5050

Stripe Hog Systems

The vacuum lter is a pleated, reusable lter that

is easily accessed through the door on the side

of the canister. Once the lter has been removed

you should de-grease with detergent and power

wash at 2000 psi (138 BAR). A mild solvent solu-

tion may be used to clean thermoplastic or tar

residue from the lter surface. Always check to

ensure there are no damaged areas or holes that

could allow debris to get into the vacuum blower

or silencer. Replace the lter if it is damaged or

shows any sign of deterioration.

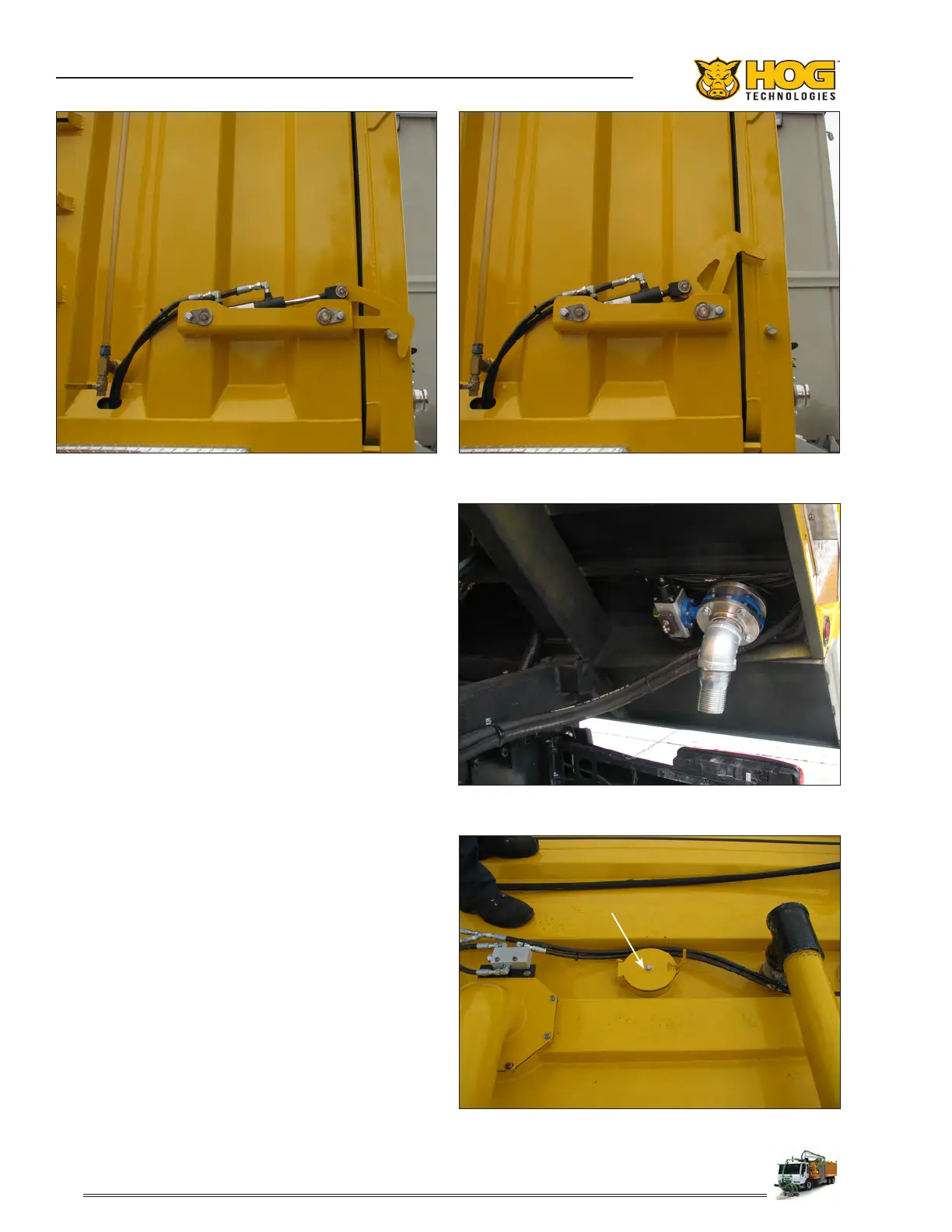

Debris Tank And Debris Bag

The debris tank is constructed from stainless steel

panels. The debris tank door has a hydraulic lock-

ing system, a watertight inatable door seal and

hydraulic cylinders that open and close the door.

