108

General Maintenance

5. Activate the truck and the waterblasting sys-

tem.

6. Turn the charge pump on and ush debris from

the spray bar with low charge pressure water.

7. Once the spray bar is ushed, deactivate the

waterblasting system and shutdown the truck.

8. Apply a light coat of anti-seize to the threads

on the new nozzles.

9. Install the nozzles into the spray bar being

careful not to get any anti-sieze on the seat

area of the nozzle or the spray bar.

10. Tighten each nozzle nger tight. Then torque

each nozzle to 10 ft lbs.

11. Reactivate the truck and the waterblasting

system by following the steps in the Start Up

Procedure.

12. Set the Head Rotation speed dial to 0, then

turn the 40K Clutch switch ON to activate the

ultra high pressure water system.

13. Make sure all personnel are well clear of the

blasting heads, then press the START button

to activate the high pressure system and set

the operating pressure to a safe level. Stay-

ing well clear of the water jets, no closer than

18”, visually inspect the spray pattern of each

nozzle.

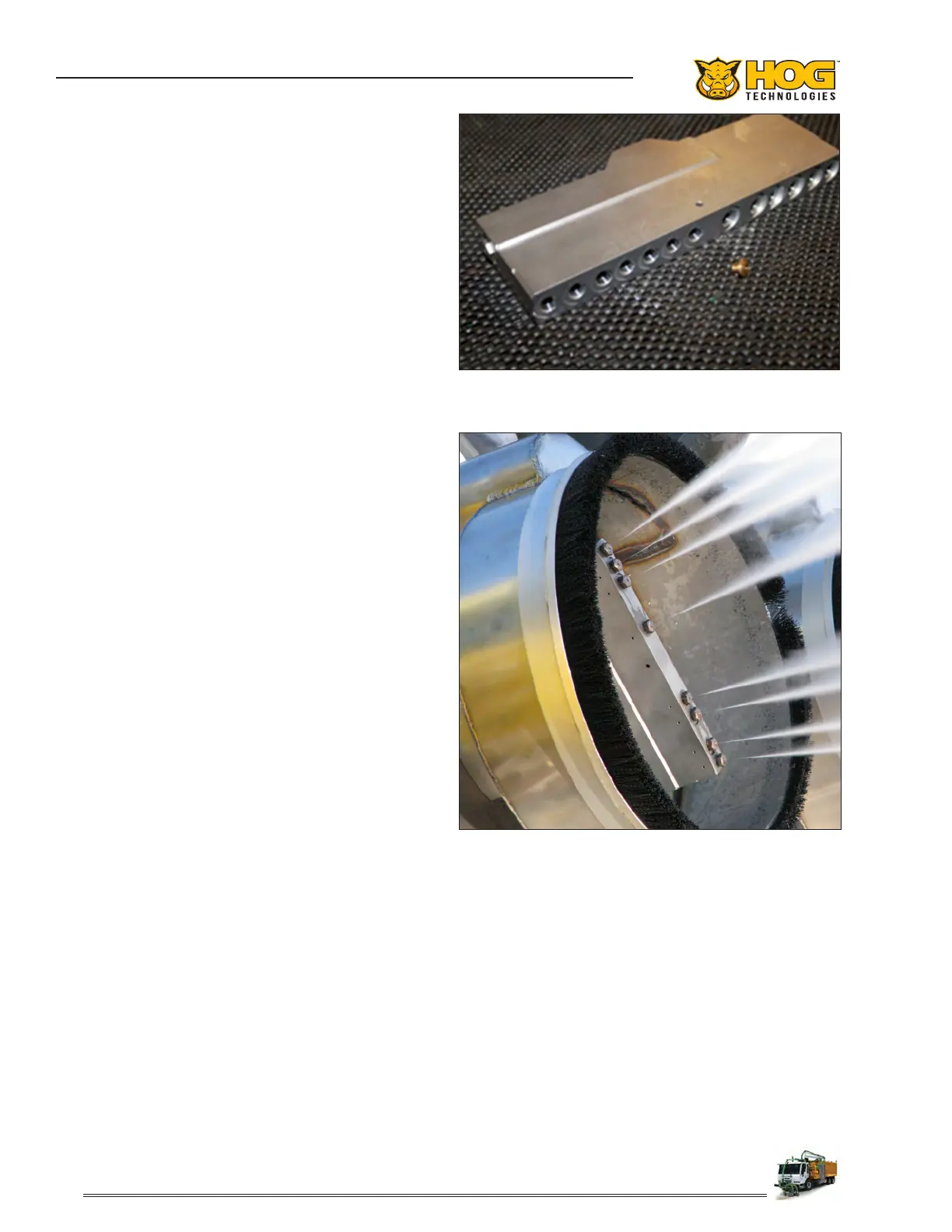

14. Conrm at least a 1 inch, needle tight, water

jet is coming from each nozzle.

