AQ252 Universal Injection/Mixing Boiler Reset Control Panels

13 69-1986—02

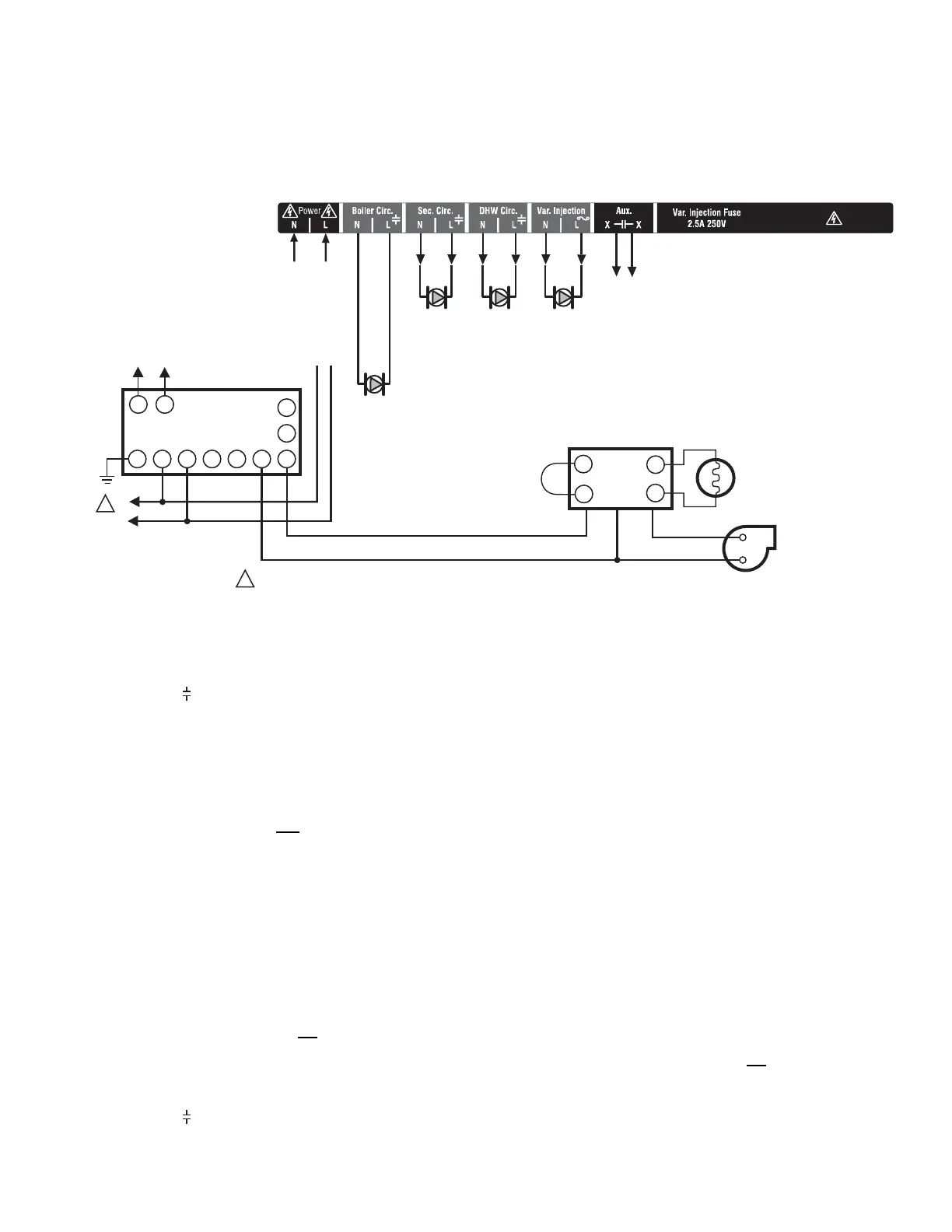

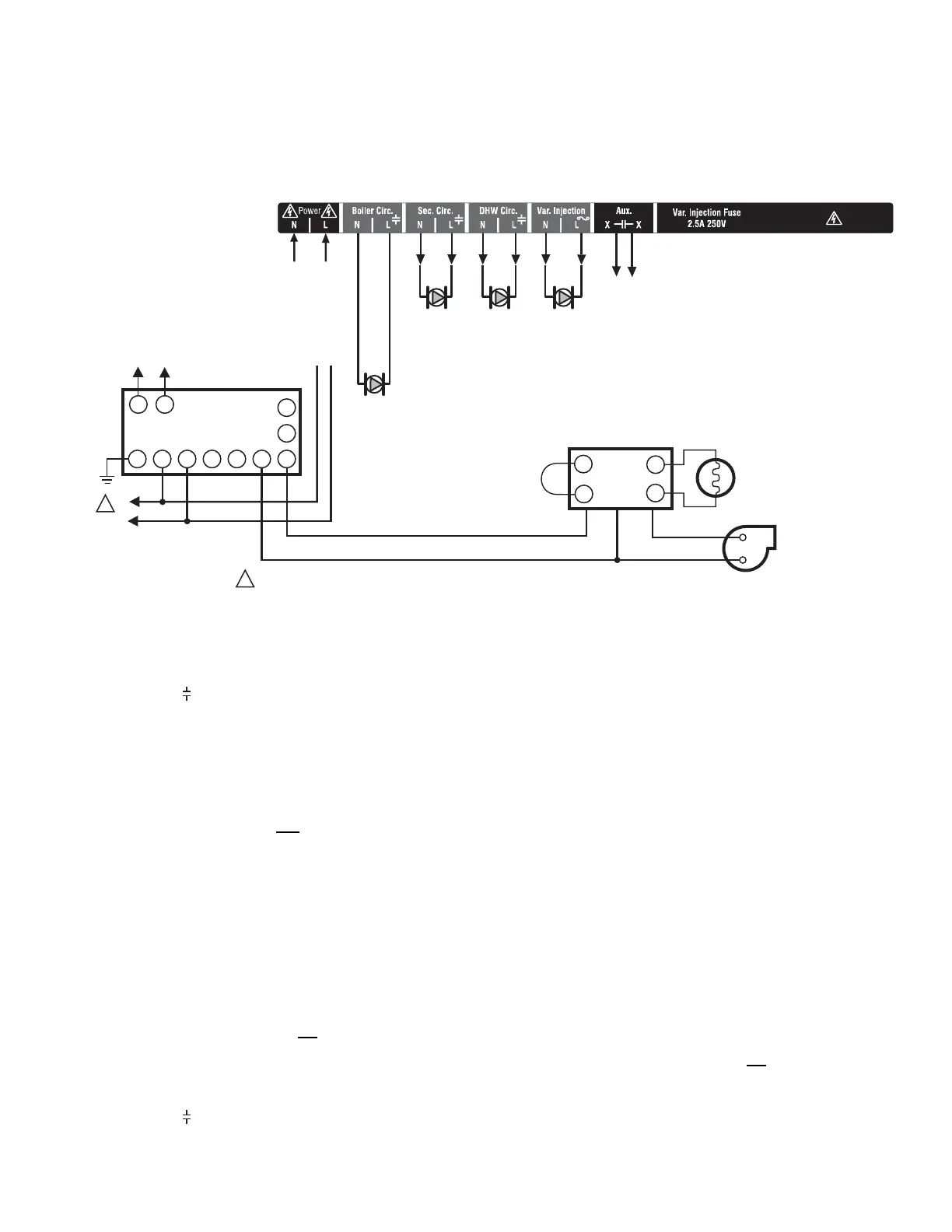

Step 5 – Line Voltage System Outputs

Refer to Fig. 15 and follow these steps to wire the devices to

the AQ252 Control Module.

“1. Boiler Pump”

“2. DHW Device”

“3. Line Voltage Rated Variable Injection Pump”

“4. Line Voltage Rated Aux Output (Aux. Pump)” on page 14

“5. Secondary Pump” on page 14

Fig. 15. Line Voltage Connections for AQ252.

1. Boiler Pump

Connect the N and L wires of the boiler loop pump to the N and

switched hot ( ) terminals of the line voltage Boiler output,

shown in Fig. 17 on page 14. The ground wire of the pump can

be connected to any of the 8 ground screw terminals located

on the back surface of the Control Panel enclosure.

The boiler pump contacts are made after any one of the

following occur:

• A call for heat has occurred from any heating zone.

• The Heat input is shorted on terminals 13 and 14.

• The DHW input is shorted and

the DHW type is configured

as a valve.

The pump is delayed for the FIRE DELAY programmed in the

EQUIPMENT SETUP > BOILER OPERATION sub-menu (see

Fig. 25 on page 41). The boiler pump and the last zone calling

remain “On,” in order to move heat out of the boiler for the

period of time programmed in the Purge time menu under the

fire delay. Manually adjusting thermostats affects the operation

of this software, so it can not be tested manually. You must

observe it under normal operating conditions.

NOTE: If the AQ252 is connected to a modulating

condensing boiler, the boiler pump may need to be

connected to the boiler, not

the AQ252. Confirm this

with the boiler’s installation manual.

2. DHW Device

Wire the DHW pump or line voltage zone valve to the N and

switched hot ( ) terminals of the DHW output, as shown in

Fig. 17 on page 14.

If using a low voltage zone valve, wire the primary of a spud-

