116

Scheduled Maintenance

5.4 Ultra High Pressure Pump

Scheduled Maintenance

The 40K UHP pump operates at very high pres-

sure and has specic lubrication and maintenance

requirements. Refer to the Maintenance Matrix

in this section and the pump manufacturer’s op-

erating and maintenance manual for lubrication

specications and maintenance schedules.

Daily Inspection and Maintenance

• Check the crankcase lubricating oil level.

NOTICE:

THE PROCEDURE FOR CHECKING THE CRANKCASE OIL

LEVEL IS DIFFERENT FOR WHEN THE PUMP HAS NOT BEEN

OPERATING FOR 5 OR MORE HOURS AND WHILE THE PUMP

IS IN OPERATION. REFER TO UHP PUMP CRANKCASE OIL

LEVEL CHECK PROCEDURE IN THIS SECTION FOR THE

CORRECT PROCEDURES FOR CHECKING THE CRANKCASE

OIL.

• Check for obvious loose mounting nuts and

bolts.

• Inspect all hoses, ttings, valves and seals for

leaks and proper operation. Repair or replace

leaking or malfunctioning components before

operating the system.

• Make sure cooling water is owing to the

plunger packing seals when the charge water

is activated. Constant water ow is essential

to lubricate and cool the seals. Adjust ow

with the metering valves or replace packing

if necessary.

• Make sure the cooling water sump and drain

are clean for proper drainage.

• Check for water dripping from the UHP Pump

manifold weep holes during the high pressure

test. Water dripping from the square holes

indicates the face seals are leaking. Water

leaking from round holes indicates the high

pressure seals are leaking. Find and correct

the problem before waterblasting.

• Test the diverter (dump) valve for proper op-

eration daily. Never operate the system if the

dump valve is not working properly.

• Test the manual bypass valve and make sure

it is operating properly.

