165

Scheduled Maintenance

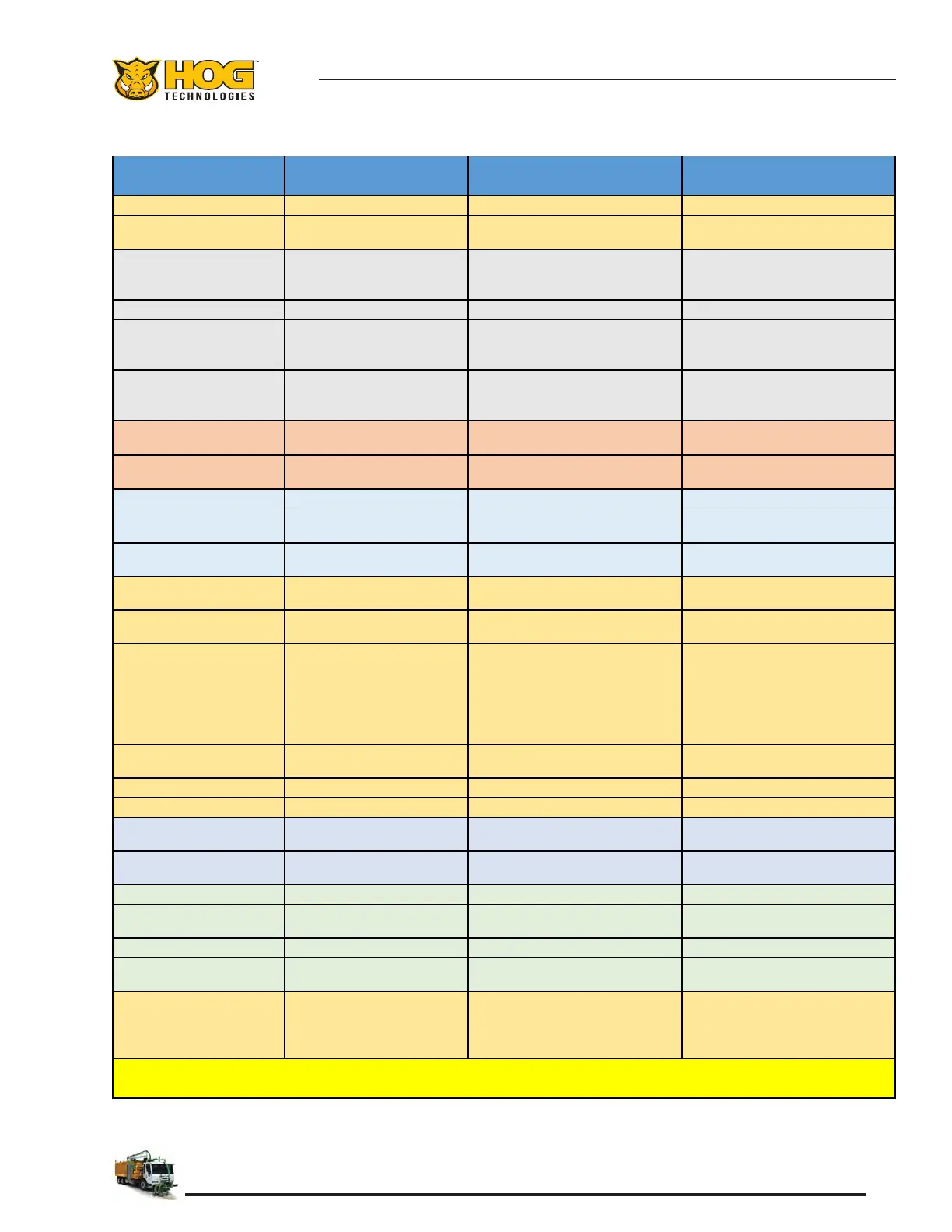

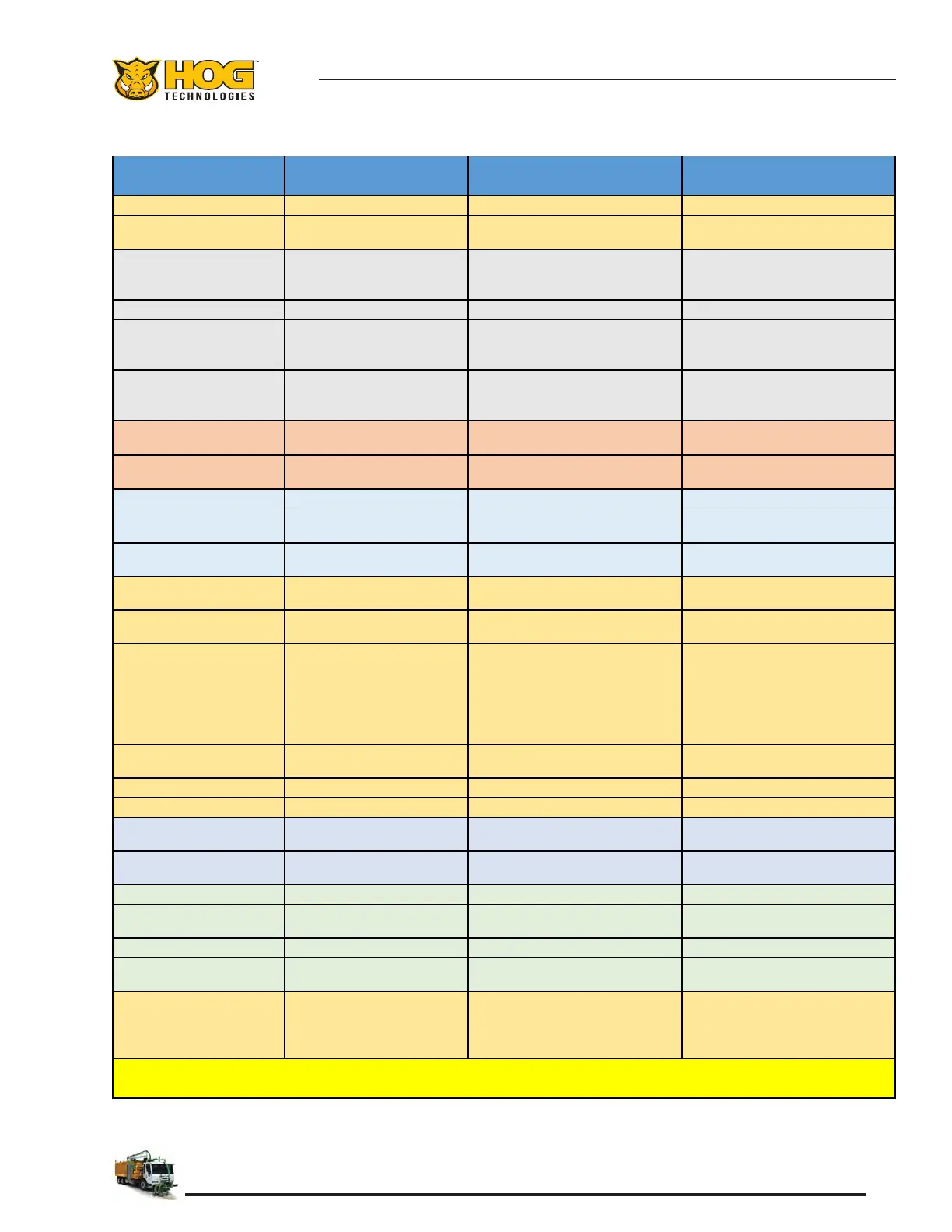

5.22 SH8000 Maintenance Matrix

SH8000 Maintenance Matrix

EQUIPMENT COMPONENT INTERVALS LUBRICATION SPECIFICATIONS

Truck Engine

Oil and Filter

Refer to Truck Operating Manual Refer to Truck Operating Manual

Driveline

Transmission, Drive shafts,

Differential

Refer to Truck Operating Manual Refer to Truck Operating Manual

OMSI

Front Section

Then Every 200 Hours

Castrol TranSynd Full Synthetis ATF

or Equivalent

OMSI 40K OMSI Filter Every Fluid Change OMSI Filter

OMSI Rear Main Gearbox

Then Every 500 Hours or 12 months

75w90 Gear Oil

OMSI

Planetary Gearbox

Then Every 500 Hours or 12 months

75w90 Gear Oil

Output Shaft

Shaft Between 40K Clutch And

The Combo Skid

Weekly General Purpose Grease

Pillow Block Bearings

3"Shaft Pillow Block Bearings

Daily (SH8000 only) General Purpose Grease

Hydraulic System Hydraulic Fluid Reservoir 500 hours or yearly Aw68

changed

Hydraulic System High Pressure Hydraulic Filter

After First 100 hours

then every 500 hours

Hydraulic Filter

Hydraulic System Low Pressure Hydraulic Filter

After First 100 hours

then every 500 hours

Hydraulic Filter

Roots Vacuum Blower Blower Gear Case oil

After First 50 hours and then every

1,000 hours or yearly

ISO VG 320 Roots Oil

High Temp - Synthetic

Dresser Roots Blower

Pulley End Bearings

