136

Scheduled Maintenance

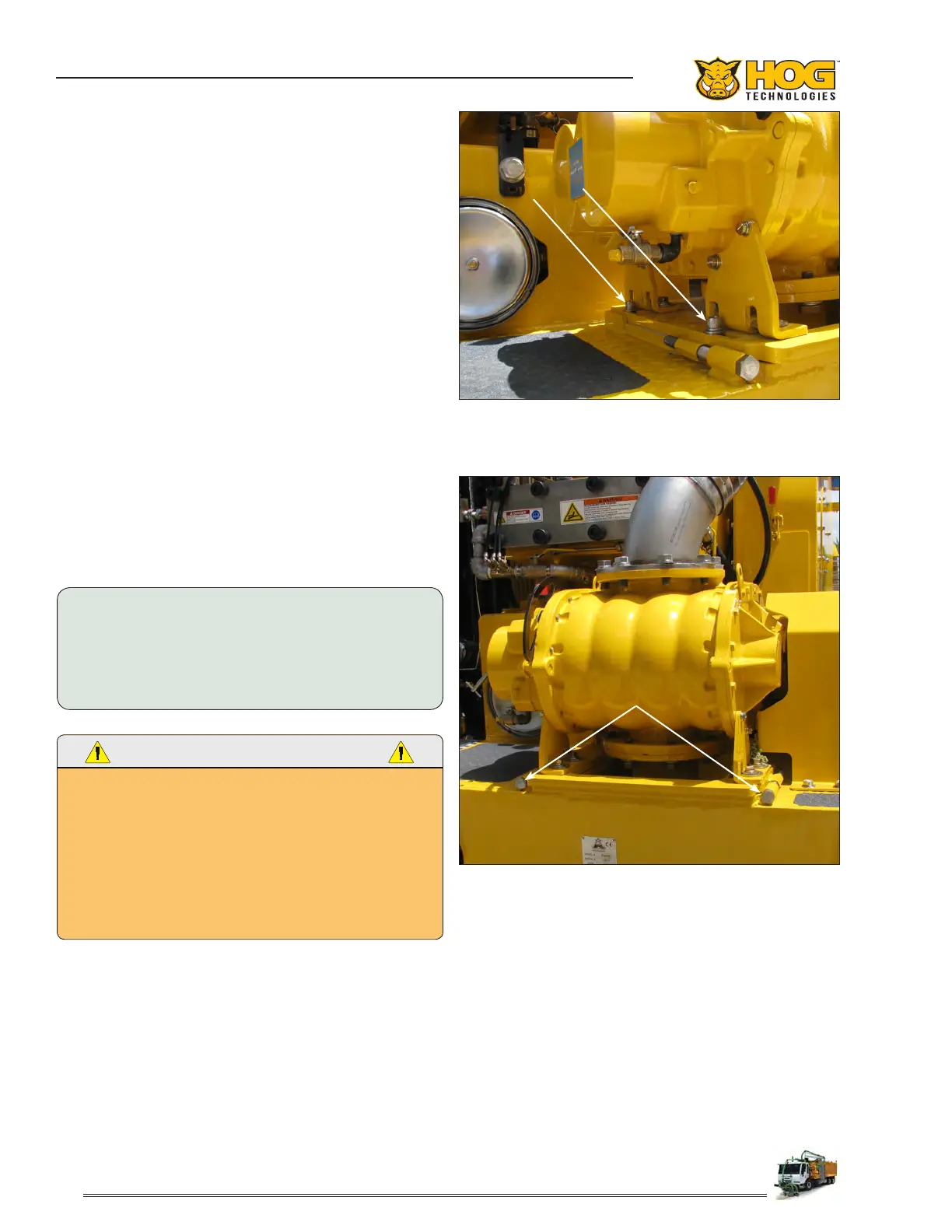

Blower Mounting Plate Bolts

Blower Adjusting Bolts

Blower Drive Belt Tension Adjustment

1. Loosen the four bolts on the slotted hoes on

the mounting plate just enough to allow the

plate to move. Make sure not to loosen them

too much.

2. Rotate the adjusting bolts on each side of the

blower mount equally to adjust the belt to the

proper specication. Use a sonic tension meter

to test for proper tension. (See specications

in this section)

