5656

Stripe Hog Systems

5. Make sure the charge water pump is operating,

then open the clean water supply ball valve

near the pump.

6. Close the charge water supply ball valve to the

Jetstream pump. The valve is located under

the manifold of the Jetstream pump. This will

supply additional water pressure and ow to

the pressure washer pump.

7. Slowly turn the knob on the hydraulic ow

control valve counterclockwise until the bot-

tom edge of the knob is even with the green

ring to activate the hydraulic motor and set

proper RPM for the pump.

8. Monitor pressure to the spray gun with the

pressure gauge on the pump and use the

pressure washer manual bypass valve to set

the desired spray gun pressure. Typical pres-

sure settings range from 2000 psi (138 BAR)

to 4000 psi (476 BAR).

Shutting down the pressure washer:

1. Slowly turn the hydraulic ow control valve

clockwise until it seats in the closed position

to deactivate the hydraulic motor and pres-

sure pump.

2. Slowly close the ball valve on the clean water

supply, then briey pull the trigger on the

spray gun to remove pressure in the hose.

3. Verify 0 pressure on the pressure gauge and

disconnect the pressure hose and gun.

4. Open the charge water supply ball valve to the

Jetstream pump. The valve is located below

the manifold of the Jetstream pump.

5. Reduce engine speed to idle and properly coil

the pressure hose and properly store the hose

and gun in the tool box.

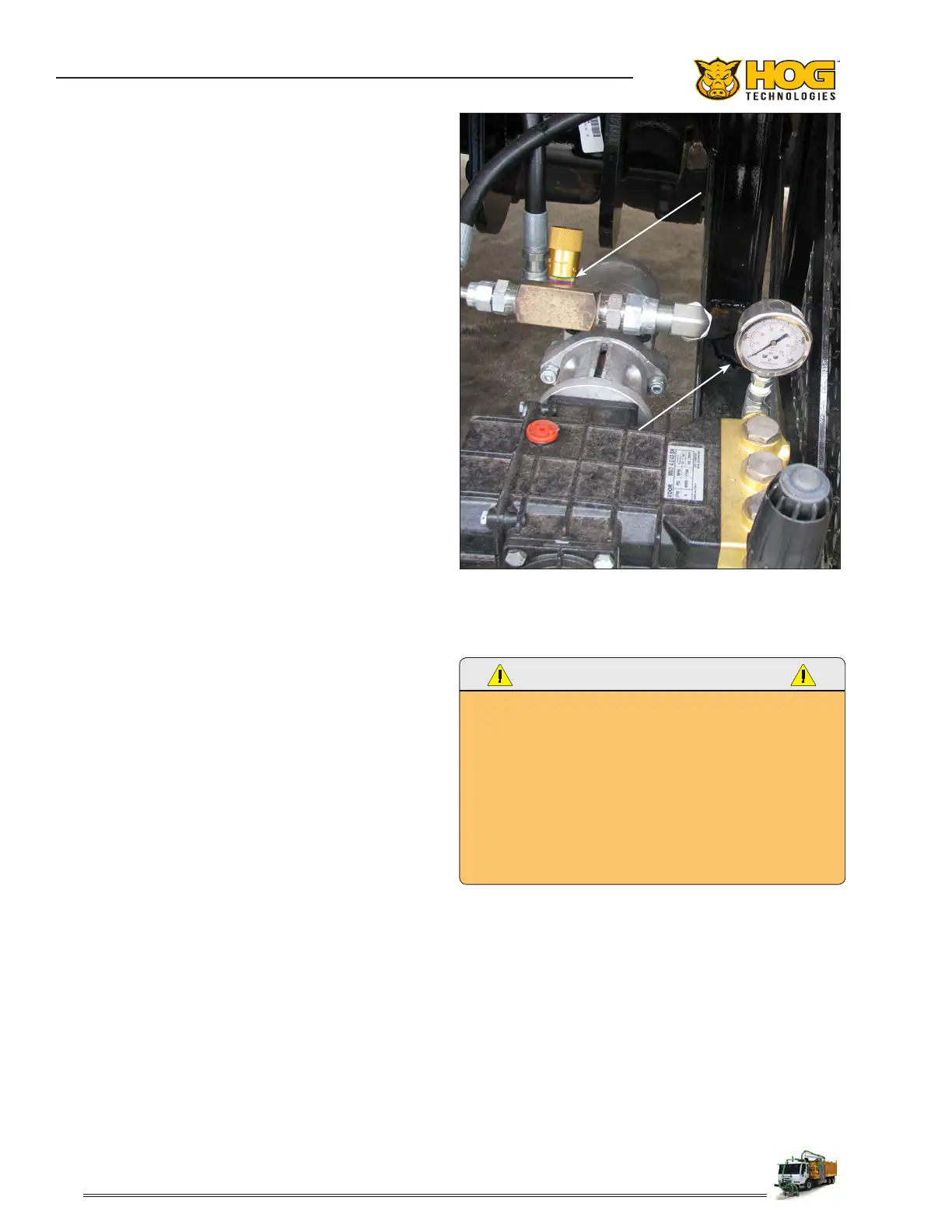

Hydraulic Pressure Valve Set To Green Ring

Water Pressure Gauge

HIGH WATER PRESSURE ESCAPING FROM A DAMAGED OR

DETERIORATED PRESSURE HOSE OR GUN CAN CAUSE

SEVERE INJURY TO PERSONNEL. NEVER OPERATE THE

HANDHELD PRESSURE WASHER WITH A HOSE OR SPRAY

GUN THAT IS DAMAGED OR NOT OPERATING PROPERLY.

ALL HIGH PRESSURE HOSE MAINTENANCE PROCEDURES

AND PRECAUTIONS OUTLINED IN THE HIGH PRESSURE

HOSES, CONNECTIONS AND FITTINGS SECTION OF THIS

CHAPTER APPLY TO THE HANDHELD PRESSURE WASHER

SYSTEM.

Loading...

Loading...