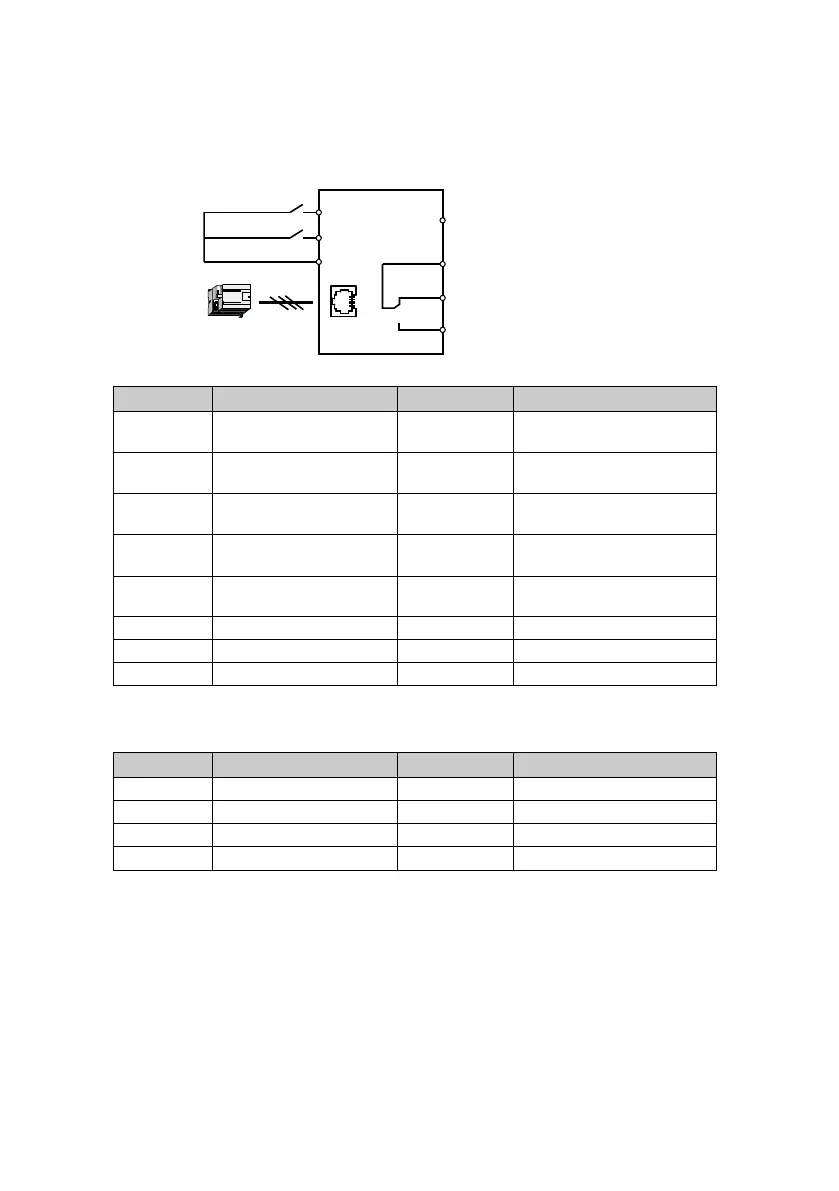

Control the start/stop via terminals and set the running frequency via communication

1. The terminal DI1 is forward running signal input, and DI2 is reverse running signal input, their

wirings are as following figure.

