BCU 460, BCU 465 · Edition 11.19 35

Air control

4.1.2 BCU..F3

VAS VAG

VR..L

V1 V2

UVS

BCU 460

LM..F3

60 61 65

22

µC

81

82

95

96

Process control (PCC)

FCU 500

2

4

A

1

Start

1

3 6

35

P

HT

PLC

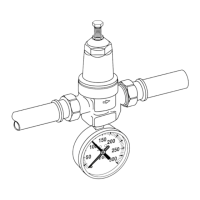

The BCU with LM..F3 activates an air valve for purging,

cooling or starting the burner. The required air capacity

is released by the air valve.

As soon as there is a purge signal at terminal 3 of BCU..

F3, the air valve is activated by the output at terminal

65. The protective system (FCU500) starts the pre-

purge time if there is adequate air flow. After the elapse

of the pre-purge time, the air valve closes for ignition.

Once the protective system (terminal 35, safety inter-

locks) has issued the enable signal, the burner can be

started by the start-up signal at terminal1. The gas

valves for the 1

st

stage are opened and the burner is

ignited (on the BCU..C1 after a successful valve check).

After the operating signal has been received from the

burner, the gas valve for the 2

nd

stage opens.

Staged control

A048 = 0, 1 or 2

Depending on parameters A048 and A049, the con-

trol element may be activated either by the program

or externally via the input at terminal4, see also from

page93 (Air actuator control).

Loading...

Loading...