I English

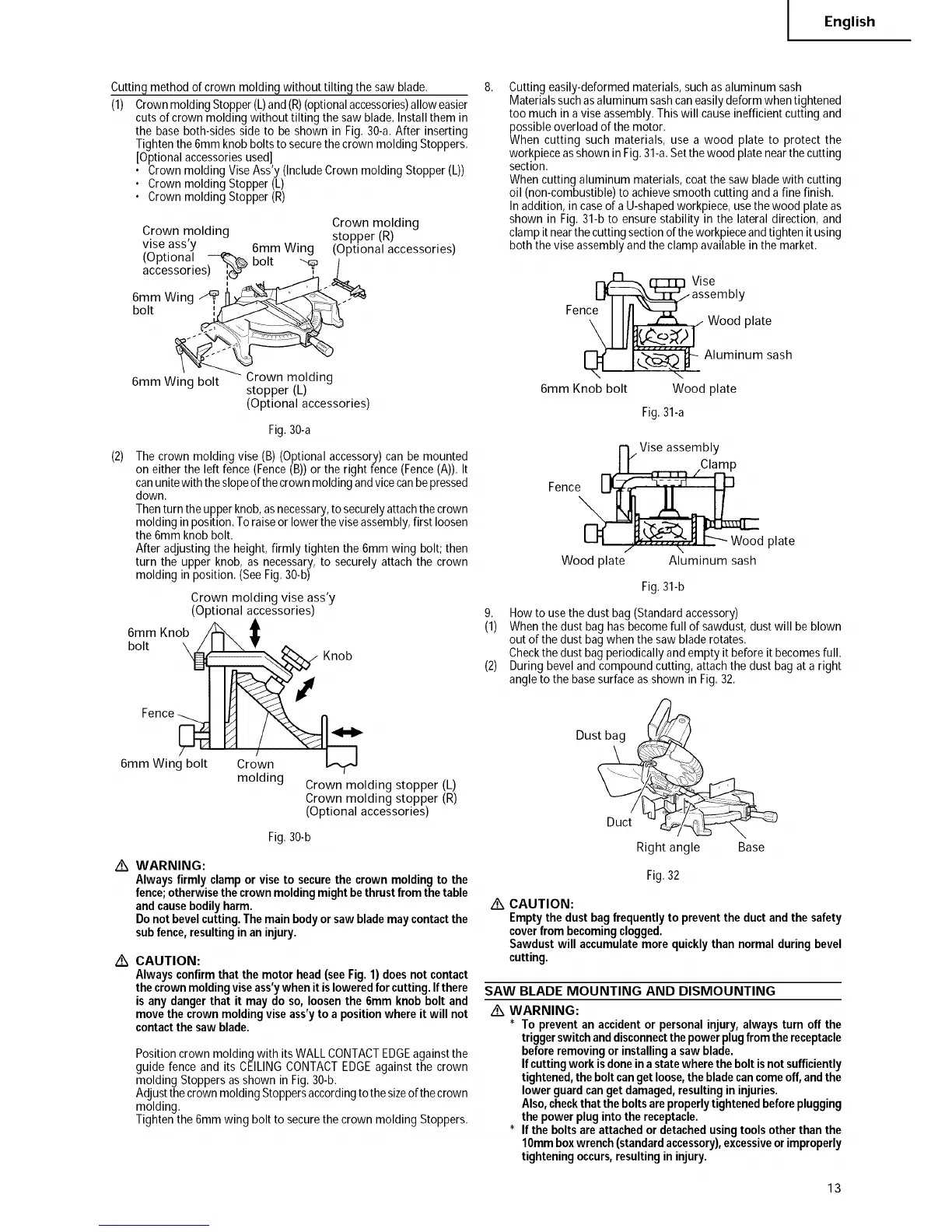

Cutting methodof crown molding without tilting the saw blade.

(1) Crownmolding Stopper(L)and(R)(optionalaccessories)alloweasier

cutsof crown molding without tilting the saw blade.Installthem in

the baseboth-sides sideto be shown in Fig. 30-a.After inserting

Tightenthe 6ramknob boltstosecurethe crown molding Stoppers.

