8 Replacing components

110

HSD S.p.A. © - 0108h02a.fm100713

8.4.10 Regulating S4 using the kit

After having replaced the sensor as described in paragraph 8.4, calibrate it as follows:

1. for models E40 - F50 use the 11.32 mm gauge and the 0.04 mm thickness spacer

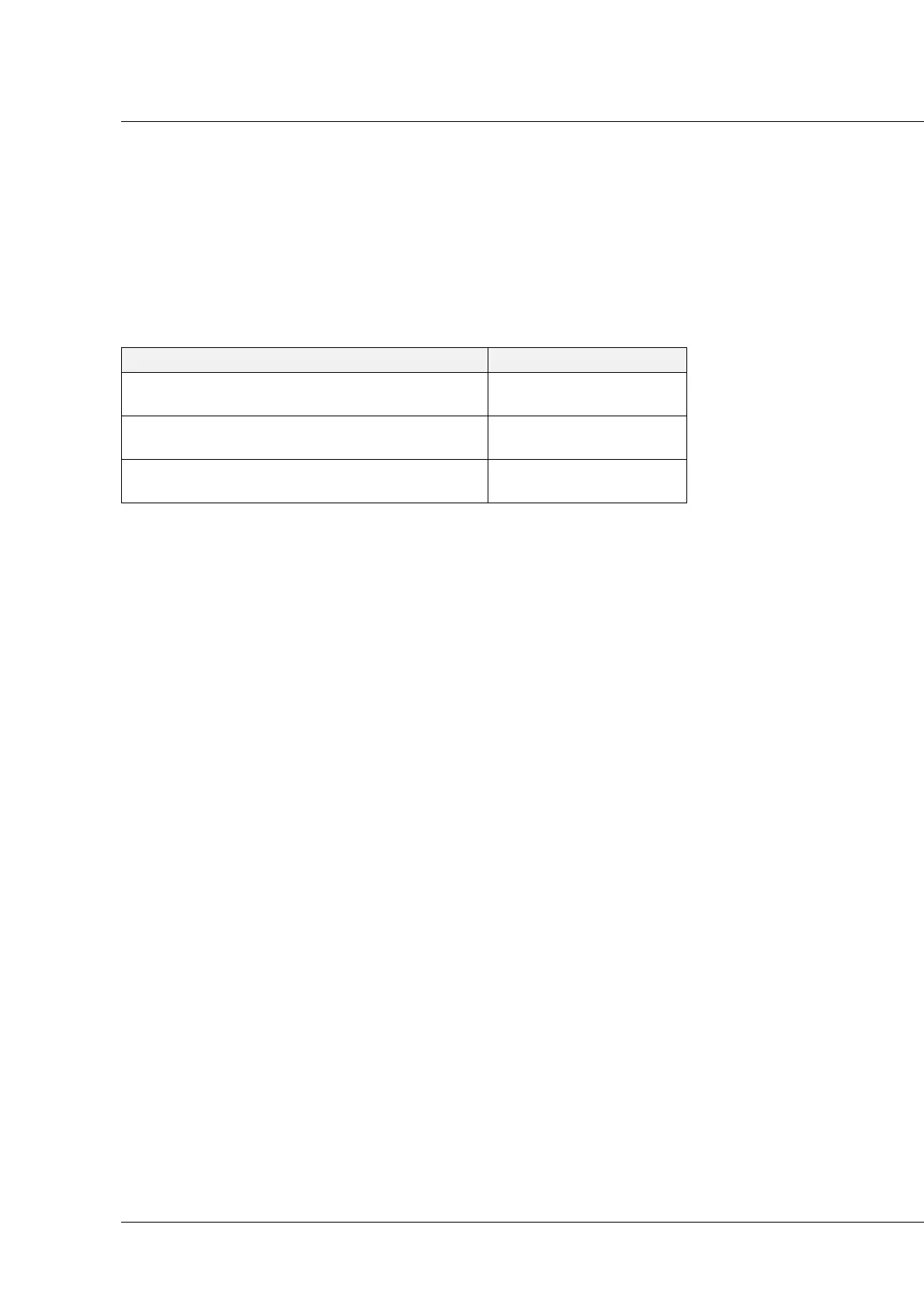

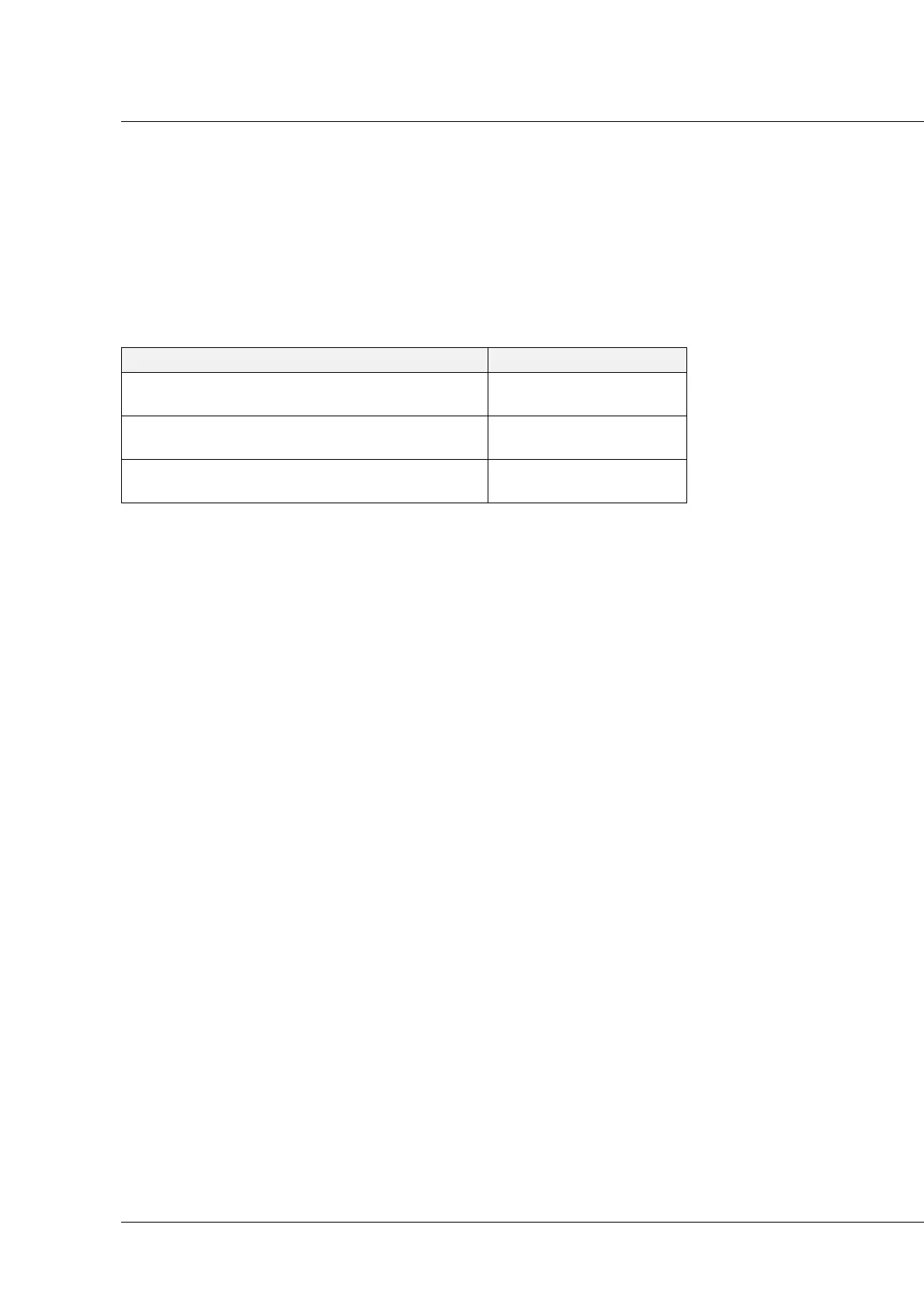

2. Use the gauges and spacers as shown in figures 25 and 26 and check that the signal from

sensor S4 corresponds to that indicated in the following table:

3. Rotate the shaft manually and check that the table is verified for the entire 360° rotation.

4. if not, rotate the sensor until the position necessary to obtain the output described in the table

is found;

5. Fully tighten screw “2”;

6. perform a cycle of 10 tool changes;

7. at the end of the cycle, check that the table shown in point (2) has been satisfied for the entire

360° rotation of the shaft. Otherwise repeat the procedure from the start;

8. if the table is verified, make the machine perform a cycle of 100 tool changes, using the largest

possible number of different tool holders;

9. at the end of the cycle, check that the table shown in point (2) has been satisfied for the entire

360° rotation of the shaft. Otherwise repeat the procedure from the start;

10. if the table in point (2) is satisfied, the calibration of S4 is complete.

8.4.11 Adjusting sensor S3

After having replaced the sensor as described in paragraph 8.4, calibrate it as follows:

1. verify that the signal provided by the sensor corresponds to that described in section 6.8.7;

2. if not, rotate the sensor until the position necessary to obtain the output described in the table

is found 6.8.7;

3. fully tighten the screw “2”.

CONDITION OUTPUT S4

Gauge locked

0.04 mm

ON

Gauge locked

NONE

OFF

Collet open

(tool holder ejected)

OFF

Loading...

Loading...