138

Scheduled Maintenance

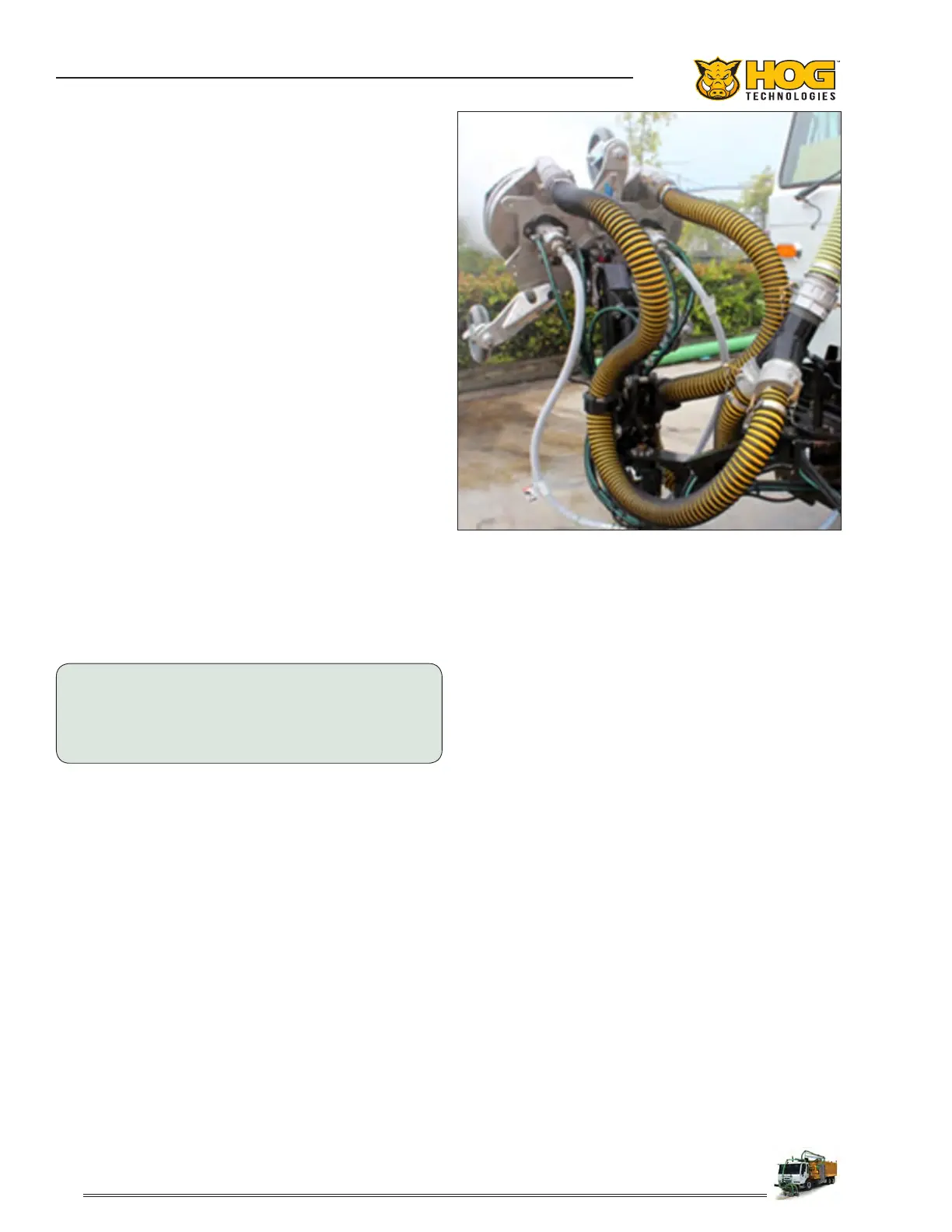

5.14 Vacuum Hose Replacement

& Rotation Procedure

Debris buildup, kinks, clogs or leaks in the system

will cause a reduction in airow at the blasting

heads, reducing the eciency of operation or

causing operations to stop completely. Debris

buildup inside the hoses can be removed by pe-

riodically tapping the outside walls with a dead

blow hammer while the system is operating at

maximum vacuum. This will ex the hose walls and

cause built up debris to break o and be sucked

into the debris tank.

The internal walls of vacuum hoses develop wear

points caused from the high velocity of abrasive

debris traveling inside the hoses. The wear points

are most prevalent in the outside radius of tight

bends near the blasting heads and where the de-

bris hose rises above the truck cab.

The life of the hoses in these areas can be ex-

tended by rotating the hoses 120

0

every 200

hours. Vacuum hoses should be inspected daily

and replaced as needed.

Make sure the waterblasting system is shutdown

with the truck in the service position before rotat-

ing or replacing vacuum hoses.

NOTICE:

DAMAGED VACUUM HOSES CAN BE REPAIRED USING DUCT

TAPE AS A TEMPORARY SOLUTION TO EXTEND THE LIFE

OF THE VACUUM HOSE.

Vacuum Hose Replacement

1. Release the cam locks at the hose connection

ttings.

2. Remove the old vacuum hose assembly.

3. If the cam lock ttings are in good condition

and can be reused, cut the old hose o of the

ttings. Then install the ttings in the new

vacuum hose.

4. Connect the new vacuum hose assembly and

close the cam locks.

Vacuum Hose Rotation

1. Mark the position of the hose, then release the

cam locks at the hose ttings.

2. Using the marks as a reference, rotate the

hose 120 degrees.

3. Secure the hose in the new position with the

cam locks.

Blast Head Vacuum Hoses

Loading...

Loading...