106

General Maintenance

4.7 Dirt Shield Replacement

The dirt shield should be inspected daily to ensure

it is tightened properly and that the felt seal is in

good condition.

Use the following procedure to replace a

damaged or worn felt seal:

1. Make sure the waterblasting system is shut-

down and the truck is in the service position.

2. Hold the thru-shaft so it won’t turn with a 3/4”

(19 mm) wrench inserted in the slot at the

base of the thru-shaft motor.

3. Turn the spray bar counterclockwise by hand

until it is free of the shaft.

4. Remove brass button.

5. Use a stainless steel wire brush to clean the

dirt from the thru-shaft threads.

6. While still holding the thru-shaft with the

wrench, remove the dirt shield by turning it

counterclockwise.

7. Remove the felt seal. Then clean the dirt shield

and shroud.

8. Place a new felt seal on the dirt shield and

apply a light coating of anti-sieze to the thru-

shaft threads.

9. Hold the thru-shaft with the 3/4” (19 mm)

wrench, install the new dirt shield and hand

tighten.

NOTICE:

ONLY HAND TIGHTEN THE DIRT SHIELD. NEVER USE TOOLS

TO TIGHTEN THE DIRT SHIELD. IF THE DIRT SHIELD IS

TIGHTENED MORE THAN HAND TIGHT IT WILL CAUSE THE

SPRAY BAR TO ROTATE SLOWLY OR NOT ROTATE AT ALL.

10. Activate the charge water system and purge

the blast head at low pressure to remove de-

bris that could clog the nozzles.

11. Shutdown the waterblasting system and return

the truck to the service position.

12. Install a new brass button seal, hold the thru-

shaft with the wrench and reinstall the spray

bar.

