18

LP-542 REV. 7.16.15

Failure to follow all instructions can result in flue gas spillage and carbon

monoxide emissions, causing severe personal injury or death.

When removing an existing boiler, the following steps must be followed.

1. Seal any unused openings in the common venting system.

2. Visually inspect the venting system for proper size and horizontal pitch

to determine if there is blockage, leakage, corrosion or other deficiencies

that could cause an unsafe condition.

3. If practical, close all building doors, windows and all doors between the

common venting system and other spaces in the building. Turn on clothes

dryers and any boilers not connected to the common venting system. Turn

on any exhaust fans, such as range hoods and bathroom exhausts, at

maximum speed. Do not operate a summer exhaust fan. Close all fireplace

dampers.

4. Place in operation the boiler being inspected. Follow the lighting

instructions. Adjust the thermostat so the boiler will operate continuously.

5. Test for spillage at the draft hood relief opening after 5 minutes of main

burner operation. Use the flame of a match or candle or smoke from a

cigarette.

6. After it has been determined that each boiler remaining connected to common venting system properly vents when tested as

outlined, return doors, windows, exhaust fans, fireplace dampers and any other gas burning boiler to their previous condition of use.

7. Any improper operation of the common venting system should be corrected so the installation conforms to the National Fuel Gas

Code, ANSI Z223.1. When resizing any portion of the common venting system, the common venting system should be resized to

approach the minimum size as determined using the appropriate tables in Appendix G in the National Fuel Gas Code, ANSI Z 223.1.

I. WALL-MOUNTING THE BOILER

The boiler must be installed on a wall that can bear its weight (more than 110 lbs. when fully plumbed and full of water). Installing the

boiler on a wall which cannot support its weight could result in property damage, personal injury, or death.

The boiler may be installed on any suitable internal wall (suitable sound-proofing may be required when installing onto a stud partition

wall).

This boiler is too heavy for one person to lift. It is highly recommended to install the boiler with two people. Use caution as to not drop

the boiler, which could damage the boiler and cause property damage and/or severe personal injury. Verify that the boiler is properly

and securely mounted before leaving unsupervised. Failure to comply with the above and properly mount the boiler could result in

substantial property damage, severe personal injury, or death.

This wall mounting system is not seismic rated and should not be applied as such. Failure to comply with the above and properly mount

the boiler could result in substantial property damage, severe personal injury, or death.

POSITIONING THE BOILER ON THE WALL

1. Attach the wall bracket on the location where you want to install the boiler. Ensure it is level and on stud (16” centers) before

proceeding.

2. Mark the four drill holes with a pencil or marker. Remove the wall bracket.

3. Drill four (4) holes using a 5/32 drill bit at the marked hole locations.

4. Mount the wall bracket to the wall with the four (4) included anchor bolts. Ensure the mounted bracket is level. See Figure 5A.

5. Align the boiler bracket grooves on the back of the boiler with the tongues on the wall bracket and hang the boiler on the

bracket. See Figure 5B.

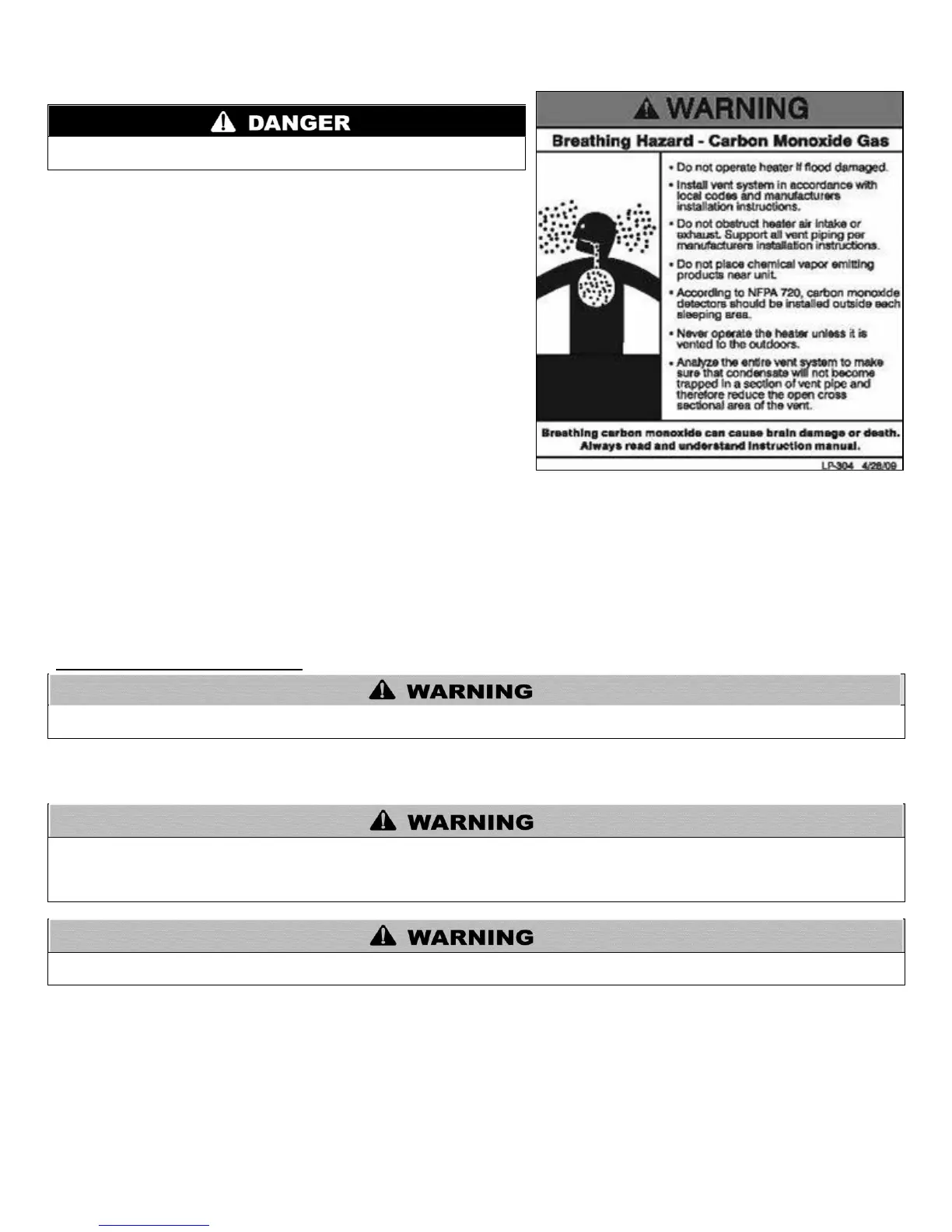

Figure 4 - CO Warning Label

Loading...

Loading...