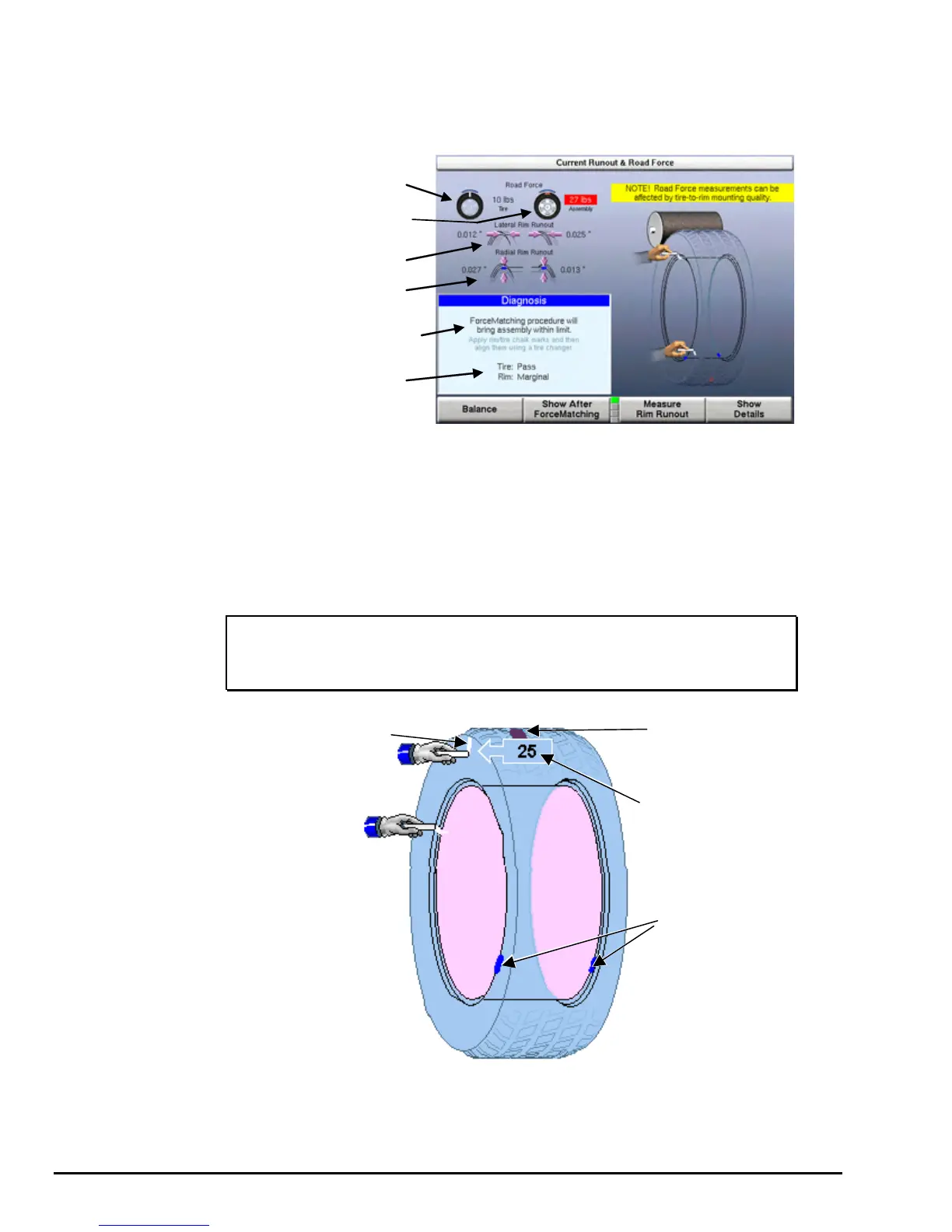

If the wheel assembly can be corrected by using Forcematch®, the diagnosis box will

display “Forcematching procedure will bring assembly within limits” and the

components will be listed as “Pass,” “Marginal,” or “Limit Exceeded.” If non-first

harmonic component limits are exceeded, the “Diagnosis Explanation” popup screen

will automatically appear. Refer to “Diagnosis Explanation Screen,” page 102.

TIRE ROAD FORCE

MEASUREMENT

LATERAL RIM RUNOUT

MEASUREMENT

ASSEMBLY ROAD

FORCE MEASUREMENT

RADIAL RIM RUNOUT

MEASUREMENT

ASSEMBLY DIAGNOSIS

COMPONENT

EVALUATIONS

The “Show After Forcematching” key may be selected to view the estimated road

force that will remain after the Forcematching procedure has been completed.

