3535

Stripe Hog Systems

2.5 Thru-shaft, Spray Bars,

Protectors And Nozzles

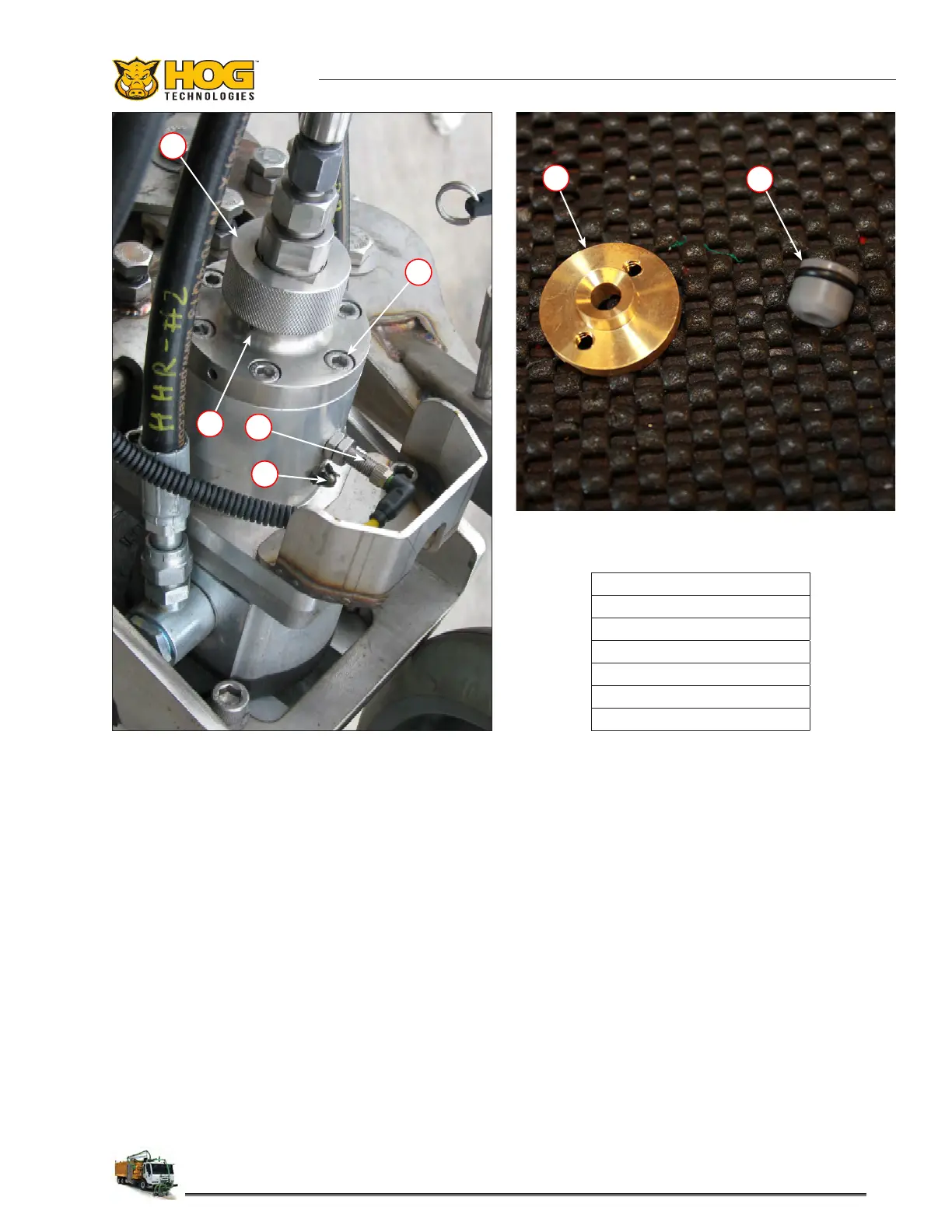

Thru-shaft Motor

The hydraulic powered thru-shaft motor rotates

the spray bar on the blasting head assembly.

The center of the rotating shaft is drilled to allow

high pressure water to pass through the shaft to

the spray bar. A specially designed swivel seal

and brass backup ring create a water tight, high

pressure seal at the connection of the high pres-

sure hose to the thru-shaft. The hose is secured

to the rotating shaft housing by the swivel nut.

The swivel nut is hand tightened. If the nut

becomes loose, the hose will wobble and damage

the swivel seal. Additionally, if the swivel nut is

overtightened by using a pipe wrench or pliers,

the swivel seal will be damaged. The swivel nut

must be checked daily to ensure it is tight and

that the swivel seal is not leaking. Any water drip-

ping from the weep holes just below the swivel

nut while the system is pressurized indicates the

seal is leaking and must be replaced. Operating

the blasting heads with a leaking swivel seal will

cause complete failure of the seal, stopping blast-

ing operations.