3. Tighten the bolts on the slotted holes.

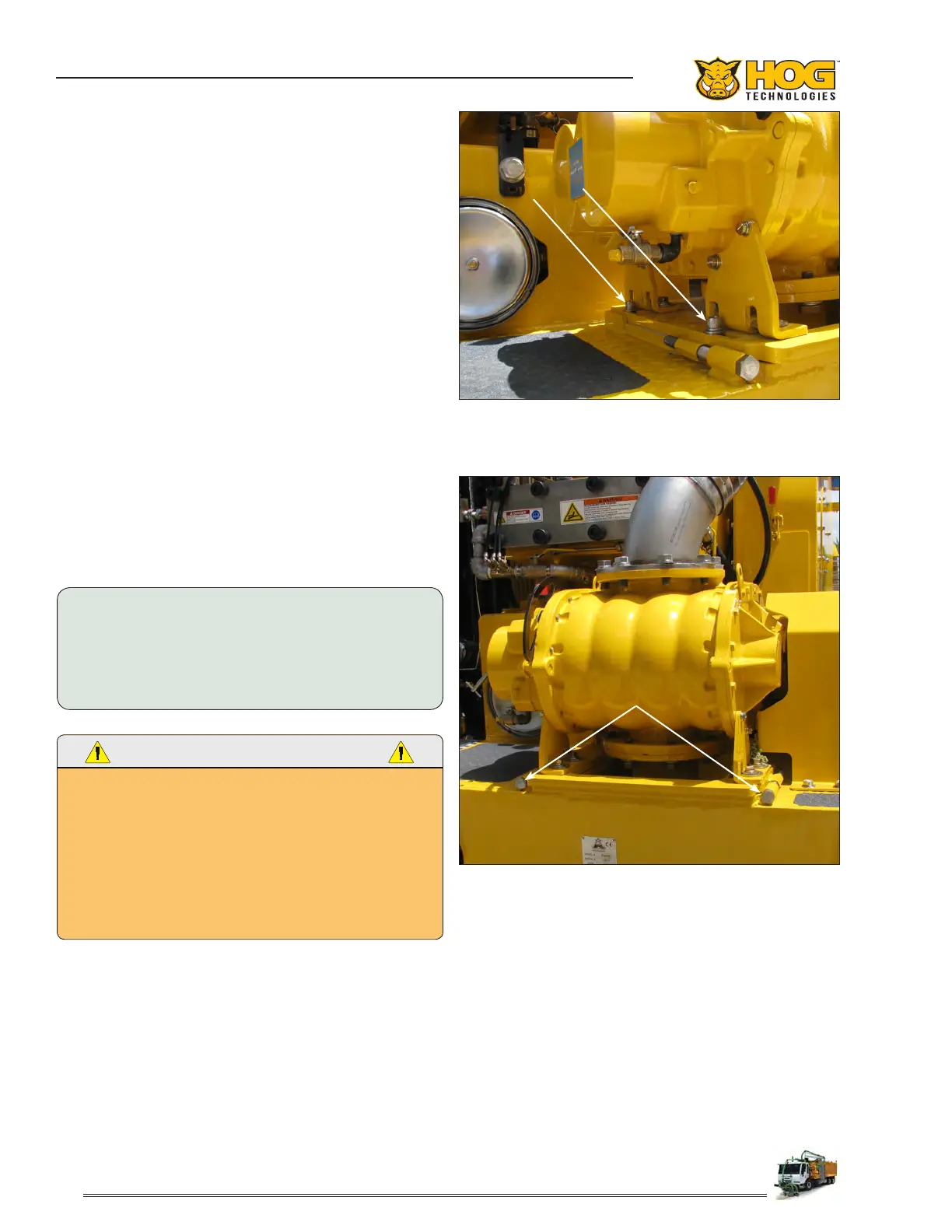

4. Start the engine, engage the PTO and activate

the 40K clutch at idle speed for 30 seconds.

5. Deactivate the 40K clutch; disengage the PTO

and shutdown the engine.

6. Check that the belt is riding on the center of

the pulleys. If it is riding hard on either side of

the pulleys, the blower will have to be aligned

slightly using the mounting plate adjusting

bolts. Repeat alignment and tension steps

until the belt is set to the proper tension and

centered on the pulleys.

NOTICE:

APPLY GREASE OR ANTI SEIZE TO THE THREADS OF THE

BLOWER AND UHP PUMP ADJUSTING BOLTS EACH TIME

THE BELTS ARE ADJUSTED TO HELP PREVENT CORROSION

AND ENSURE THE ADJUSTING BOLTS WILL TURN WHEN

ADJUSTMENT IS REQUIRED.

THE DRIVE BELTS CAN CAUSE SEVERE DAMAGE TO

PULLEYS, SHAFTS AND BEARINGS IF THEY ARE ADJUSTED

TOO TIGHT OR MISALIGNED. THIS CAN CAUSE SEVERE

DAMAGE TO DRIVE SYSTEM COMPONENTS AND INJURY

TO PERSONNEL IF DAMAGED COMPONENTS ARE

THROWN FROM THE MACHINE. ALWAYS MAKE SURE THE

BELTS ARE PROPERLY ALIGNED AND SET TO THE BELT

MANUFACTURERS SPECIFICATIONS WHEN THEY REQUIRE

ADJUSTMENT. NEVER OVER TIGHTEN THE BELTS.

Loading...

Loading...