[Optionalaccessoriesused]

• Crown molding ViseAss'y (IncludeCrown molding Stopper(L))

• Crown molding Stopper (L)

• Crown molding Stopper (R)

Crown molding

Crown molding stopper (R)

vise ass'y 6ram Wing (Optional accessories)

(Optional _ bolt _ i

accessories) [_ T I

6mm Wing _ __

bolt

m Wi° o,t :o2o X,o,di°

(Optional accessories)

(2)

Fig.30-a

Thecrown molding vise (B) (Optional accessory)can be mounted

on either the left fence (Fence(B))or the right fence (Fence(A)). It

canunitewith theslopeof thecrownmoldingandvicecanbepressed

down.

Thenturn theupperknob,as necessary,to securelyattachthe crown

molding in position.To raiseor lowertheviseassembly,first loosen

the 6ramknob bolt.

After adjusting the height,firmly tighten the 6mmwing bolt; then

turn the upper knob, as necessary,to securely attach the crown

molding in position. (SeeFig.30-b)

Crown molding vise ass'y

(Optional accessories)

6mm Knob

bolt \

Knob

6mm Wing bolt

Crown

molding

Crown molding stopper (L)

Crown molding stopper (R)

(Optional accessories)

Fig.30-b

Ak WARNING:

Always firmly clamp or vise to secure the crown molding to the

fence; otherwise the crown molding might be thrust from the table

and cause bodily harm.

Do not bevel cutting. The main body or saw blade may contact the

sub fence, resulting in an injury.

Ak CAUTION:

Always confirm that the motor head (see Fig. 1) does not contact

the crown molding vise ass'ywhen it islowered for cutting. If there

is any danger that it may do so, loosen the 6mm knob bolt and

move the crown molding vise ass'y to a position where it will not

contact the saw blade.

Positioncrown moldingwith its WALLCONTACTEDGEagainstthe

guide fence and its CEILINGCONTACTEDGEagainst the crown

molding Stoppersas shown in Fig. 30-b.

AdjustthecrownmoldingStoppersaccordingto thesizeof thecrown

molding.

Tightenthe 6ramwing bolt to securethe crown molding Stoppers.

