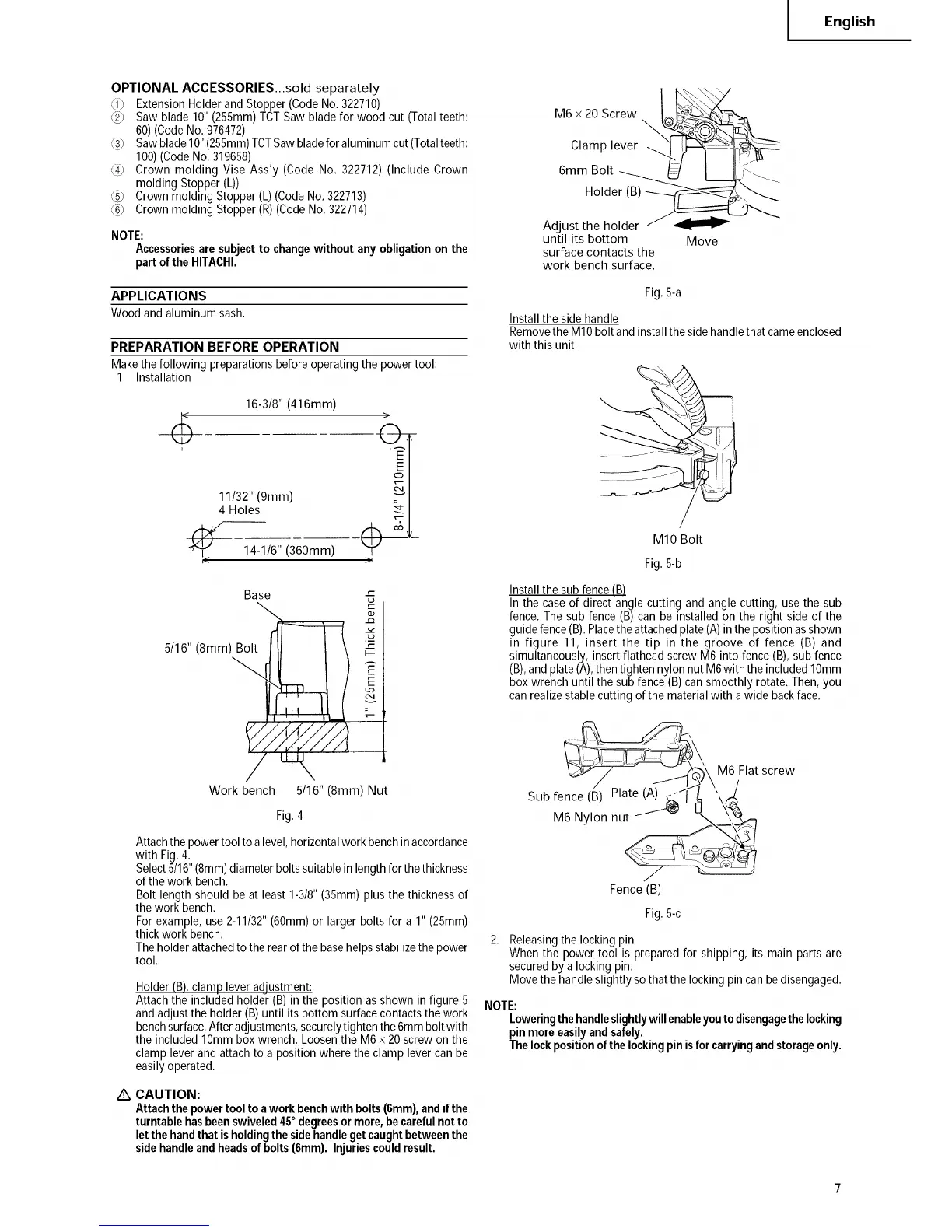

1. Installation

16-3/8" (416mm)

11/32" (9mm)

4 Holes

_ 14-1/6" (360mm)

.)

)1

Base -=

{3

5/16" (8ram) Bol

E

Work bench 5/16" (8ram) Nut

Fig.4

Attach the power tool to a level, horizontal work bench in accordance

with Fig. 4.

Select 5/16" (8mm) diameter bolts suitable in length for the thickness

of the work bench.

Bolt length should be at least 1-3/8" (35mm) plus the thickness of

the work bench.

For example, use 2-11/32" (60ram) or larger bolts for a 1" (25ram)

thick work bench.

The holder attached to the rear of the base helps stabilize the power

tool.