mounted transformer (115V to 24V) to the DHW line voltage

contacts and connect the low voltage zone valve to the

secondary terminals of this transformer. A spud-mounted

transformer may be located in one of the conduit knockouts on

the bottom of the AQ252 Control Panel.

Alternatively, a 24 Vac zone valve can be connected to the

Aux. pump line voltage-rated dry contacts, which can be

configured to close on a DHW call. This configuration is

defined in the Installer Equipment Setup menu beginning on

page 32.

The DHW contacts are made when the DHW inputs on

terminals 15 and 16 are shorted by the controlling Aquastat.

This is a line voltage output designed to go to the DHW pump.

If 24 Vac is needed for a low voltage valve, you can mount a

step-down transformer on the conduit opening and wire the

valve from the transformer. When DHW is enabled, the system

has a 30 minute priority over all calls for heat. After 30 minutes,

calls for heat are added back in to the operation for 30 minutes

and then turned off again. This repeats until the DHW is

satisfied.

NOTE: If the AQ252 is connected to a modulating

condensing boiler, the DHW pump will probably need

to be connected to the boiler, not

the AQ252. Confirm

this with the boiler’s installation manual.

3. Line Voltage Rated Variable Injection Pump

The terminals for the variable injection pump are line voltage

rated and protected by an external fuse. A standard pump is

controlled by the output of these terminals.

ZC

ZR

B1

B2

C1

C2

L1

L2

TT

G

L8148, L7148

R8184A, R7184

BURNER AND

IGNITION

C554

F

F

T

T

BLACK

WHITE

ORANGE

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

L1

(HOT)

L2

1

1

TO AUXILIARY DEVICE

(INSTALLER-DEFINED)

BOILER

PUMP

M27692A

N

L

TO LINE VOLTAGE 120V

TERMINALS (N AND L) ON

BOTTOM OF TRANSFORMER

FROM LINE VOLTAGE 120V

TERMINALS (N AND L) ON

BOTTOM OF TRANSFORMER

TO BOILER

TERMINALS 22-23

ON TOP OF AQ15200B

CONTROL MODULE

Loading...

Loading...