29

LP-542 REV. 7.16.15

C. GAS CONNECTION REQUIREMENTS

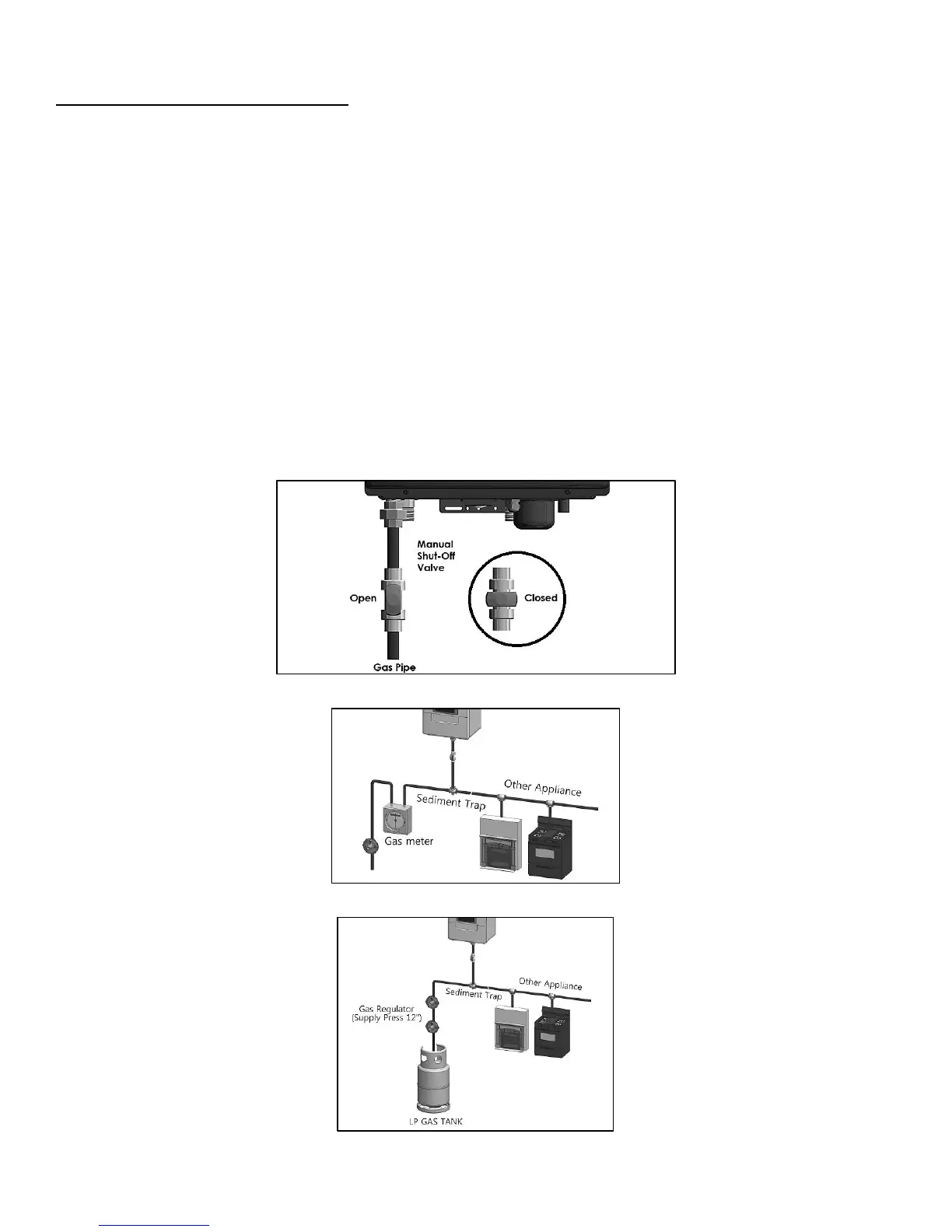

1. The gas connection fitting on the boiler is ¾” male NPT. NOTE: The pipe size must not be less than ½”.

2. The supply line must be sized for the maximum output of the boiler being installed. If there are additional gas boilers from the main

supply line, measure the size of the supply line according to the COMBINED total maximum BTUH draw for the boilers as if they were

operating at the same time.

3. Measure the length of the gas supply line from the gas meter to the boiler. Boiler must be installed downstream of the gas meter to

ensure adequate gas supply. Use the tables in this manual or refer to the gas line manufacturer’s sizing information to determine the

correct supply pipe size.

