7070

Stripe Hog Systems

NOTICE:

THE HYDRAULIC OIL TEMPERATURE MUST BE ABOVE

60 DEGREES FAHRENHEIT BEFORE OPERATING THE

HYDRAULIC PUMP UNDER LOAD. IF THE OIL TEMPERATURE

IS BELOW 60 DEGREES F (16 C) YOU SHOULD RUN THE

MACHINE IN OPERATE MODE AT IDLE TO CIRCULATE

HYDRAULIC FLUID AT LOW PRESSURE UNTIL IT IS WARMED

TO OPERATING TEMPERATURE AS INDICATED BY THE

THERMOMETER IN THE HYDRAULIC RESERVOIR SIGHT

GAUGE. FAILURE TO DO SO COULD RESULT IN DAMAGE

TO THE INTERNAL SEALS IN THE PUMP.

Hydraulic System Filters

Clean hydraulic uid that has not been exposed to

excessive temperature or become contaminated

is essential to the performance of the system.

As pumps, cylinders and components wear, they

release tiny metal and rubber particles into the

hydraulic uid. These particles act as a grinding

compound as they ow through the system. Or-

dinary dirt and water are common hydraulic uid

contaminants. Any one of these will contribute to

premature failure of hydraulic components. Filters

on the low pressure and high pressure hydraulic

circuits remove these contaminates and increase

the life of the uid and hydraulic components.

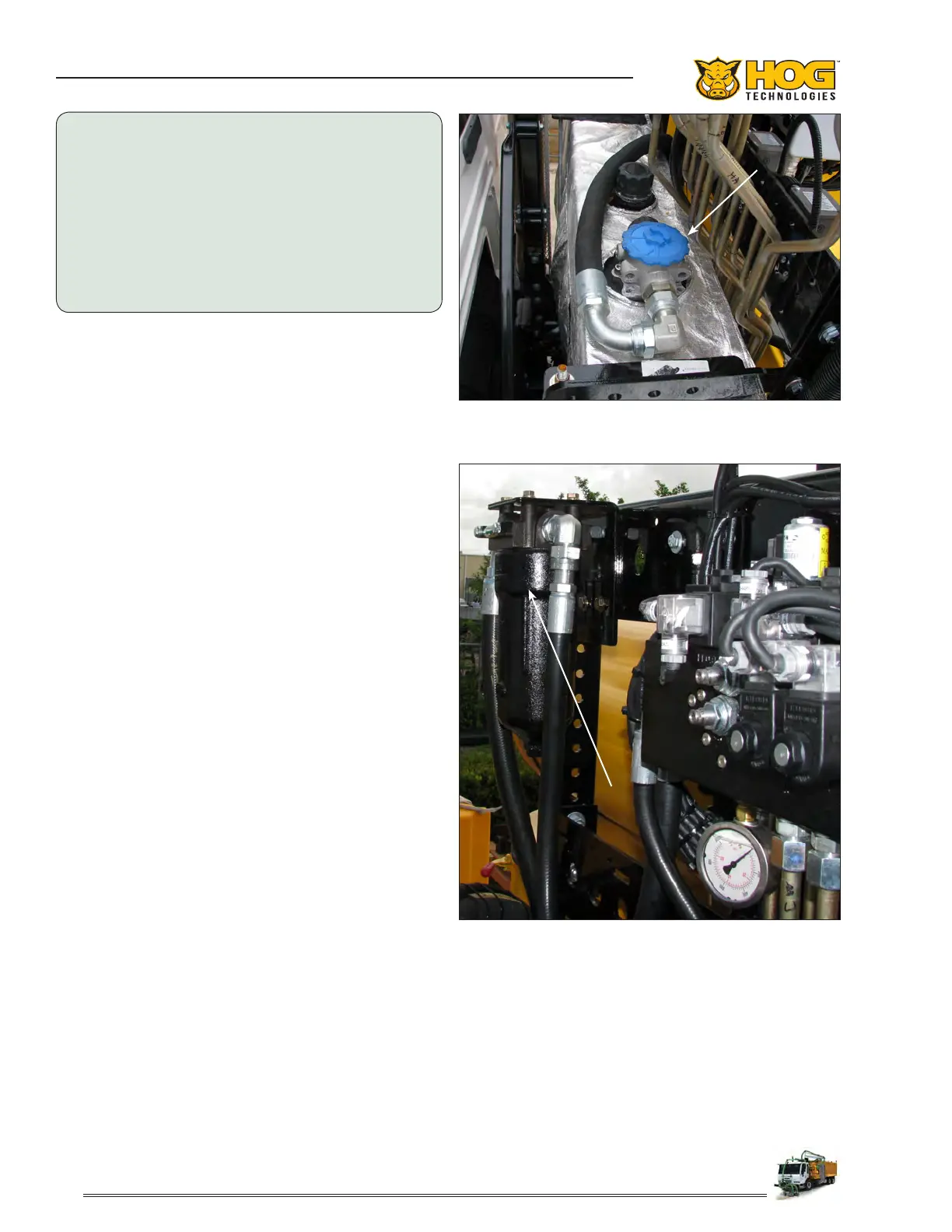

Low Pressure lters

The low pressure lter is a cartridge type lter

on the top of the reservoir tank. All return uid

passes through the low pressure lter as it ows

back into the tank. The lter should be changed

at the same time the hydraulic uid is changed or

if it begins to restrict the return ow.

