English I

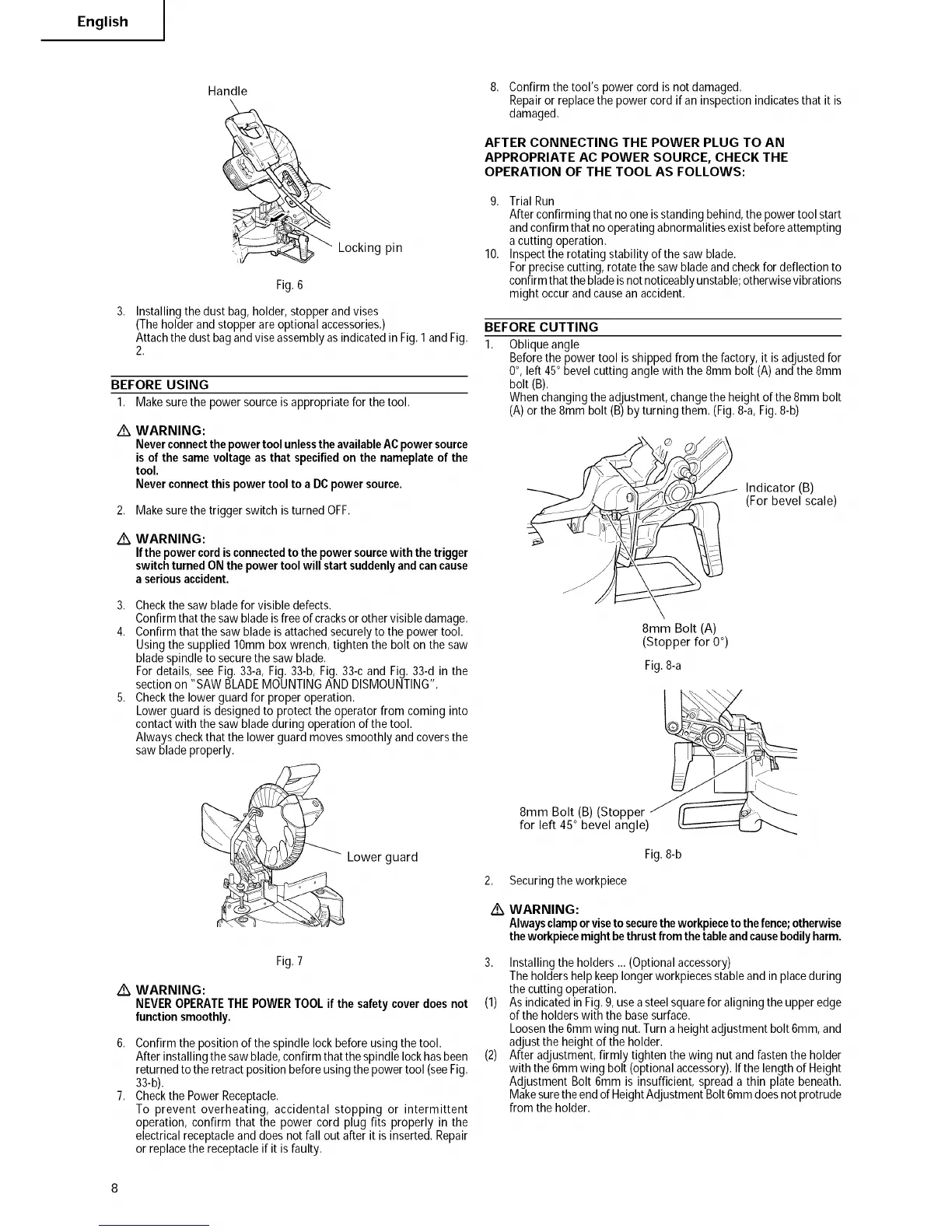

Handle

9

Locking pin

Fig. 6

Installing the dust bag, holder,stopper and vises

(Theholder and stopper are optional accessories.)