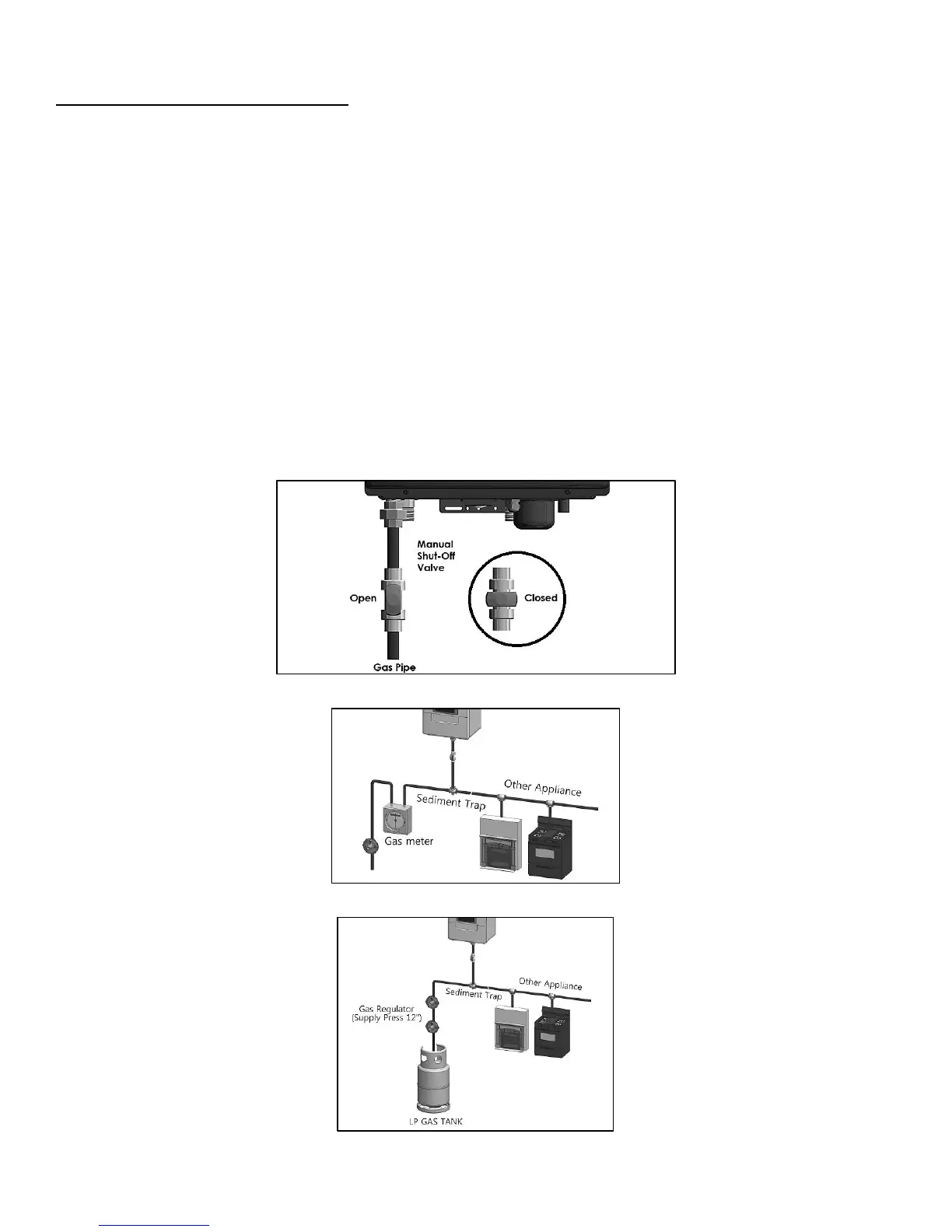

4. A manual gas shut-off valve should be installed in the gas supply line close to the boiler. See Figure 16 for detail.

5. To facilitate any future maintenance, it is also recommended that an approved gas union fitting be installed in the supply line between

the shut-off valve and the connection on the boiler.

6. Test the gas pressure to make sure it meets the minimum standards and does not exceed the maximum standards of the boiler.

7. Leak test the gas line pipe before placing the boiler in operation. Only use approved leak detector liquid solutions to check for leaks.

8. Do not operate the boiler until all connections have been completed and the heat exchanger is filled with water.

10. When using flexible gas lines, ensure that the pipe’s inner diameter and connector is sufficient to supply the required BTUs. Also,

ensure that the flexible line has no crimps or tight bends in it, as this will restrict gas flows.

Figure 16 – Gas Line with Shut-Off Valve Detail

Figure 17 – Natural Gas Piping Installation – NOTE: Capacity to be Not Less than Total Capacity of Connected Boilers

Figure 18 – LP Gas Piping Installation – NOTE: Capacity to be Not Less than Total Capacity of Connected Boilers

Loading...

Loading...