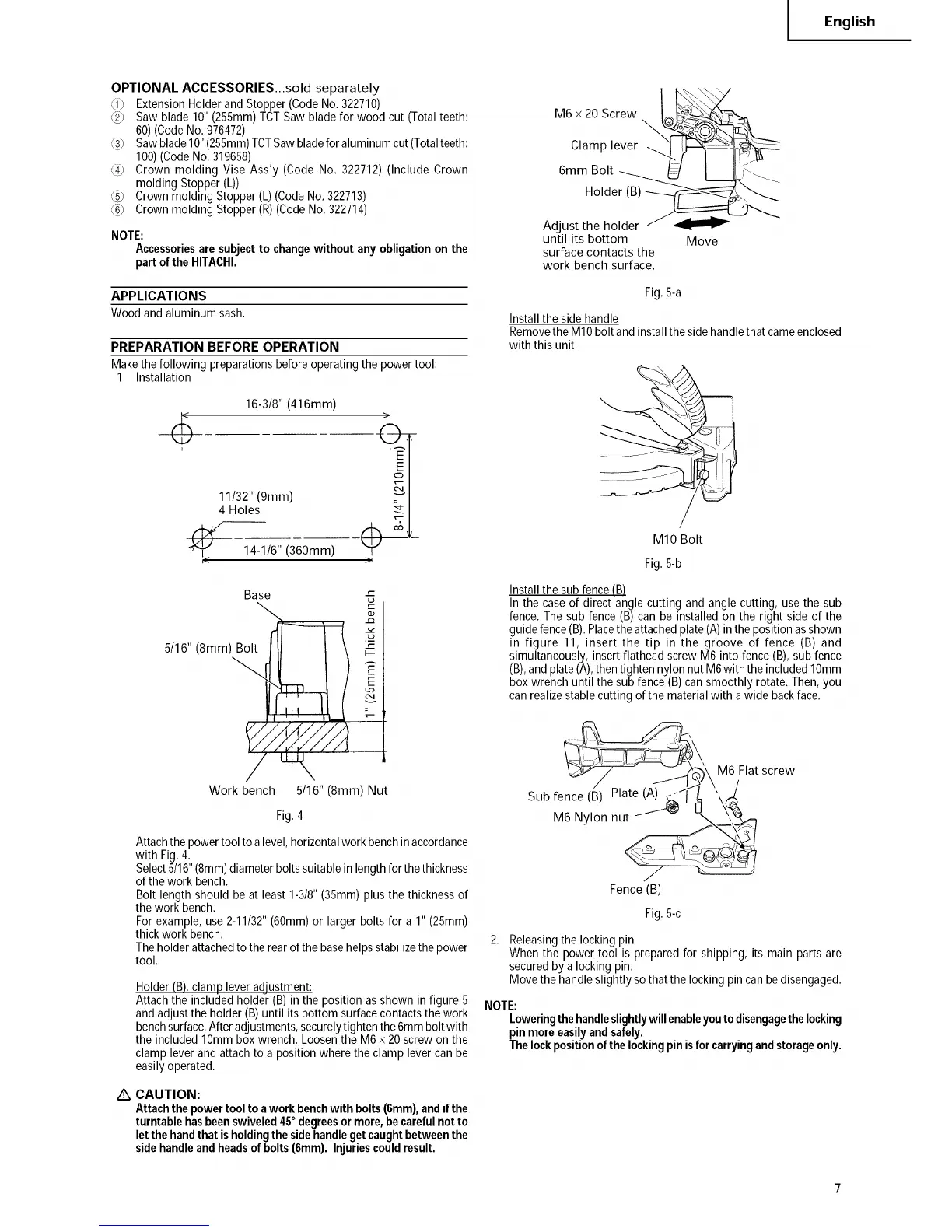

Holder (B),clamp lever adjustment:

Attachthe includedholder (B)in the position as shown in figure 5

and adjustthe holder (B) until its bottom surfacecontactsthe work

benchsurface.Afteradjustments,securelytighten the6mmboltwith

the included 10mmbox wrench. Loosenthe M6 x 20screw on the

clamp lever and attachto a position where the clamp lever canbe

easilyoperated.

/_ CAUTION:

Attachthepowertooltoa workbenchwith bolts(6mm),andifthe

turntablehasbeenswiveled45° degreesormore,becarefulnotto

letthehandthatisholdingthesidehandlegetcaughtbetweenthe

sidehandleandheadsof bolts(6mm). InJuriescouldresult.

M6x2OScrew _ ___

Adjust tiilii[__

until its bottom Move

surface contacts the

work bench surface.

Fig.5-a

Install the side handle

Remove the MIO bolt and install the side handle that came enclosed

with this unit.

MIO Bolt

Fig.5-b

Installthe sub fence(B)

In the caseof direct angle cutting and angle cutting, use the sub

fence.The sub fence (B) can be installed on the right side of the

guide fence(B).Placetheattachedplate (A)in theposition asshown

in figure 11, insert the tip in the groove of fence (B) and

simultaneously, insert flathead screwM6 into fence(B),subfence

(B),and plate(A),thentighten nylon nutM6with the included10mm

box wrench until the subfence (B) cansmoothly rotate.Then, you

canrealizestablecutting of the materialwith a wide backface.

_\M6 Flat screw

Sub fence (_ Plate (A_J_'\'\ ,.-_

M6 Nylon nut_,j_

Fence (B)

Fig.5-c

Releasingthe locking pin

Whenthe powertool is preparedfor shipping, its main parts are

securedby a lockingpin.

Move the handleslightly so that the lockingpin canbedisengaged.

NOTE:

Loweringthehandleslightlywillenableyoutodisengagethelocking

pinmoreeasilyandsafely.

Thelockpositionofthelockingpinisfor carryingandstorageonly.

Loading...

Loading...