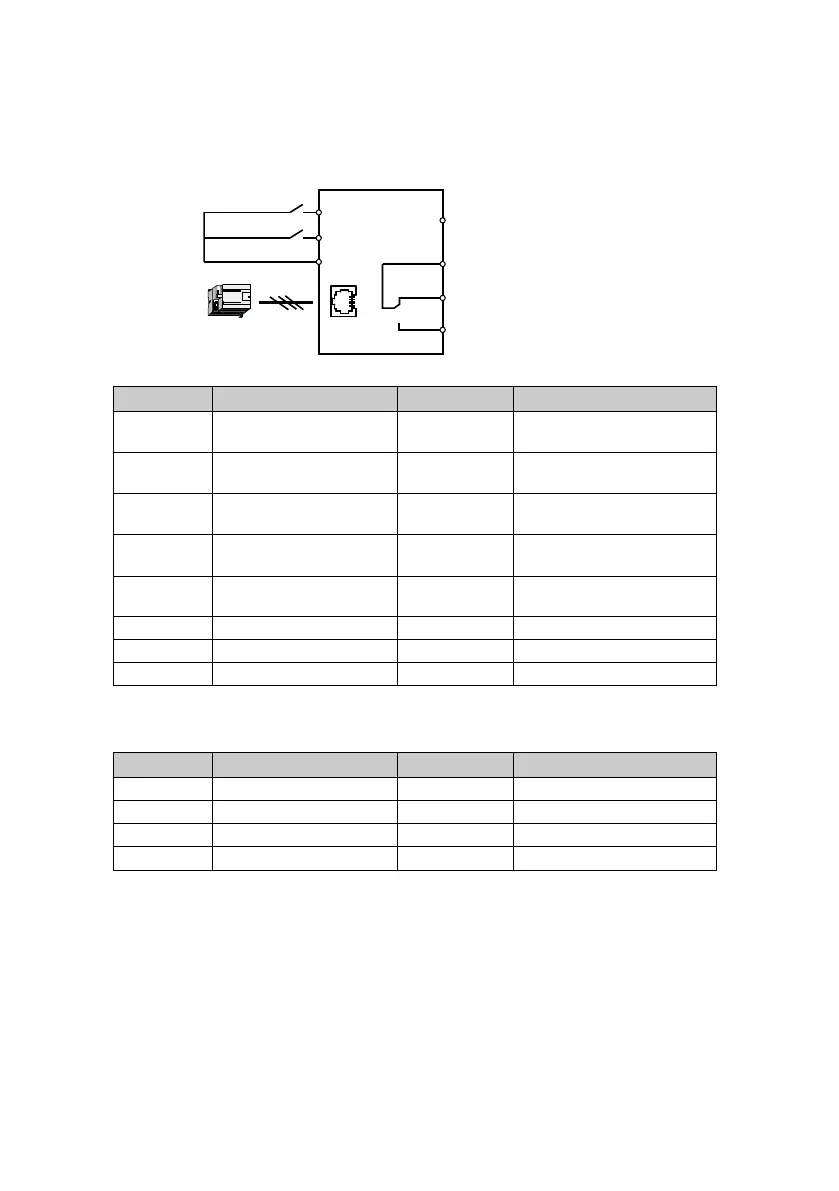

2. After power on, set the functional parameters in accordance with wirings, as following table.

No. Parameter name Setting value Meaning

F00.10

Frequency setting source

selection

2 SCI communication setting

F00.11

Command setting source

selection

1

Terminal running command

source

F15.00

DI1 terminal function

selection

2 (factory setting)

Forward running function

(terminal forward signal input)

F15.01

DI2 terminal function

selection

3 (factory setting)

Rervese running function

(terminal rervese signal input)

F15.18

DO1 terminal function

selection

2 (factory setting) Inverter is running

F17.00 Data format 0 (factory setting) 1-8-2 format, no parity, RTU

F17.01 Baud rate 3 (factory setting) 9600bps

F17.02 Local address 2 (factory setting)

3. Set motor parameters (see motor nameplate parameters) and acceleration/deceleration time

via the display panel, as following table.

No. Parameter name No. Parameter name

F08.00 Rated power of motor 1 F08.04 Rated RPM of motor 1

F08.01 Rated voltage of motor 1

F08.02 Rated current of motor 1 F03.01 Acceleration time 1

F08.03 Rated frequency of motor 1 F03.02 Deceleration time 1

4. Close the K1 of the wiring diagram, the motor will run forward; close K2, run reverse;

simultaneously close or disconnect, the motor will stop.

DI1

COM

K1

K2

Forward terminal

DI2

Reverse terminal

DO1

R1A

R1C

R1B

Fault indication normally closed contact

Output indicating signal at running

Fault indication normally open contact

Common terminal

1

2

34 5 6 7 8

RJ4 5

MODBUS

communication

SCI communication

terminal

Loading...

Loading...