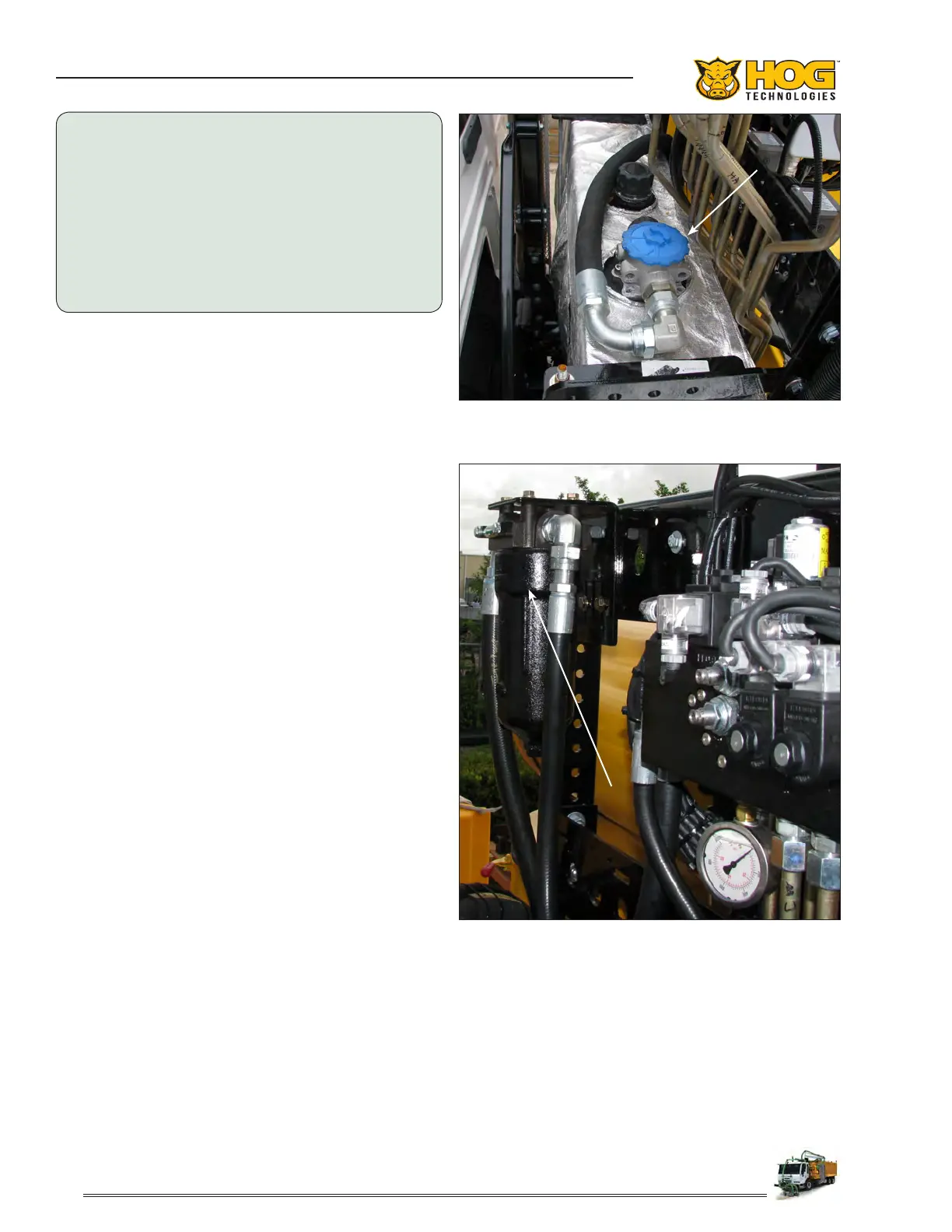

High Pressure Filter

A special ne micron cartridge type lter is located

on the hydraulic tree near the manifold in the high

pressure circuit between the accessory hydraulic

pump and the cylinders, motors and other hydrau-

lic components. The lter removes tiny particles

that could be released by the hydraulic pump.

The lter element is inside a special canister that

can withstand the operating pressure on the high

pressure side of the pump.

A color coded site glass on the top of the lter

housing indicates the condition of the lter ele-

ment and alerts the operator when the element is

dirty and requires changing. Green indicates the

lter element is in good condition, red indicates

Typical Low Pressure Filter

Typical High Pressure Filter

the lter element is becoming clogged and must

be changed. The element should also be changed

when the hydraulic oil is changed.

Loading...

Loading...