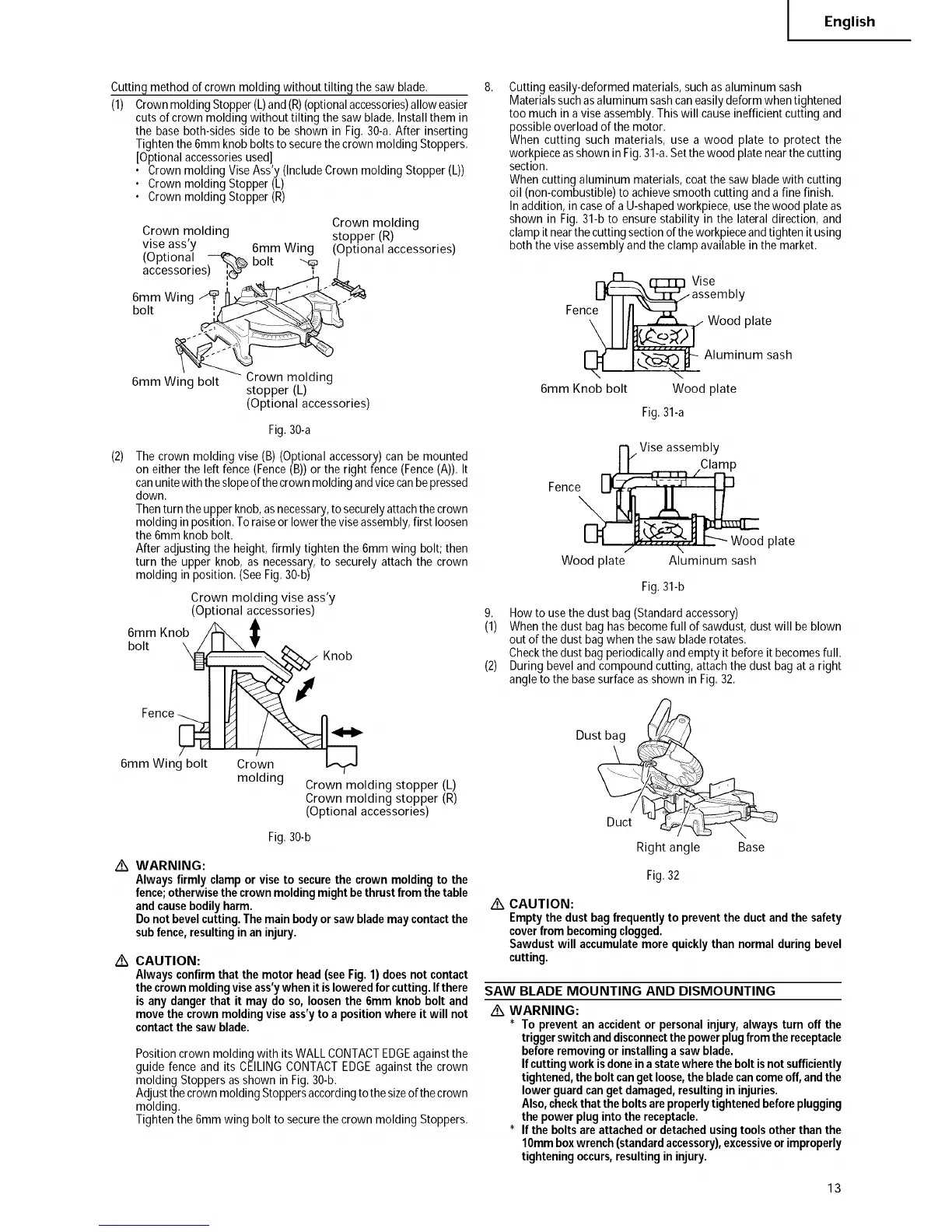

Cutting easily-deformedmaterials, suchasaluminum sash

Materialssuchasaluminum sashcaneasilydeformwhentightened

too much in a viseassembly.Thiswill causeinefficientcutting and

possibleoverload of the motor.

When cutting such materials, use a wood plate to protect the

workpieceas shownin Fig.31-a.Setthe wood platenearthecutting

section.

Whencutting aluminum materials,coat the saw bladewith cutting

oil (non-combustible)to achievesmooth cutting and a fine finish.

Inaddition, in caseof a U-shapedworkpiece,usethewood plateas

shown in Fig. 31-bto ensure stability in the lateraldirection, and

clampit nearthe cuttingsectionof theworkpieceandtighten itusing

both the vise assemblyand the clamp available in the market.

_ Vise

IJi]-r-:_ assembly

Fence I II1

\ III!, ./'-N ,!" Wood plate

__ Aluminum sash

6mm Knob bolt Wood plate

Fig.31-a

i7/Vise assembly

I! Clamp

Fence_

L..rl /-";.."/Y...."_.11F'-'_ Wood

Wood plate Aluminum sash

plate

Fig.31-b

9. Howto usethe dust bag (Standardaccessory)

(1) Whenthe dust bag hasbecomefull of sawdust,dust will be blown

out of the dust bagwhen the saw bladerotates.

Checkthe dust bagperiodicallyand empty it beforeit becomesfull.

(2) During beveland compound cutting, attachthe dust bag at a right

angle to the basesurfaceas shown in Fig. 32.

Dust bag _,

Duct

Right angle

Base

Fig.32

Ak CAUTION:

Empty the dust bag frequently to prevent the duct and the safety

cover from becoming clogged.

Sawdust will accumulate more quickly than normal during bevel

cutting.

SAW BLADE MOUNTING AND DISMOUNTING

/k WARNING:

* To prevent an accident or personal injury, always turn off the

trigger switch and disconnect the power plug from the receptacle

before removing or installing a saw blade.

Ifcutting work is done ina state where the bolt is not sufficiently

tightened, the bolt can get loose,the blade can come off, and the

lower guard can get damaged, resulting in injuries.

Also, checkthat the bolts are properly tightened before plugging

the power plug into the receptacle.

* If the bolts are attached or detached using tools other than the

10mm box wrench (standard accessory),excessive or improperly

tightening occurs, resulting in injury.

13

Loading...

Loading...