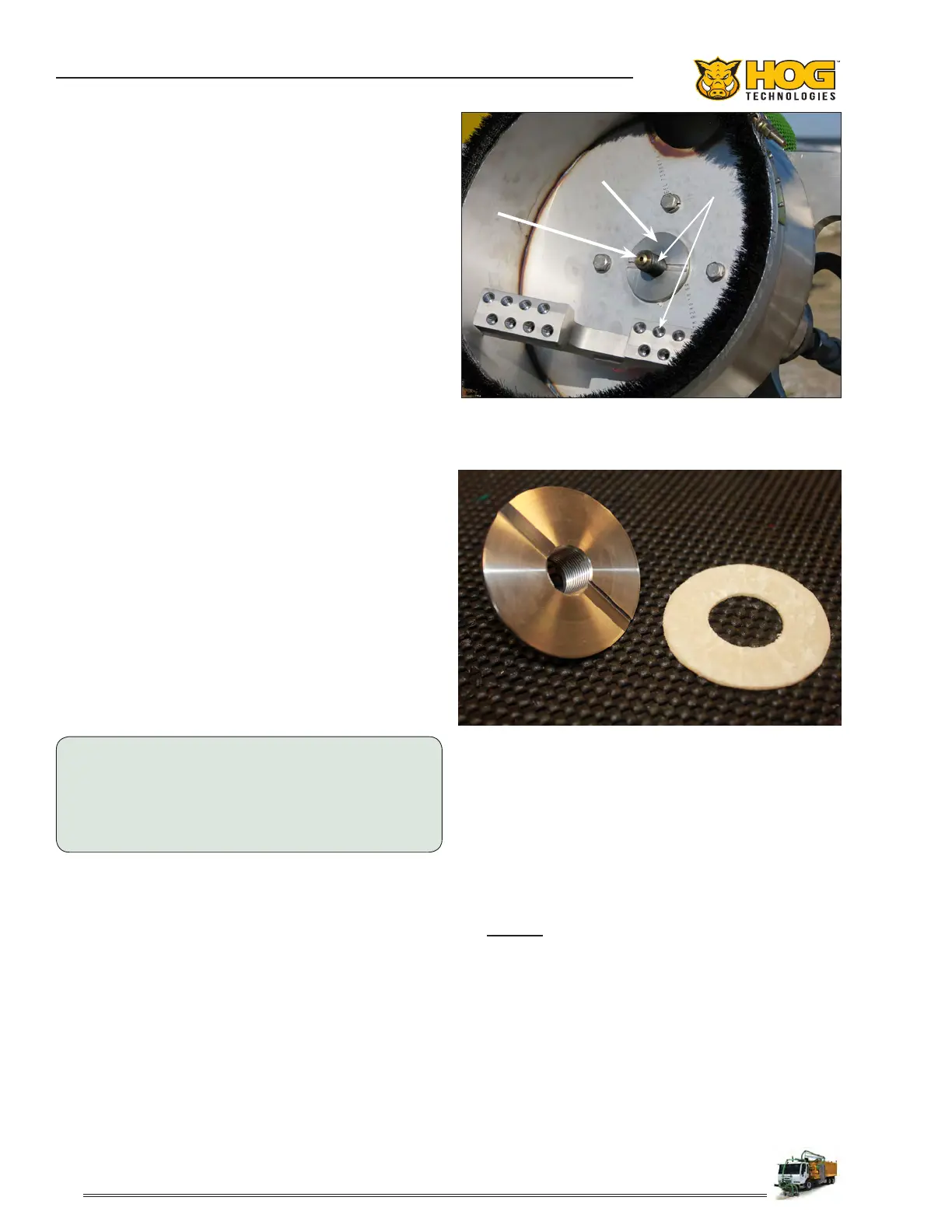

Dirt Shield

Button Seal

Apply Anti-Seize

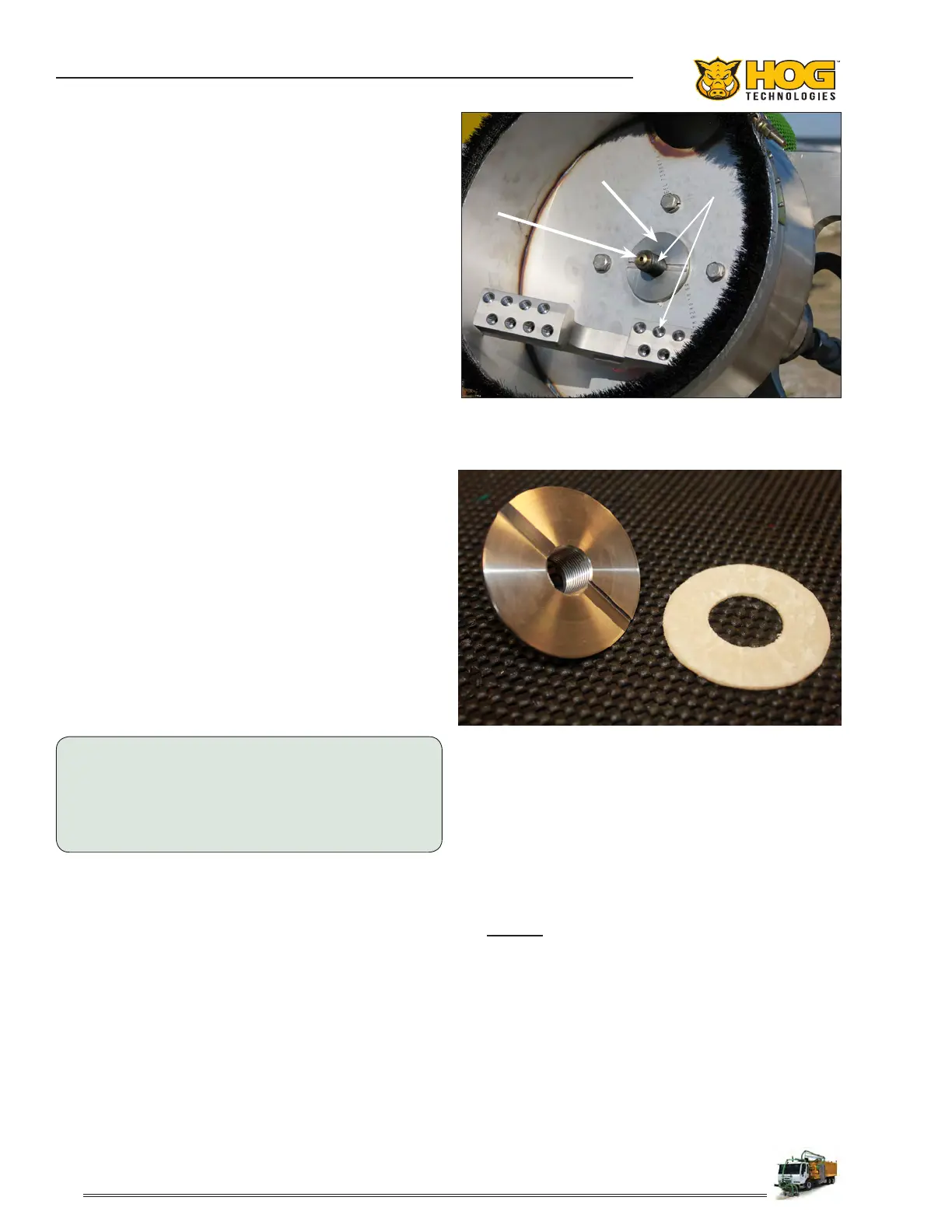

Brass Dirt Shield & Felt Seal

Typical Dirt Shield Installation

13. Tighten the spray bar by turning it clockwise

slowly until it stops. Then seat the seal by

turning the spray bar another 15%. Make sure

you remove the wrench when the installation

is complete.

14. Install the spray bar protector.

Loading...

Loading...