Attachthe dust bagandviseassemblyas indicatedin Fig.1and Fig.

2.

BEFORE USING

1. Makesure the power source isappropriatefor the tool.

/k

WARNING:

NeverconnectthepowertoolunlesstheavailableACpowersource

isof the samevoltageasthat specifiedon the nameplateof the

tool.

Neverconnectthispowertoolto a DCpowersource.

2. Makesure the trigger switch isturned OFF.

/k

WARNING:

Ifthepowercordisconnectedto thepowersourcewith thetrigger

switchturnedONthepowertool willstartsuddenlyandcancause

a seriousaccident.

3. Checkthe saw bladefor visible defects.

Confirmthat thesaw bladeisfreeof cracksor othervisible damage.

4. Confirmthat the saw blade is attachedsecurelyto the powertool.

Using the supplied 10mm boxwrench,tighten the bolt on the saw

blade spindleto securethe saw blade.

For details, see Fig. 33-a, Fig. 33-b, Fig. 33-c and Fig. 33-d in the

sectionon "SAW BLADEMOUNTINGANDDISMOUNTING".

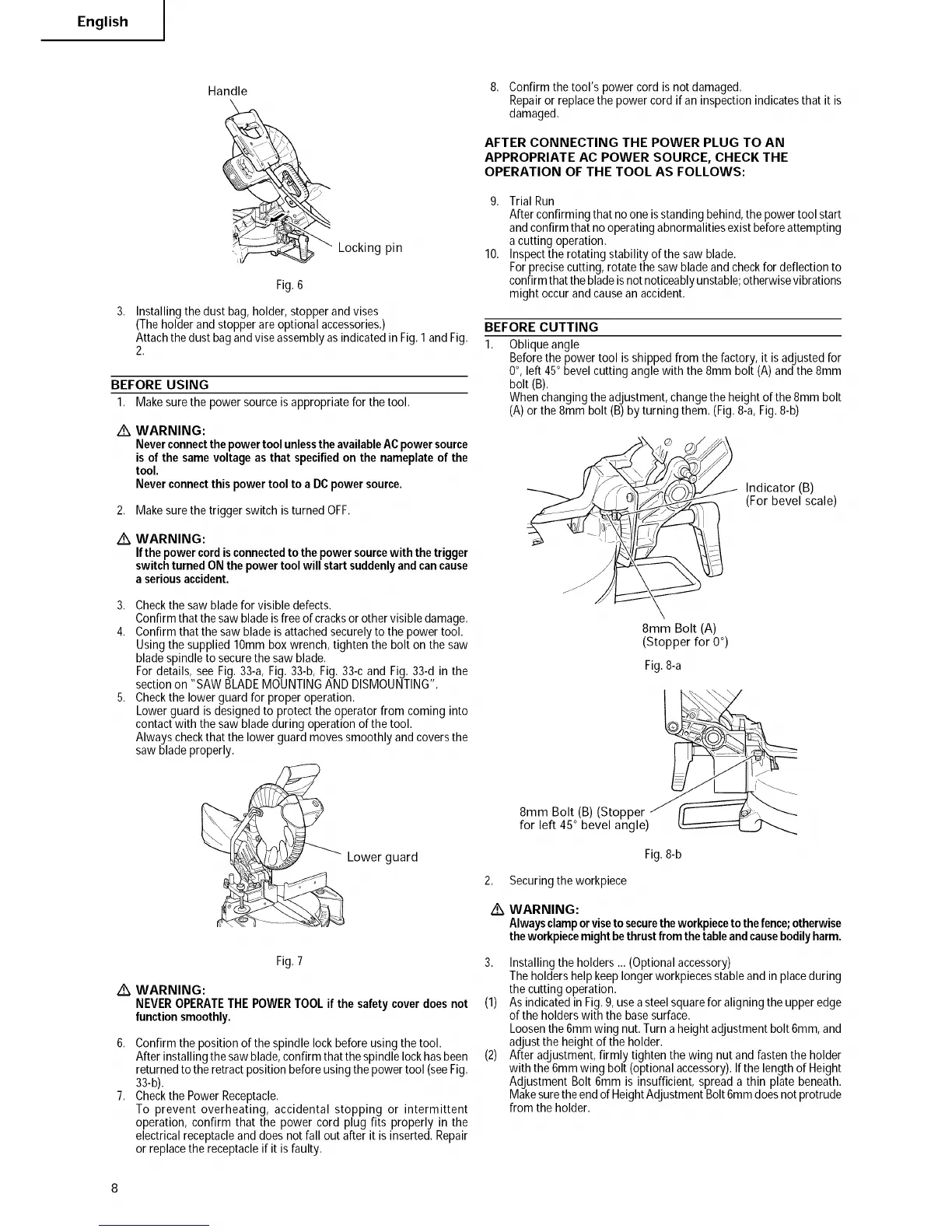

5. Checkthe lowerguard for proper operation.

Lowerguard is designedto protect the operator from coming into

contactwith the saw bladeduring operation of the tool.

Always checkthat the lower guardmovessmoothly and coversthe

saw blade properly.

Lower guard

./k

Fig.7

WARNING:

NEVEROPERATETHEPOWERTOOLifthe safetycoverdoesnot

function smoothly.

6. Confirmthe position of the spindle lockbefore using thetool.

After installingthe sawblade,confirm that thespindle lockhasbeen

returnedto the retractposition before usingthe powertool (seeFig.

33-b).

7. Checkthe PowerReceptacle.

To prevent overheating, accidental stopping or intermittent

operation, confirm that the power cord plug fits properly in the

electricalreceptacleand does notfall out after it is inserted. Repair

or replacethe receptacleif it isfaulty.

8. Confirmthe tool's powercord is not damaged.