Water is drained from the tank prior to dumping

by two pneumatically activated drain valves in the

bottom the tank near the door. Another manual

ball valve in the door provides drainage in the

event that the main drains fail or become clogged.

The main drains are controlled by a rocker switch

in the debris tank control switch panel or by a

switch in the control console in the cab.

All debris water should be drained from the tank

prior to deating the door seal and opening the

tank door to dump the debris bag. A site tube on

the side of the debris tank indicates the recovered

water level and an inspection port on top of the

debris tank provides access to monitor the solid

Pneumatic Debris Tank Drain Valve

Debris Tank Inspection Port

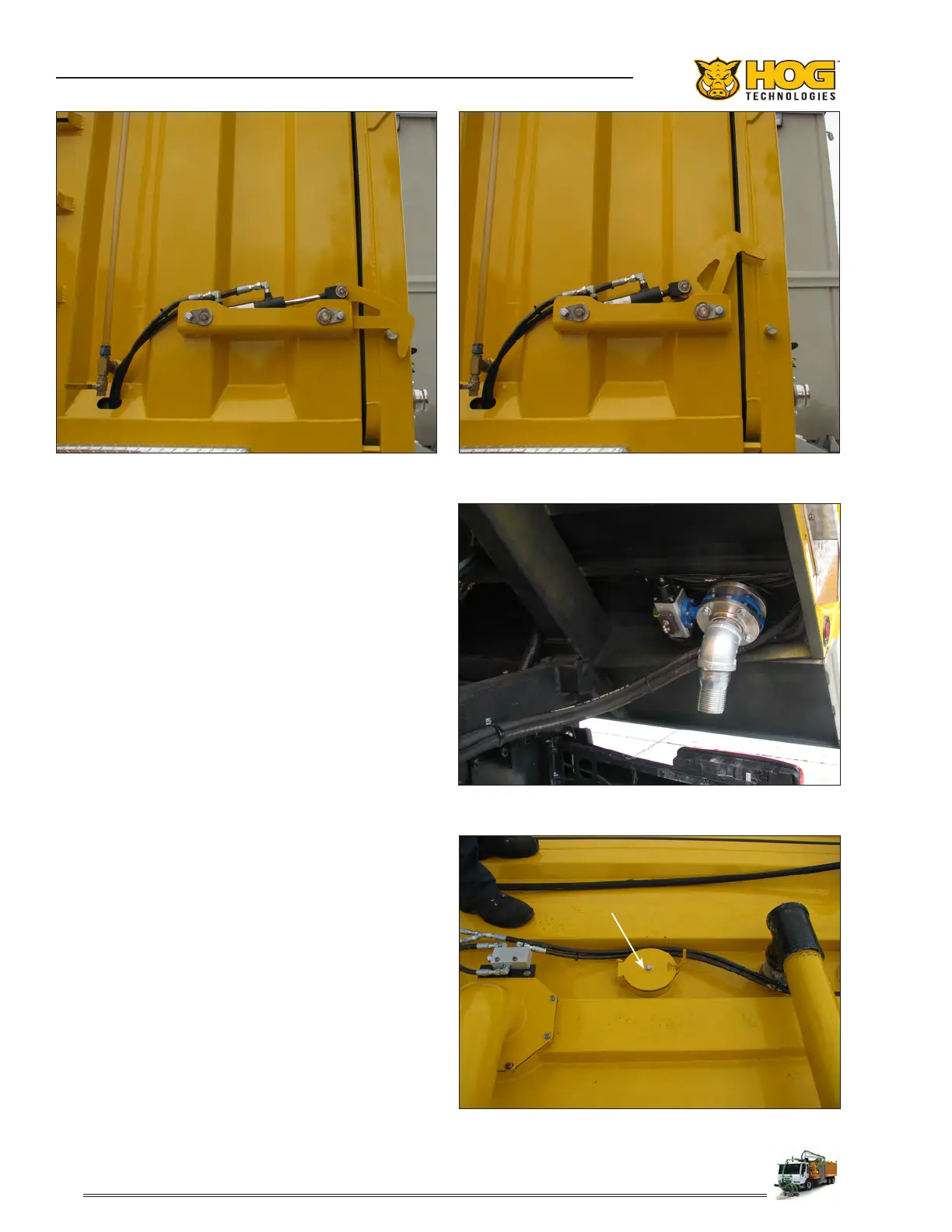

DOOR LATCH

CLOSED

DOOR LATCH

OPEN

Hydraulic Door Latch OpenHydraulic Door Latch Closed

Loading...

Loading...