The RPM of the thru-shaft motor on each blast-

ing head is independently controlled by the PLC

mounted on the Joystick console. A speed sensor

on each thru-shaft motor housing continuously

monitors the RPM of the thru-shaft/spray bar and

sends the data to the PLC where the RPM of each

spray bar is displayed on separate windows on

the display panel. During blasting operations, the

operator can monitor the RPM of each spray bar

and make adjustments as necessary.

1. Swivel Nut

2. Swivel Seal Weep Hole

3. Thru-shaft Cover

4. Grease Fitting

5. Speed Sensor

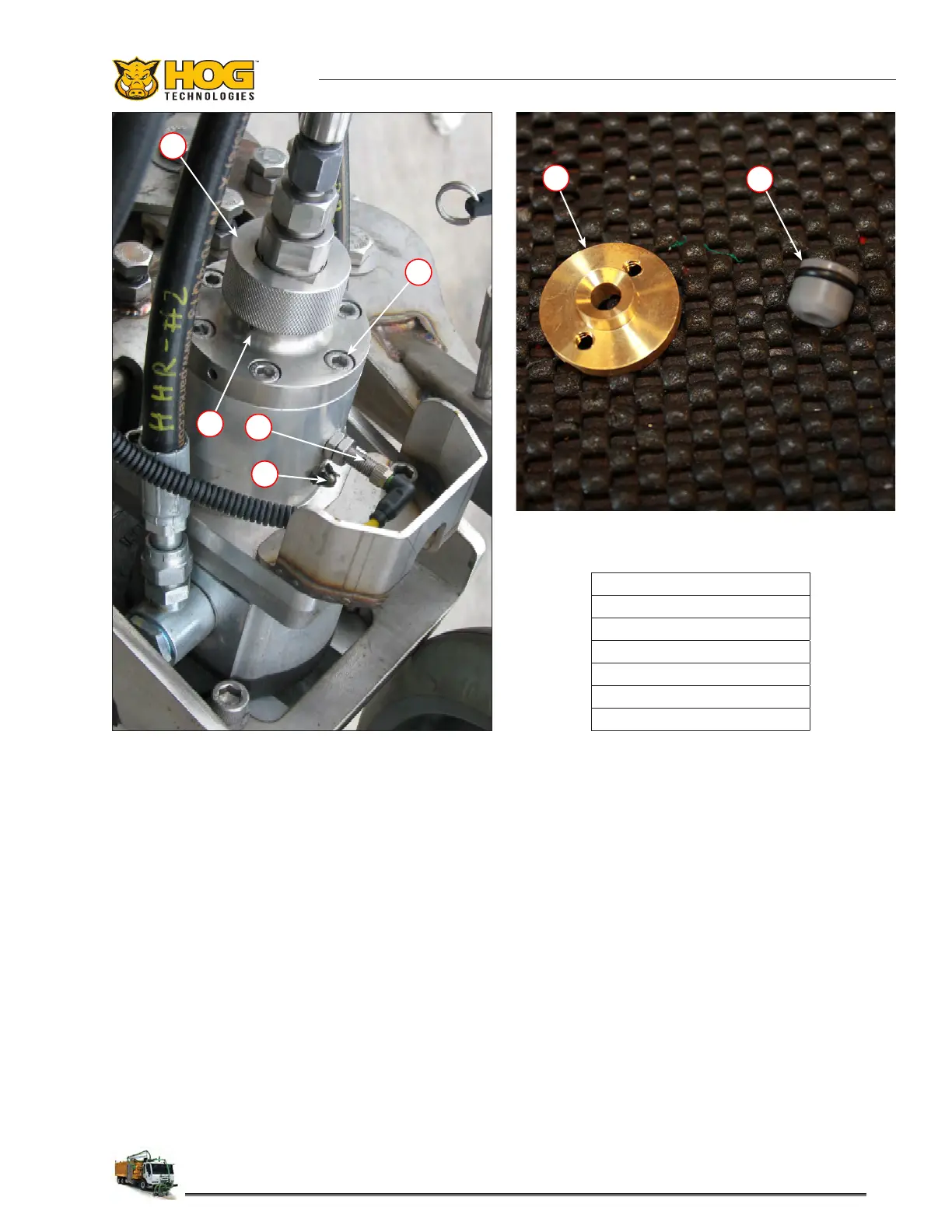

6. Brass Backup Ring

7. Swivel Seal

1

3

4

5

2

6

7

Thru-shaft Motor Components

Swivel Seal & Brass Backup Ring

Loading...

Loading...