4545

Stripe Hog Systems

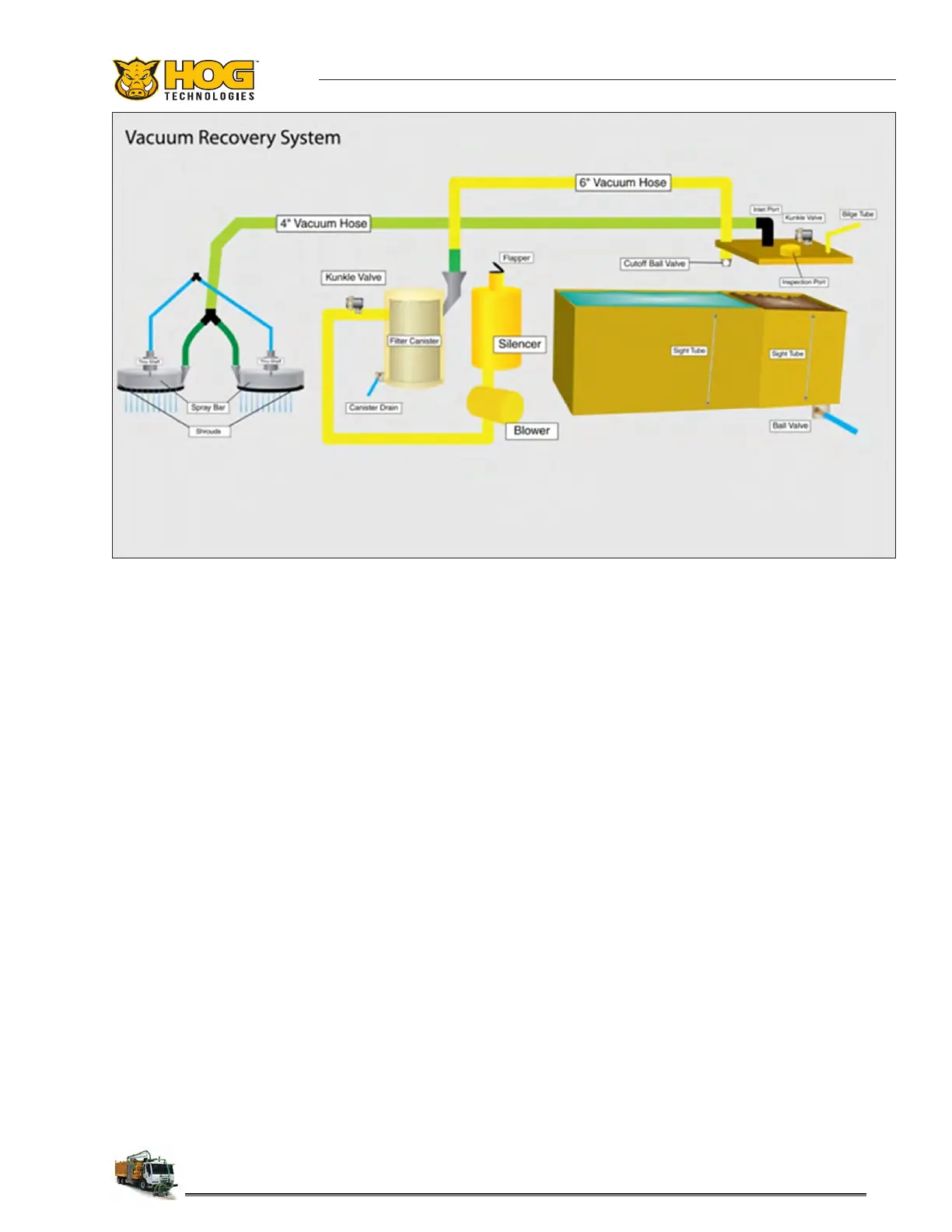

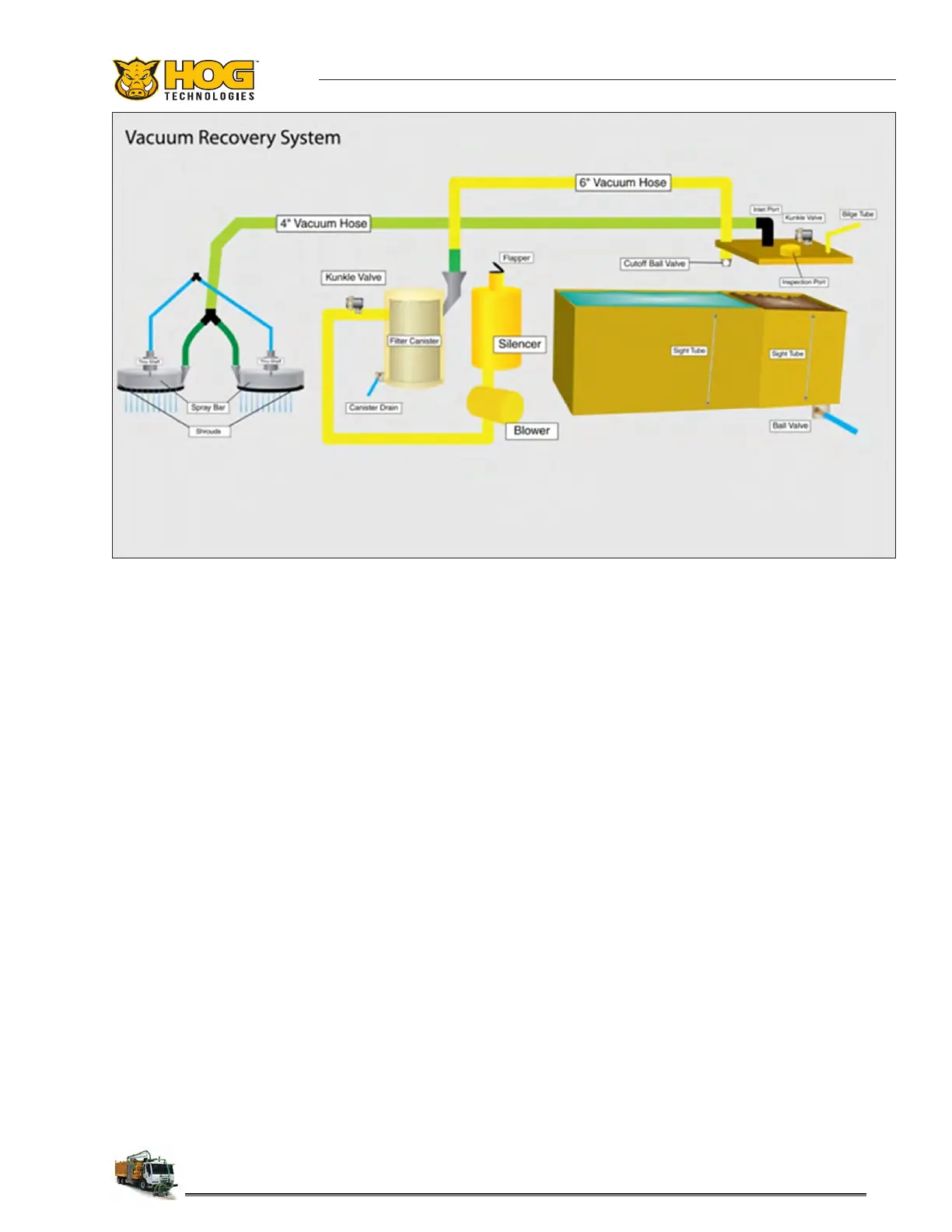

2.7 Vacuum Recovery System

Overview

The vacuum recovery system consists of a high

performance blower, vacuum hoses, lter canis-

ter, relief valves and a debris tank. The system is

powered by the main truck engine and activated

whenever the PTO and 40K Clutch is engaged.

The blower creates vacuum in the lter canister,

debris tank, vacuum hoses and blasting heads.

A lter located in the lter canister protects the

blower and exible hoses with quick disconnect

ttings provide vacuum to the truck mounted

blasting heads.

The vacuum recovery system is critical to pro-

ductivity on most waterblasting projects . Airport

specications require minimal FOD (foreign, ob-

jects, debris) after blasting as possible due to the

possibility of removal projects on active taxiways

and runways.

On road construction sites, vacuum recovery is

critical to productivity by removing excess water

and debris from the road surface. Paint crews are

generally on location to apply new line markings

immediately after existing markings have been

removed. The eciency of the vacuum system

in removing water and debris from the road sur-

face after blasting determines how quickly the

new markings can be applied. The waterblasting

vacuum recovery system only leaves a damp strip

of moisture on the road surface after removal al-

lowing painting shortly after blasting operations

are completed.

Proper Airow And Safety Valves

Maintaining maximum engine RPM and airow at

the blasting heads is essential for achieving opti-

mum vacuum performance. The vacuum blower

creates negative pressure in the blast head shroud

pulling air past the wear brush into the shroud,

then transporting air, water and debris from the

shroud through the 4” vacuum hose to the inlet

port on the debris tank. The water and debris is

separated from the airow and deposited into a

debris bag or directly into the tank, depending on

the truck options selected. The ow of air contin-

ues from the debris tank through the 6” vacuum

hose to the lter canister where the air is ltered

and residual water is separated and collected.

Loading...

Loading...