Forcematch® Procedures

To correct road force by using Forcematch®:

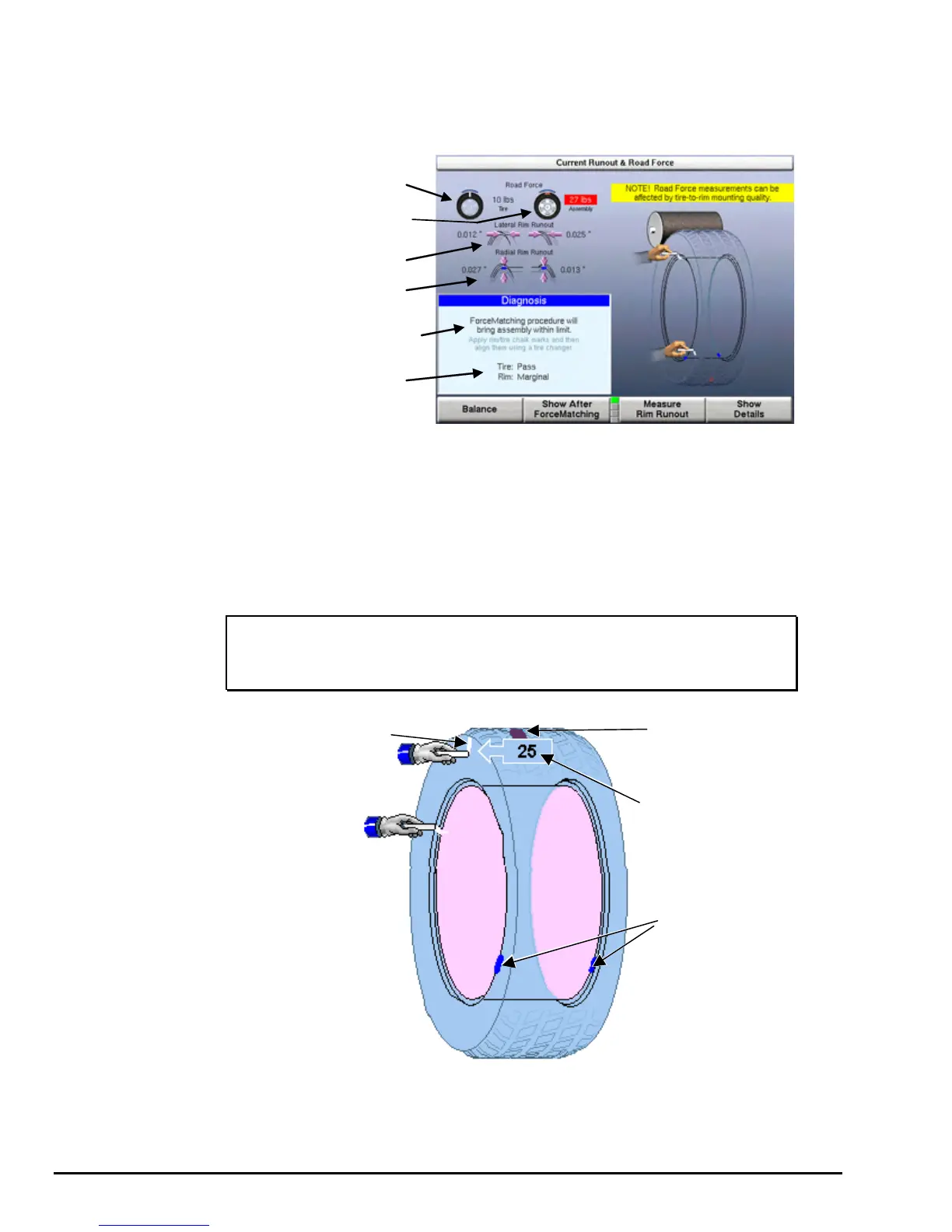

Rotate the tire road force high spot on the wheel to TDC, or with the hood in

the raised position and the servo enabled, press “START.” Mark the tire with

a piece of chalk or a marker at TDC. If desired, mark the tire with the

ForceMatch® Code. Refer to “Using ForceMatch Codes Feature,” page 86.

NOTE: When the wheel is rotated to TDC, the chalk will appear

green on the console display and the tire ForceMatch Code

will appear in the tire tread.

TIRE

FORCE VARIATION

HIGH SPOT MARK

INDIVIDUAL

RIM HIGH SPOTS

TIRE/WHEEL

ASSEMBLY

FORCE VARIATION

HIGH SPOT

TIRE

FORCEMATCH CODE

Rotate the rim low spot on the wheel to TDC, or with the hood in the raised

position and the servo enabled, press “START.” Mark the rim with a piece of

chalk or a marker at TDC. If desired, mark the rim with the ForceMatch Code.

Refer to “Using ForceMatch Codes Feature,” page 86.

84

Road Force® Measurement Procedures GSP9720JLR Wheel Balancer Operation Instructions

Loading...

Loading...