NFS2-3030 Programming Manual — P/N 52545:K1 03/20/2012 97

NFPA Releasing Applications Releasing Applications

B.2 NFPA Releasing Applications

This control panel can be used for agent release or preaction/deluge control applications. In a

properly configured system with compatible, listed actuating and initiating devices, this control

panel complies with the following NFPA standards for installation in accordance with the

acceptable standard:

Table B.1 NFPA Standards for Releasing Applications

B.3 Abort Switches

The control panel provides for four types of abort switches - ULI, IRI, NYC, and AHJ - each of

which will affect the operation of the delay timer in the releasing zone. For example, an NYC Abort

Switch for releasing zone ZR05 affects only the delay timer in ZR05.

When an initiating device activates, pressi

ng and holding the abort switch will prevent the control

panel from sending the command to dump releasing agents when the Delay Time expires.

Requirements for using an abort switch include

the following:

• A monitor module must be connected to a UL-listed abort st

ation, such as the NBG-12LRA

shown below.

• The monitor module must be programmed with the Type Code

ABORT SWITCH.

• An abort switch shall not be used with a preaction system.

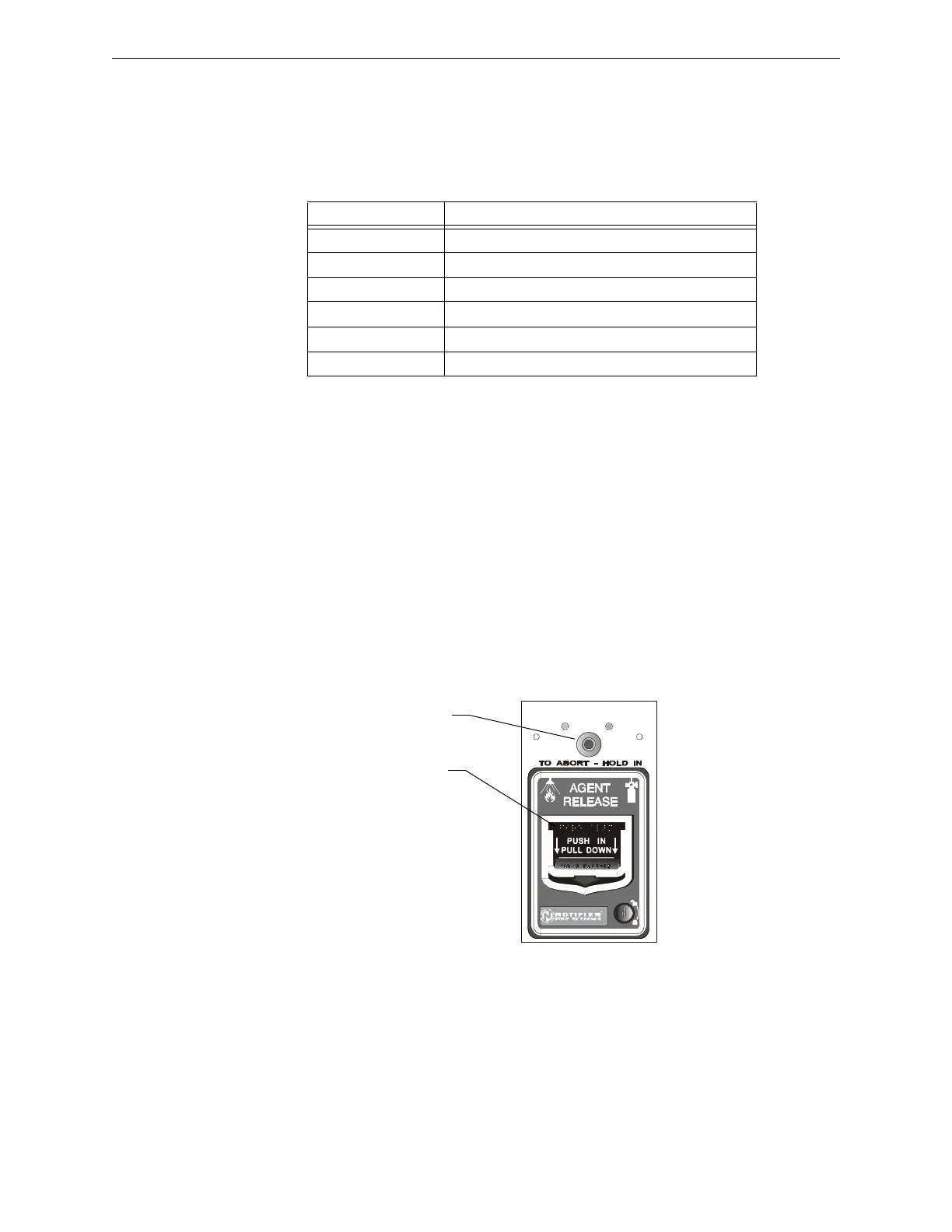

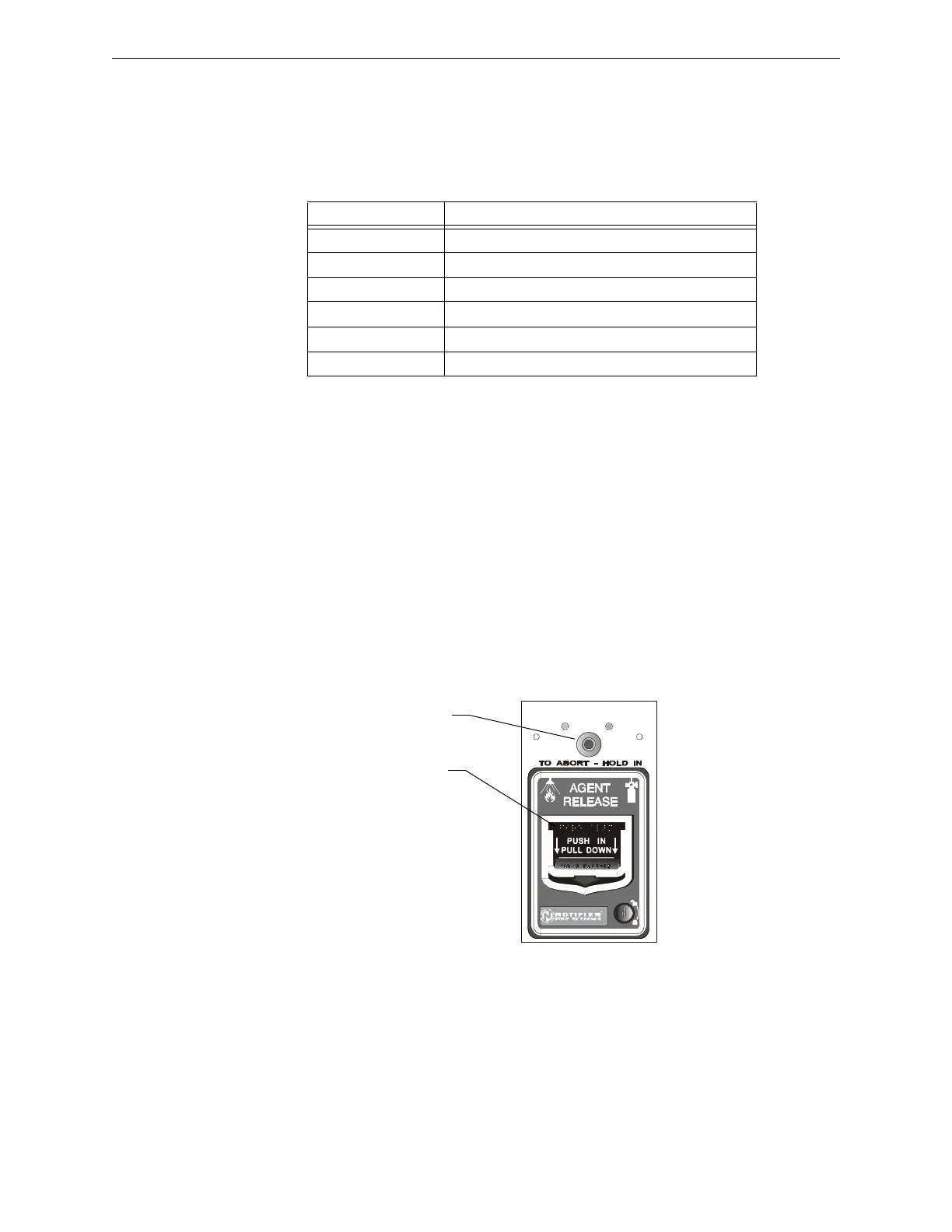

Figure B.1 UL-listed Abort Station

This section contains information

o

n each type of abort switch.

Example of an Abort Switch Application

The figure below contains an illustration for an abort switch

application configuration using

releasing zone ZR05 as an example. The configuration includes:

Standard Covers

NFPA 13 Sprinkler Systems

NFPA 15 Water Spray Systems

NFPA 16 Foam-water Deluge and Foam-water Spray Systems

NFPA 17 Dry Chemical Extinguishing Systems

NFPA 17A Wet Chemical Extinguishing Systems

NFPA 2001 Clean Agent Fire Extinguishing Systems

Abort Switch

Manual Agent

Release lever

CTIVATED

NBG-12LRA station with Abort Switch

Loading...

Loading...