2020

Stripe Hog Systems

NOTICE:

THE UHP PUMP CAN CAVITATE IF THE CHARGE WATER

PRESSURE DROPS BELOW 25 PSI (1.7 BAR.) CAVITATION

CAN CAUSE SEVERE DAMAGE TO THE UHP PUMP AND

SHOULD NEVER BE ALLOWED TO OCCUR. YOU SHOULD

ALWAYS MONITOR THE CHARGE WATER PRESSURE AND

NEVER OPERATE THE UHP PUMP WHEN THE CHARGE

WATER PRESSURE DROPS BELOW 30 PSI (2.1 BAR.)

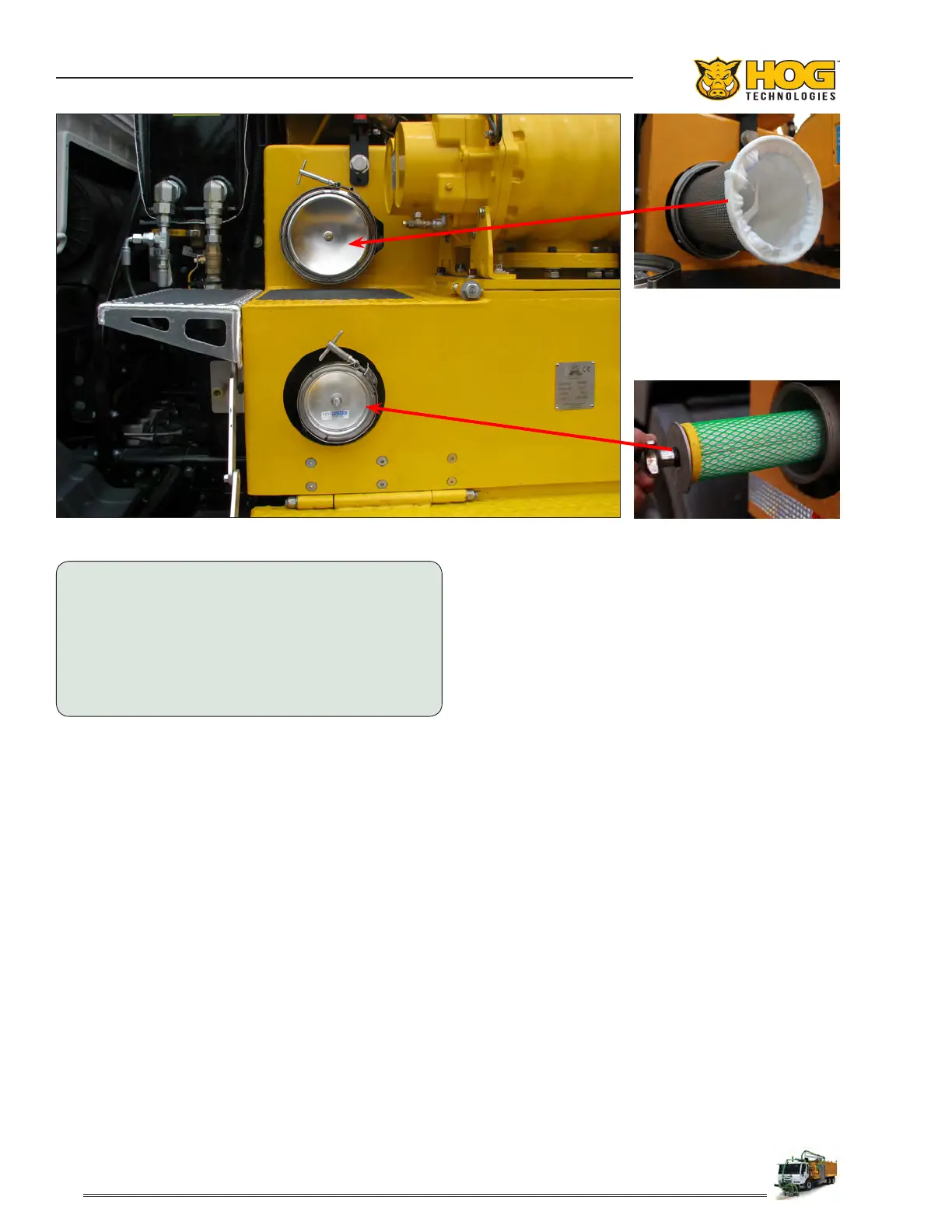

Filters

A two stage lter system in the supply line from

the charge pump to the ultra-high pressure pump

protects the high pressure pump and system from

debris or contaminants in the water supply.

The rst stage lter is a nominal 10 micron bag

lter that traps larger particles and the second

stage is a 1 micron cartridge lter that traps

smaller particles.

The lters are critical to the proper operation of

the Ultra-high pressure water system. They should

be checked daily and changed when the charge

pressure drops to 30 psi (Refer to lter change

procedure in Maintenance section of this manual).

Dirty charge water lters are the number one

reason for low charge water pressure. Sensors

in the charge water system will disengage the

40K clutch and the high pressure pump will shut

down if charge water pressure drops below 30

psi (2.1 BAR).

Operating with dirty lters can cause:

• Unwanted particles forced through the lter

resulting in premature failure of the parts.

• Cavitation in the ultra-high pressure pump

which will result in damage to the pump.

• Reduced ow of lube water to the packing seals

which could damage the seals.

Remember that the lters can be under pressure.

Always make sure the charge pump switch is OFF,

the PTO disengaged and the pressure has been

bled from the system before removing the lter

caps.

Always thoroughly ush the lter canisters and

charge water system when the lters are changed

and before activating the ultra-high pressure sys-

tem. A purge valve located on the low pressure

(charge water) side of the pump is opened to

purge the system after a lter change or to ush

the charge water side of the pump if the system

becomes contaminated. This valve is also used

when adding anti-freeze during cold weather

operations.

1 MICRON FILTER

10 MICRON FILTER

Two Stage Filter System

Loading...

Loading...