118

Scheduled Maintenance

5.5 Checking UHP Pump Oil Level

& Changing Crankcase Oil

Checking Oil Level

Jetstream ultra high pressure pumps have specic

procedures for checking the crankcase oil while

the pump is operating and when it is shutdown.

Following the correct procedure is critical to main-

taining the correct oil level and to prevent the

possibility of overlling the crankcase, which will

damage the pump.

The pump power end uses a splash/gravity oil

circulation system for internal lubrication and oil

distribution. The crankcase has an upper sump

that is lled by the splashing action of the crank-

shaft as it rotates. Oil slowly drains from the

upper sump through small holes which provide

lubrication to certain components that would not

be properly lubricated otherwise.

The upper sump holds a large volume of oil that

drains very slowly back into the main sump. Con-

sequently, there is a signicant dierence in the

oil level while the pump is operating and when it

is shutdown. It takes 5 to 8 hours for oil in the

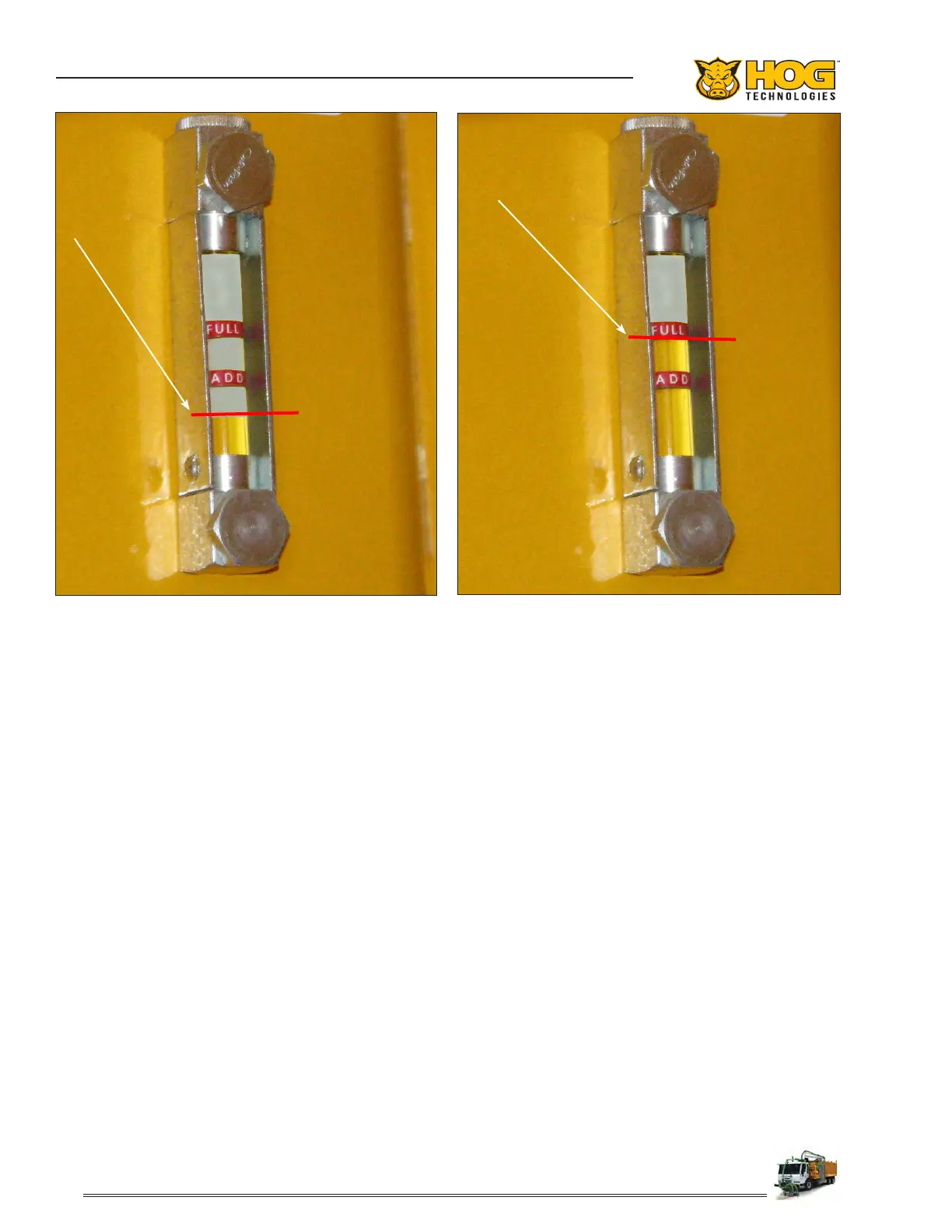

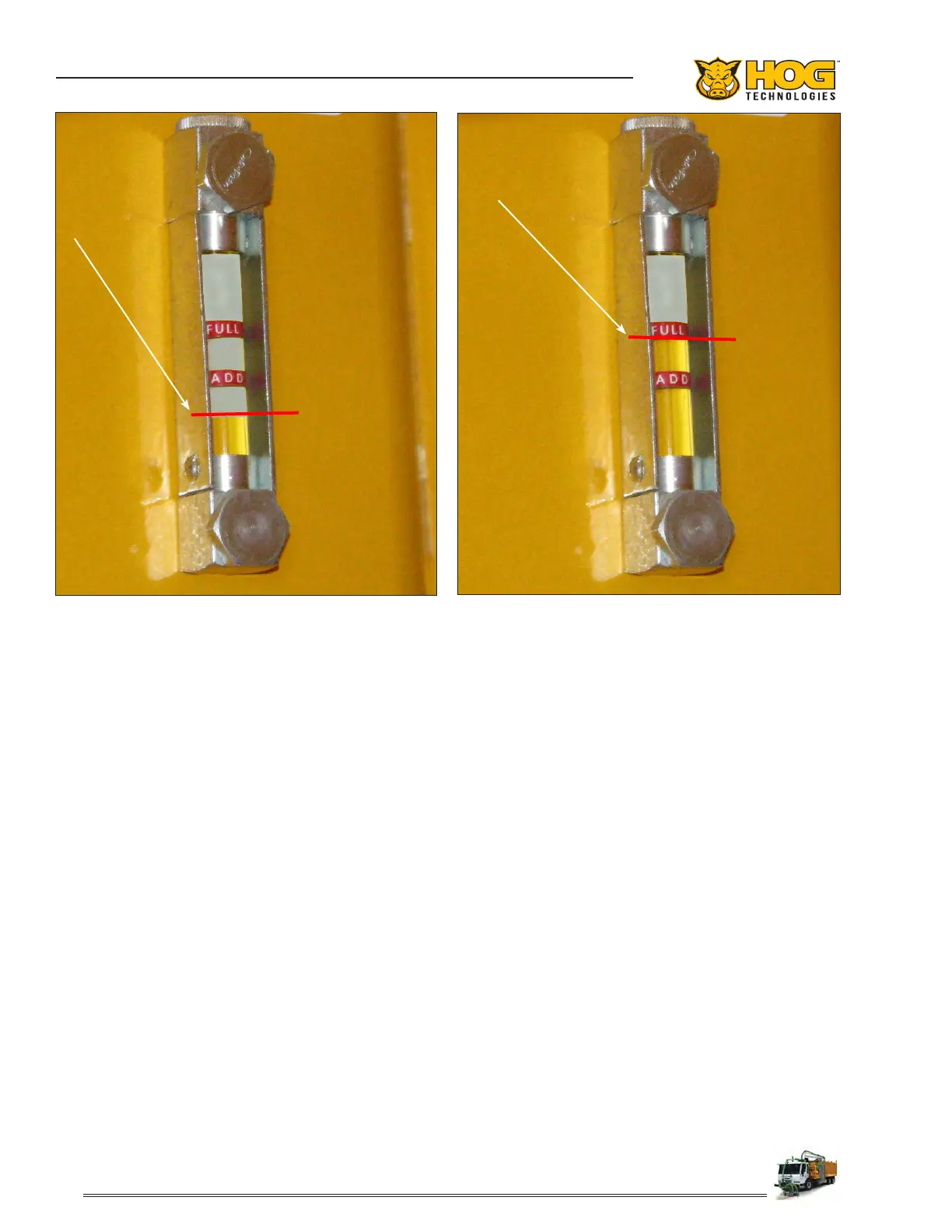

Crankcase Oil Level - Pump Running Crankcase Oil Level - Pump Shutdown 5 To 8 Hours

upper sump to completely drain to the main sump

after the pump is shutdown. As a result, the pump

must sit overnight before an accurate crankcase

oil level is indicated in the sight glass when the

pump is not operating.

Because of the crankcase design, the most accu-

rate way to check the oil level during operation is

while the pump is running. The following section

outlines the procedures for checking the crankcase

oil level with the pump running or when the pump

is shutdown. Always make sure the truck is parked

on level ground with the wheels blocked before

checking the crankcase oil level.

Crankcase Oil Level - Pump Operating:

1. Make sure the crankcase oil level is at the full

mark, then turn the 40K Clutch ON to activate

the high pressure pump.

2. Operate the pump for 20 to 30 minutes to al-

low the upper sump to ll and the oil level in

the main sump to stabilize.

Loading...

Loading...