Repairor replacethe powercord if aninspection indicatesthat it is

damaged.

AFTER CONNECTING THE POWER PLUG TO AN

APPROPRIATE AC POWER SOURCE, CHECK THE

OPERATION OF THE TOOL AS FOLLOWS:

9. Trial Run

Afterconfirming that noone isstanding behind,the power tool start

andconfirm that nooperatingabnormalitiesexist beforeattempting

a cutting operation.

10. Inspectthe rotating stability of the saw blade.

Forprecisecutting, rotatethe saw bladeand checkfor deflection to

confirmthatthebladeis notnoticeablyunstable;otherwisevibrations

might occur and causean accident.

BEFORE CUTTING

1. Oblique angle

Beforethe power tool is shippedfrom the factory, it isadjustedfor

0°, left 45° bevel cuttingangle with the 8mm bolt (A) and the 8mm

bolt (B).

Whenchangingthe adjustment,changethe heightof the 8ram bolt

(A)or the 8mm bolt (B)by turning them. (Fig.8-a, Fig.8-b)

Indicator (B)

(For bevel scale)

8mm Bolt (A)

(Stopper for 0°)

Fig.8-a

2,

/k

8mm Bolt (B) (Stopper

for left 45° bevel angle)

Fig.8-b

Securingthe workpiece

WARNING:

Alwaysclamporvisetosecurethe workpieceto thefence;otherwise

theworkpiecemightbethrustfromthetableandcausebodilyharm.

3. Installing the holders ... (Optionalaccessory)

Theholdershelpkeeplonger workpiecesstableand in placeduring

the cutting operation.

(1) As indicatedin Fig.9,usea steelsquarefor aligningtheupper edge

of the holderswith the basesurface.

Loosenthe 6ramwing nut.Turn a heightadjustmentbolt 6ram,and

adjustthe heightof the holder.

(2) After adjustment,firmly tighten the wing nut and fasten the holder

with the 6ramwing bolt (optionalaccessory).If the lengthof Height

Adjustment Bolt 6mm is insufficient,spread a thin plate beneath.

Makesurethe endofHeightAdjustmentBolt6ramdoesnot protrude

from the holder.

Loading...

Loading...