(Grease Fittings)

Daily

(2 pumps Each Fitting)

Shell GADUS S2 U1000 2 Grease

Howden Roots Vacuum

Blower

(Grease Fittings)

(2 pumps Each Fitting)

Blowers with serial # beginning

before 1608A

Shell

GADUS S2 U1000 2 Grease

Blowers with serial # beginning with

1608A and later

Royal Purple Synthetic Grease

Tuthill Blower

Pulley End Bearings

(Grease Fittings)

Daily

(2 pumps Each Fitting)

Tuthill Lithium Complex Grease

Roots Vacuum Blower Vacuum Filter Inspect Daily

Clean or Replace

Kunkle Valve Internal Relief Valve Cycle several times each week

WD-40 or Equivalent

changed

Jetstream Pump Uni-valves

Every 100 hours

(Lapping Procedure)

NA

Jetstream Pump Crankcase Oil

After First 100 hours and then every

500 hours

75w90 Gear Oil

Hog Head Thru-Shaft Motor Bearings Daily Mobil Polyrex EM Grease

Hog Head

Thru-Shaft Motor Pre-load

Adjustment

Weekly NA

Hog Arm Chassis Wheels And Casters Daily General Purpose Grease

Hog Arm

Bearings, Hinges and Other

Grease fittings

Weekly General Purpose Grease

General Grease Points

Door Hinges, Debris Tank Tilt

Pins, Vacuum Door Hinges, Ball

Valves, Latches, ETC

More Frequently If Required

General Purpose Grease

This chart is a guide only. It should never be to supersede equipment manufacturer's specifications.

Please refer to the manufacturer's operation and maintenance manuals for additional information.

Loading...

Loading...