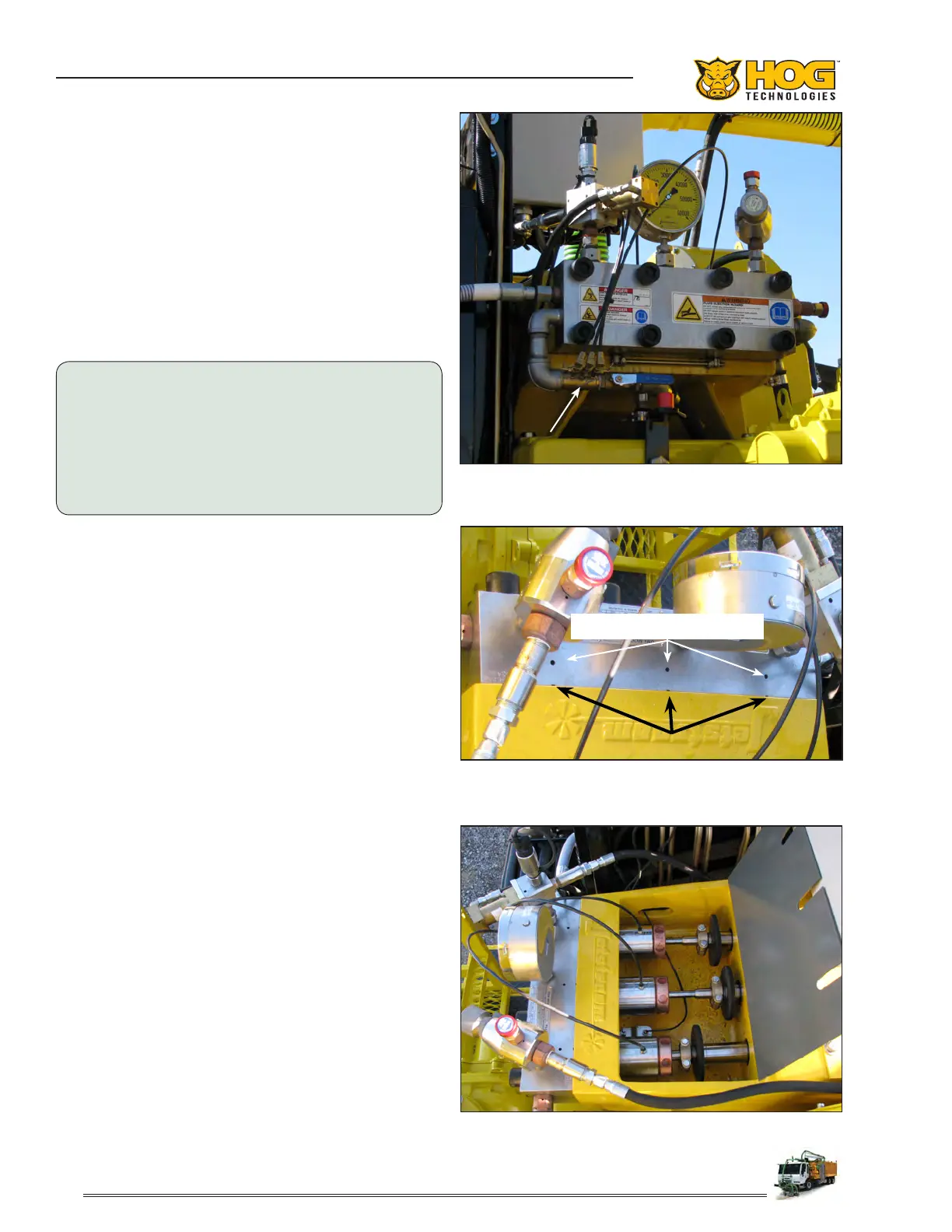

UHP Pump & Packing Lube Metering Valves

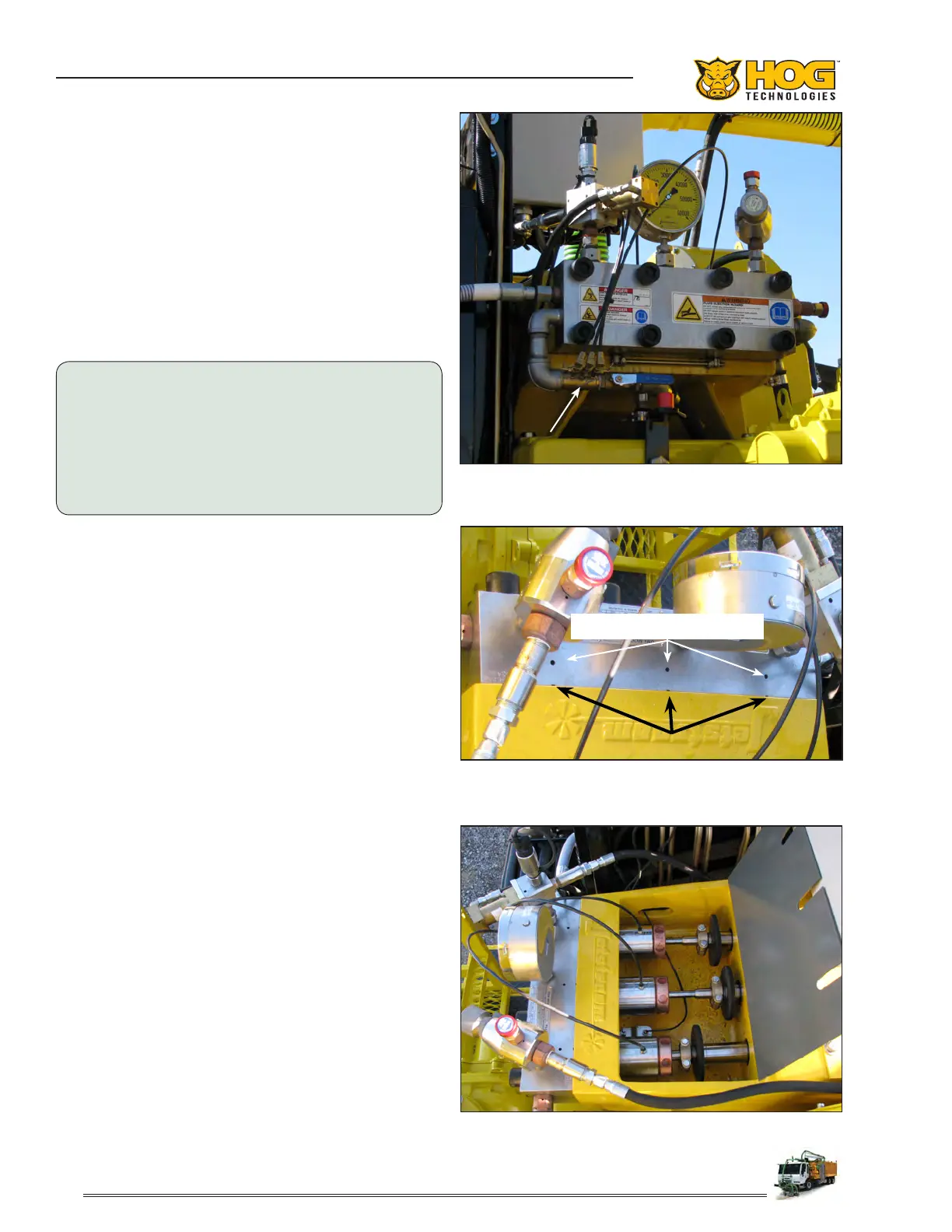

UHP Pump Packing Lube Lines & Sump

Metering Valves

UHP Pump Weep Holes

Face Seal Weep Holes

High Pressure Weep Holes

Loading...

Loading...