135

Scheduled Maintenance

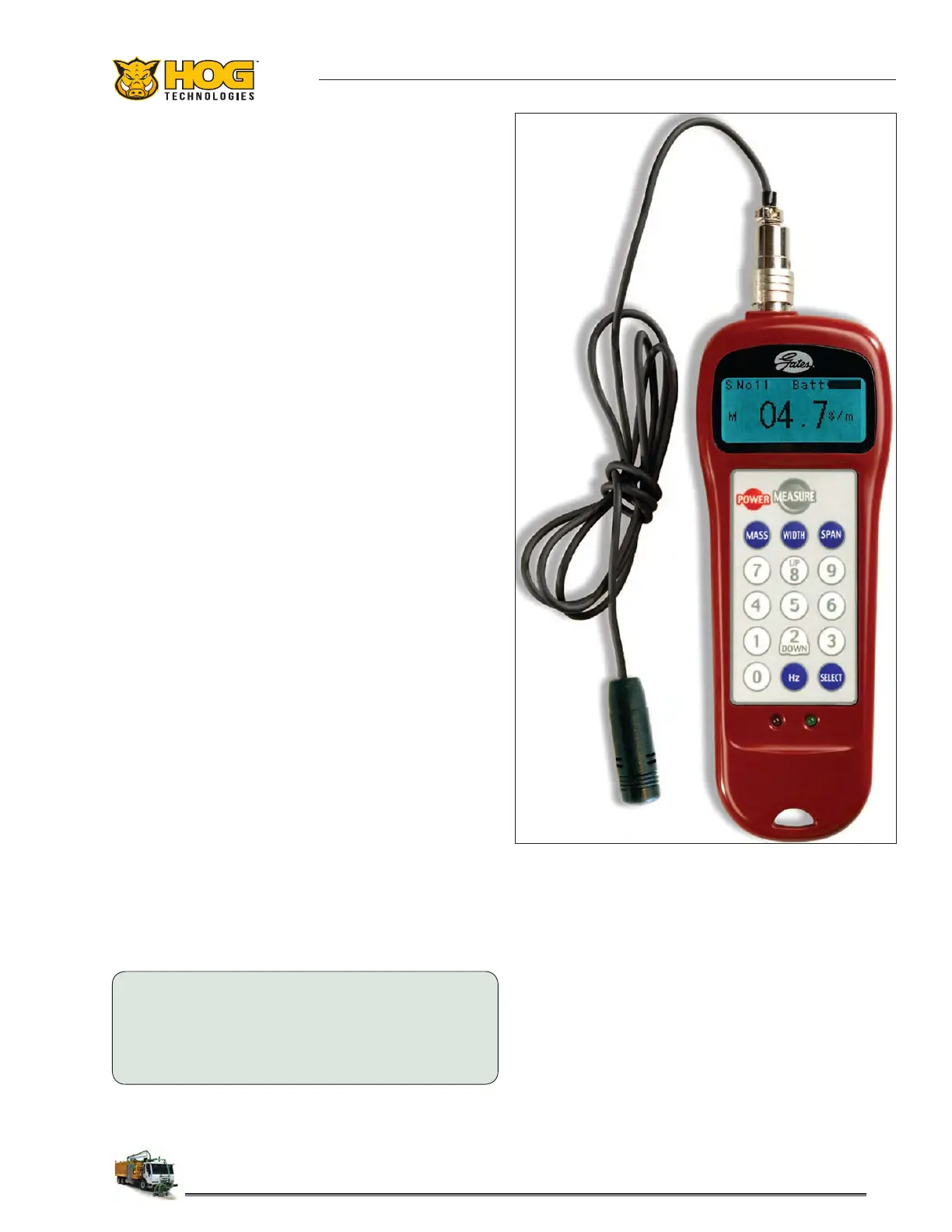

Typical Gates Sonic Tension Meter

5.13 Blower & UHP Pump Drive

Belt Adjustment Procedure

Checking Belt Tension

Check drive belt tension, pulleys and belt align-

ment every 200 hours. Adjust or replace as re-

quired. The proper way to check belt tension is to

use a tension tester. While a simple spring scale

type tester will do the job, the more sophisticated

sonic tension meter is the only method recom-

mended by Hog Technologies.

Make sure the waterblasting system is shutdown

with the truck in the service position before check-

ing the belt tension or adjusting the belts.

Using a sonic tension meter to check belt

tension:

The sonic tension meter detects the vibration

frequency in the belt span and converts that mea-

surement into the actual static tension in the belt.

Begin by entering the belt unit weight, belt width

and the span length. To measure the span vibra-

tion, press the “measure” button on the meter,

tap the belt span while holding the microphone

approximately 1/4” (.6 Mm) away from the back of

the belt. The tension meter will display the static

tension vibration frequency. If the frequency is

lower than the minimum recommended frequency,

the belt should be tightened. If it is higher than

the maximum recommended frequency the belt

should be loosened.

Blower Belt Tension Frequency Specica-

tions:

• New Belt = 46-48 Hz

• Used Belt (more than 20 hours of operation)

= 39-41 Hz

UHP Pump Belt Tension Frequency Speci-

cations:

• New Belt = 61-63 Hz

• Used Belt (more than 20 hours of operation)

= 52-55 Hz

NOTICE:

THE PROCEDURE IN THIS EXAMPLE IS FOR THE GATES

SONIC TENSION METER. SONIC METERS FROM DIFFERENT

MANUFACTURERS WILL REQUIRE PROCEDURES UNIQUE

TO THOSE METERS.

Loading...

Loading...