86

Operation

9. Rotate the Head Rotation speed dial clockwise

to test the spray bar rotation and set the de-

sired rotation speed.

10. With the pressure set and the spray bar and

nozzles working properly, press the STOP

switch on the joystick console so no pressure

is supplied to the blastheads and lower the

blast heads to the pavement. Press the Float

switch to engage Float Mode for the Hog Arm.

11. The truck is now ready to begin waterblasting

operations.

ANY CONTACT WITH HIGH PRESSURE WATER IS VERY

DANGEROUS AND CAN BE FATAL! USE EXTREME CAUTION

WHILE RAISING OR MOVING HOG HEAD & ARM ASSEMBLY

WHEN HIGH PRESSURE IS ENGAGED.

3.4 Waterblasting Operations

Overview

Before you start the job, you should evaluate the

pavement and the material to be removed. Choose

the appropriate spray bars and/or nozzles best

suited for the job. You should also consider the

desired or expected prole of the blasted surface

in your selection. There are many variables that

aect blasting eciency, productivity and the

prole of the blasted surface. As the operator

becomes more experienced, the selection process

becomes more rened and easier.

Generally, large, high volume (.015 - .017) nozzles

are the most aggressive and provide faster re-

sults, but provide greater potential for damage

and a course prole. High volume nozzles should

be used only on strong pavement (concrete or

newer pavement). Small, low volume (.007 -

.011) nozzles are less aggressive and will provide

somewhat slower results but provide less potential

for damage and a smoother prole. Low volume

nozzles are well suited for weak pavement (older

or damaged pavement). Low volume nozzles are

typically a better choice for inexperienced opera-

tors on any surface.

Hog Technologies oers an on-site training pro-

gram that dramatically reduces the learning curve

and increases productivity. If you are new to

Waterblasting, we highly recommend that you

consider this factory training for your operators.

You can also contact Hog Technologies Customer

Service department for assistance in choosing

spray bars and nozzles or more information re-

garding the factory training program.

THE PAVEMENT WILL BE DAMAGED IMMEDIATELY IF HIGH

PRESSURE BLASTING IS ACTIVATED WITHOUT THE HOG

HEAD MOVING. ALWAYS MAKE SURE TRUCK IS MOVING

BEFORE SUPPLYING HIGH PRESSURE TO THE BLAST

HEADS.

Before Blasting Operations Begin

Evaluate the Pavement and Select a Spray Bar

• Strong pavement withstands high aggression

spray bars. This is generally concrete or new

asphalt.

• Cracked pavement is weak and will require

less aggressive spray bars.

• Brittle pavement is a challenge and will require

less aggressive spray bars and reduced pres-

sure.

• Consider spray bar width. Choose a spray bar

2” wider than the line being removed to pro-

vide steering tolerance plus slight over spray

to reduce the potential for missed areas and

need to back up and re-do sections.

• Pre-clean the work area with a power broom

if necessary before blasting.

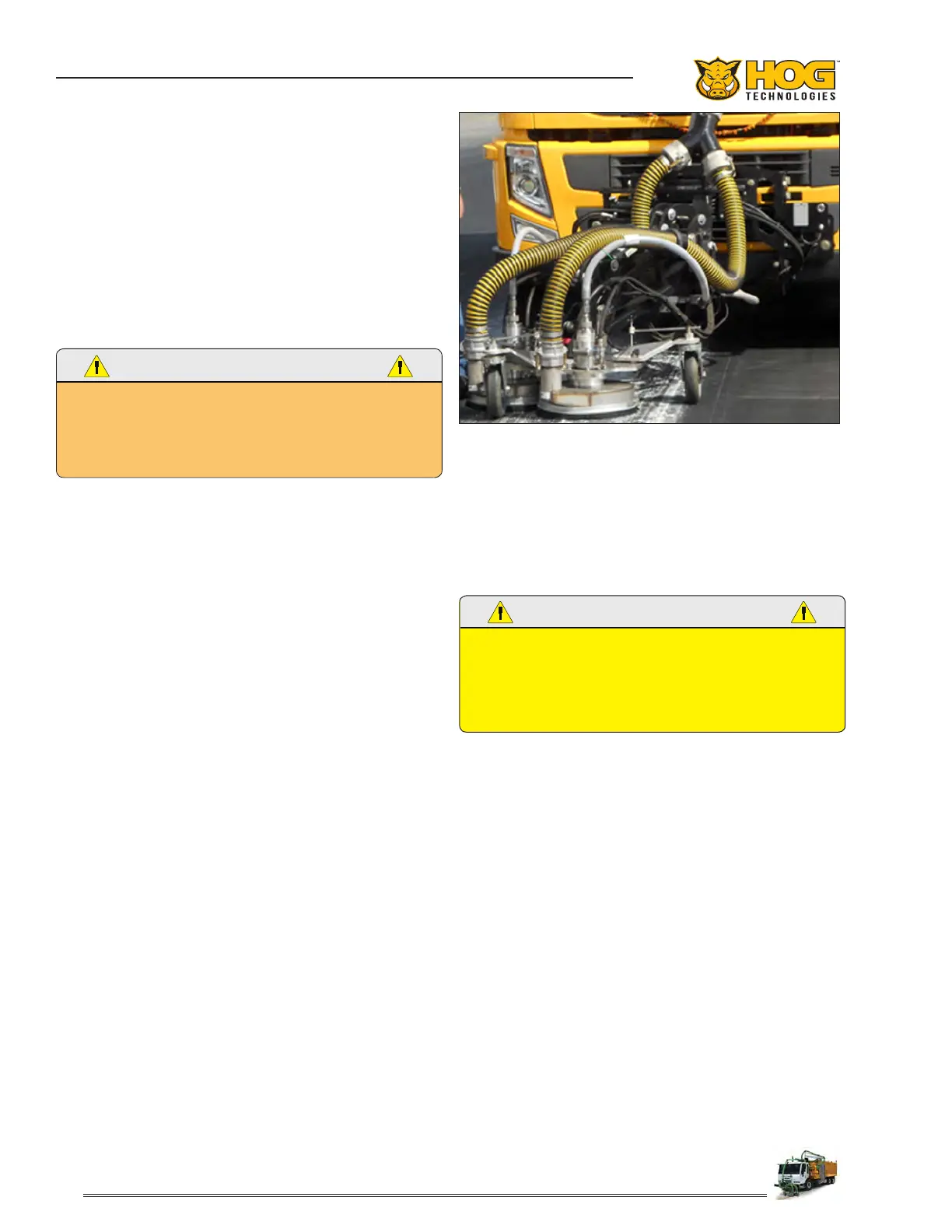

Stripe Hog In Operation

Loading...

Loading...