15. Deactivate the waterblasting system and shut-

down the truck.

16. Replace the spray bar protective cover and

gasket.

Nozzle Pressure Test - All Nozzles Good

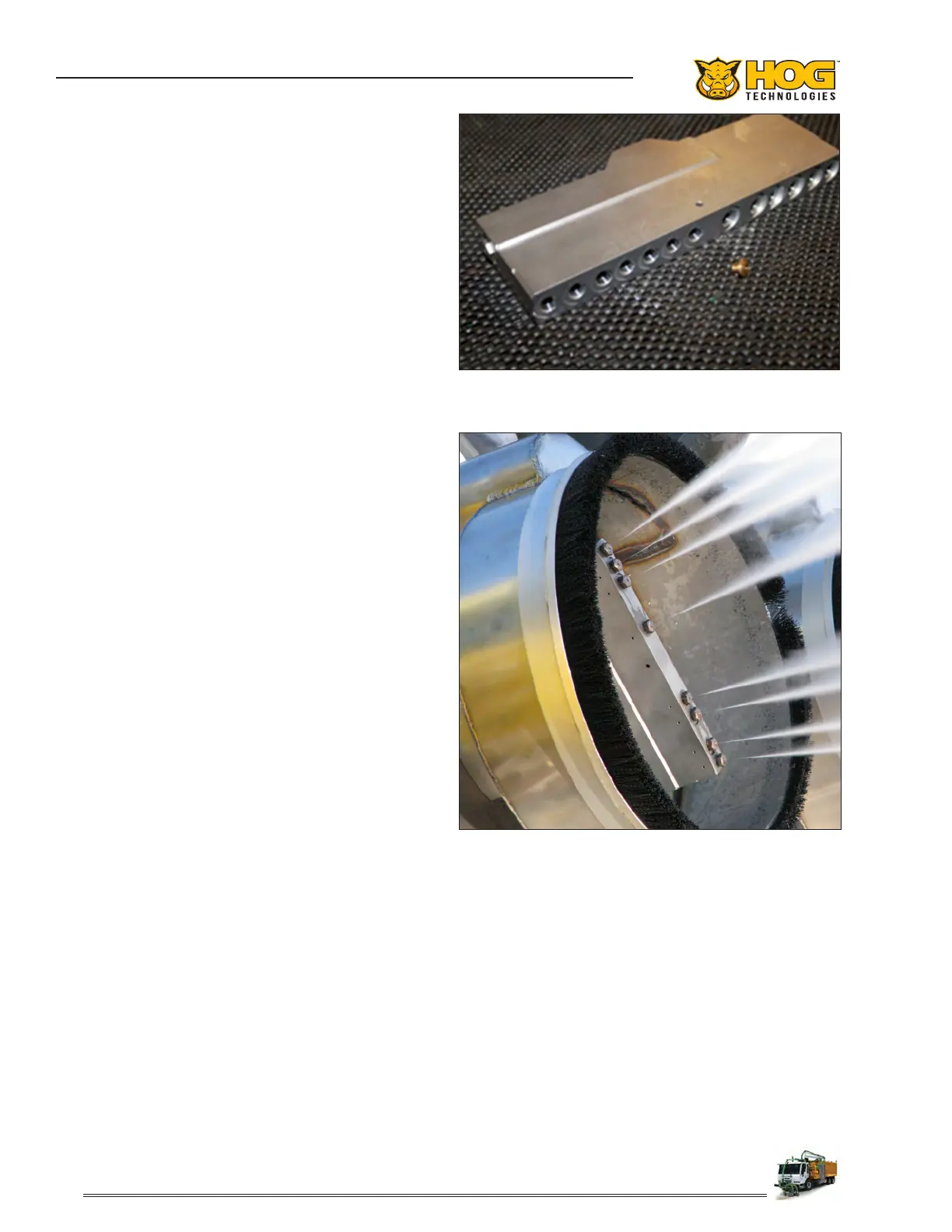

Typical Spray Bar & Nozzle

Loading...

Loading...