167

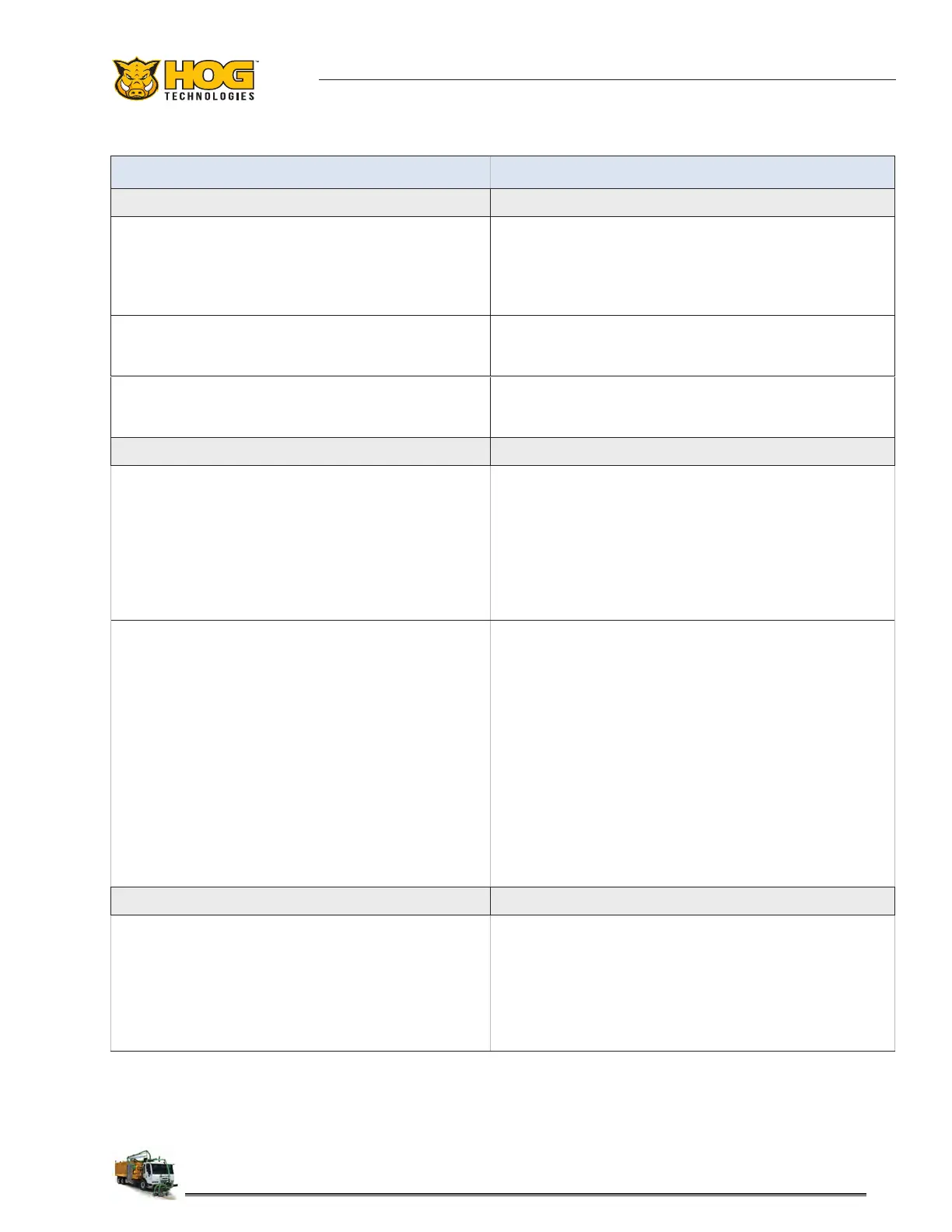

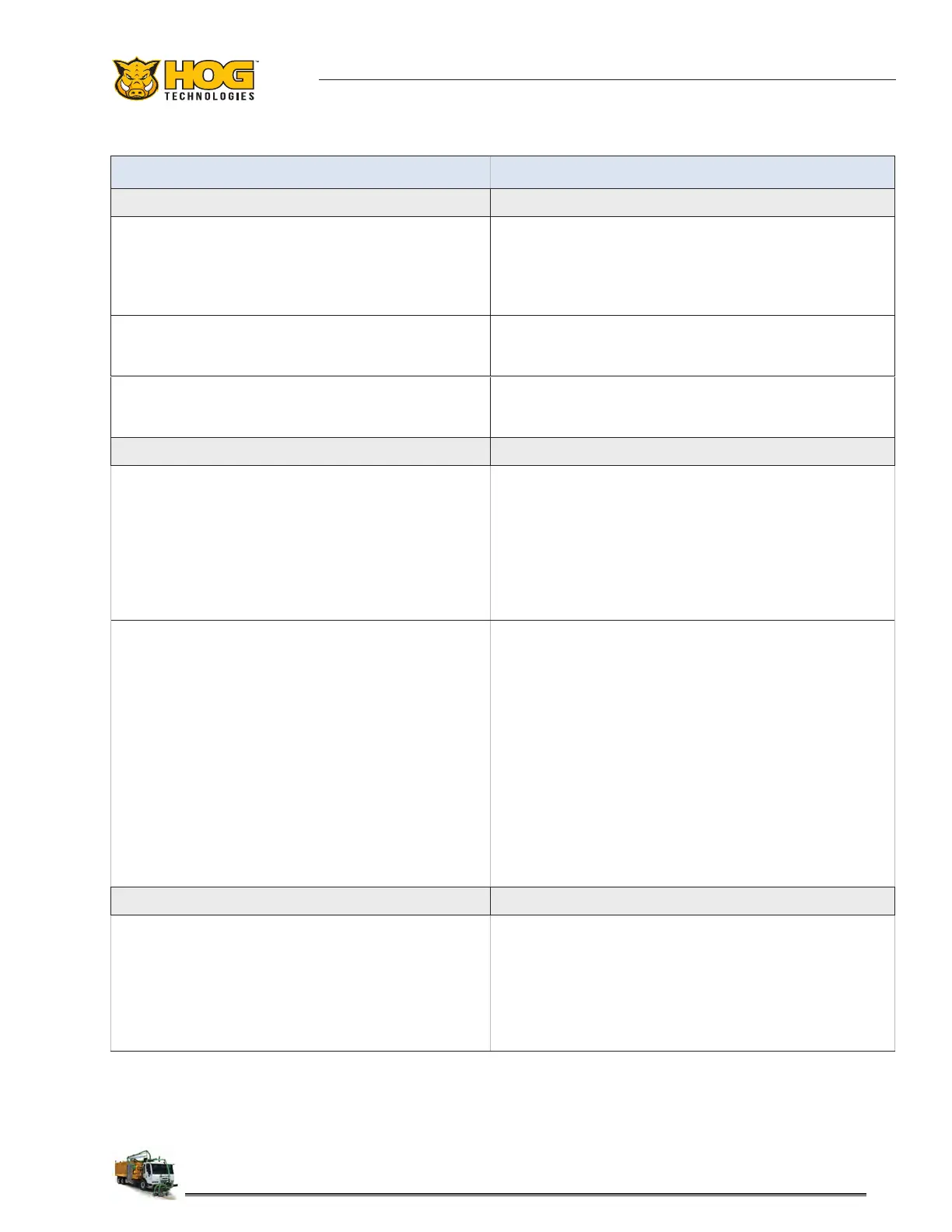

PROBLEM

CAUSE AND SOLUTION

Noises & Vibrations

Blower system noise. • Loose blower belts or pump belts. Adjust or

replace belts.

• Blower or drive belts out of alignment. Align

and adjust belts.

Hog Head noise. • Hog Head rotation extremely high. Turn head

rotation dial counterclockwise to reduce head

speed.

High pressure pump noise. • UHP pump pulley out of balance. Balance the

pulley.

Hog Arm & Hog Head

Hog arm won’t raise.

• Float mode activated. Disengage oat function.

• Hydraulics not engaged. Engage PTO to activate

hydraulic system.

• Hydraulic uid low. Add uid to the hydraulic

uid reservoir.

• Hose or tting broken or leaking. Tighten loose

tting or replace broken hose or tting.

Spray bar doesn’t spin or spins slowly.

• Hydraulics not engaged. Make sure PTO is

engaged to activate hydraulic system.

• Debris packed around thru-shaft or spray bar.

Clean thru-shaft or spray bar.

• Hog Head shroud is concave and not convex.

Repair or replace shroud.

• Speed dial control is shut o. Turn the speed

dial clockwise.

• Electric connection is unplugged or no voltage to

coil. Check that LED light on coil is lit and repair

circuit or replace coil as necessary.

• Dirt shield is too tight. Remove dirt shield and

install new dirt shield only nger tight.

UHP Pump & High Pressure System

Fluctuation or pulsing of 40k gauge or inlet

pressure gauge.

• Valve may be pitted or cracked. Remove valve

and check seats for damage - replace or rebuild.

• Leaking packing. Determine which is leaking

and change, ush and replace.

• PTO slipping. Allow PTO to cool and make

adjustments to tighten PTO.

Appendix 1:

Troubleshooting

Waterblasting System Troubleshooting

Loading...

Loading...