BCU 460, BCU 465 · Edition 11.19 15

Application

1.1.8 Flameless mode to reduce NO

x

formation

VAD

BIC..M

IC 40 + BVH

M

VAS..L

VMV

DG

BCU 465..D2

PZL

Process Control (PCC)

AKT

STM

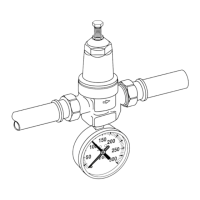

The burner control unit BCU 465 switches the burner

BIC..M ON/OFF in cycles. Burner BIC..M is controlled

without pneumatic air/gas ratio control system. The gas

supply pressure is controlled by the gas pressure regu-

latorVAD; the required burner capacity is set using the

fine-adjusting valveVMV. The capacity is controlled by

actuator IC40 and butterfly valveBVH. An air pressure

switch upstream of the burner monitors the functioning

of the butterfly valve. In addition, air/gas ratio monitor-

ing for the zone or the furnace is required.

As soon as the safety temperature monitor STM signals

a furnace temperature of ≥850°C (1562°F), the burner

can be switched to flameless combustion (Low NO

x

mode) to significantly reduce NO

x

emissions.

Switching to Low NO

x

mode eliminates the counter-

pressure by the flame in the ceramic tubeTSC. At a

constant gas supply pressure, the gas volume increases

by approximately15%. In Low NO

x

mode, the butterfly

valve moves to a smaller open position tailored to the

pressure conditions.

Loading...

Loading...