2525

Stripe Hog Systems

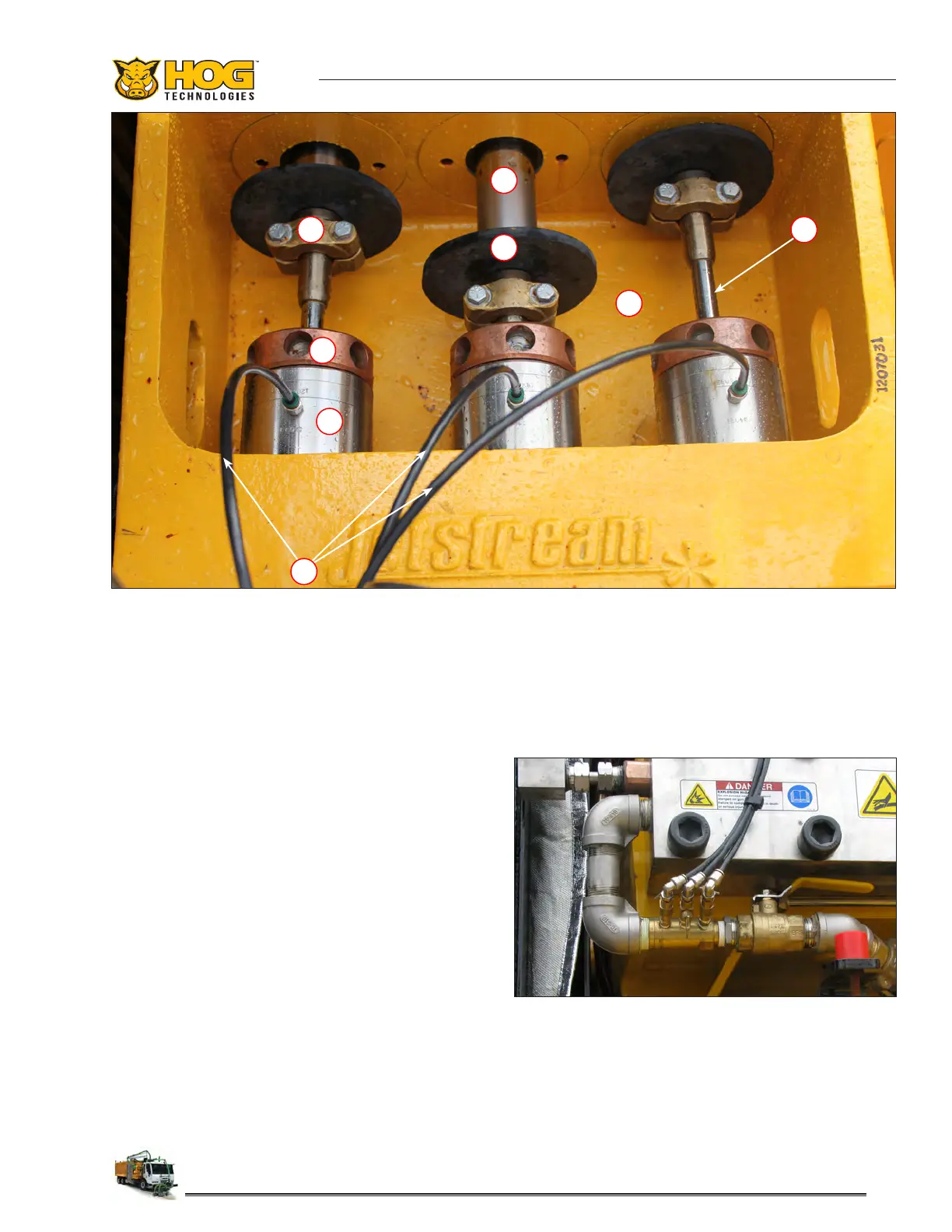

1. Coupling 5. Gland Nut

2. Pony Rod (Connecting Rod) 6. Stung Box

3. Deector 7. Lubrication Lines

4. Plunger 8. Bilge

UHP Pump Bilge & Bilge Compartment Components

1 4

3

2

6

7

5

8

Packing Lube Water And Bilge Pump

There are three (3) stung boxes, packing seals

and plungers in the Ultra-high pressure pump

that must be continuously lubricated and cooled

to achieve maximum life expectancy. Lubrication

and cooling water for the plungers and packing

seals is provided by lubrication lines connected to

the charge water supply line just below the ultra-

high pressure pump manifold.

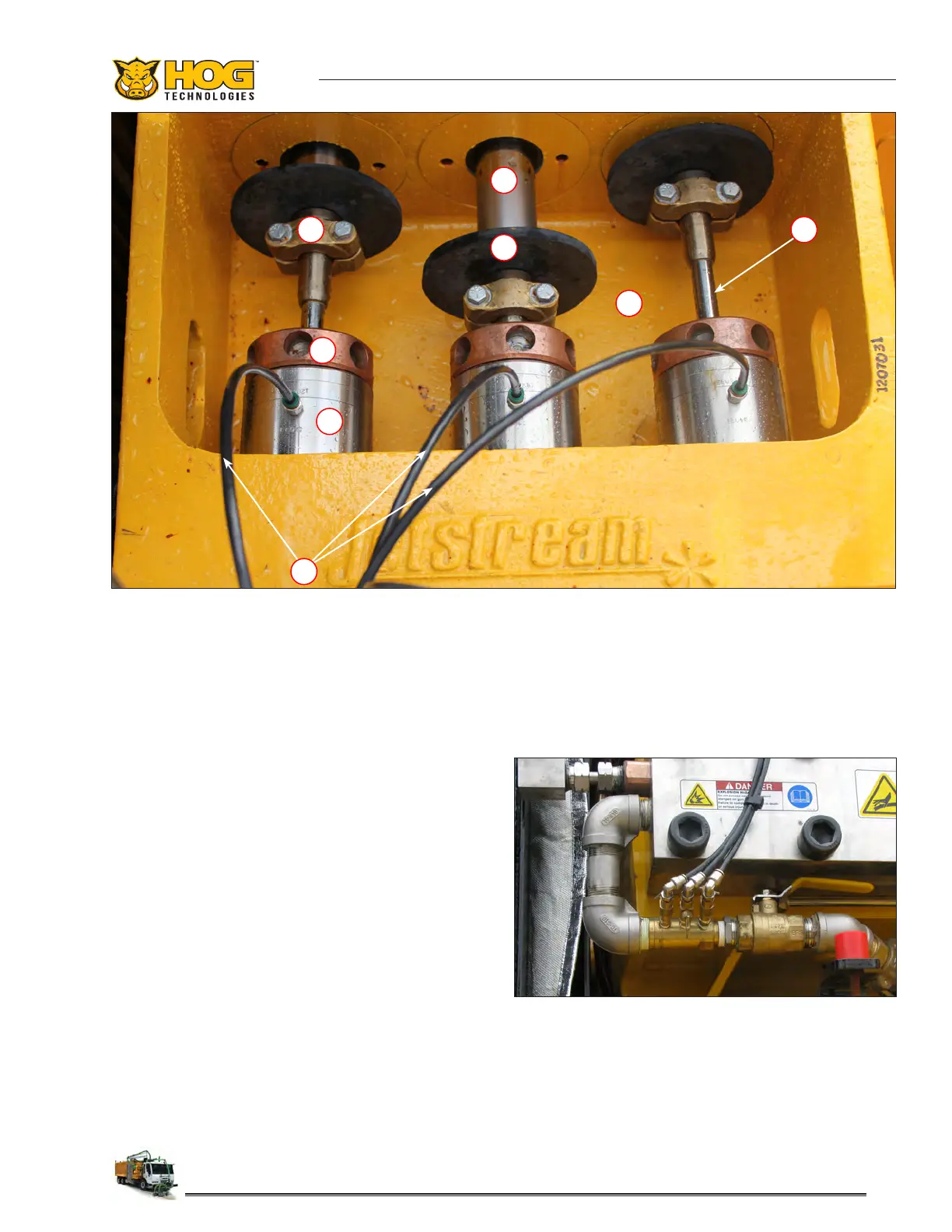

A metering valve on each line controls the ow of

water to the stung box. The ow of water to the

stung box should be checked at the beginning of

each shift and periodically during operation. This

should be done with the PTO engaged, the charge

pump activated and the engine at idle. There

should be a steady ow of water from the back of

each gland nut. Insucient water ow to packing

glands could cause the stung box to overheat

and crack or damage to the packing seals or the

plunger. Packing seals can also be damaged if the

Charge Water Supply Line & Metering Valves

cooling and lubrication line metering valves are

open to wide, allowing excessive water ow to

packing glands. For more information on adjusting

the ow of the lubrication and cooling water refer

to Jetstream Operations manual.

Loading...

Loading...