VM Series Maintenance and Safety Manual 704-0212-209 Machine Maintenance 3- 43

If a machine malfunction occurs, then consider the following issues:

• Is another machine that uses high current connected to the AC distribution

power supply line?

• Is the ground impedance of the AC distribution power supply line sufficient?

• Are there fluctuations in the input voltage to the machine?

• Is there a source of “noise” nearby (crane, welder, etc.)?

• If other CNC or NC machines are connected to the same group of circuits, do

any of those machines demonstrate similar problems?

• Was another machine operating at the same time the problem occurred?

• Does the problem occur mainly at a certain time of day?

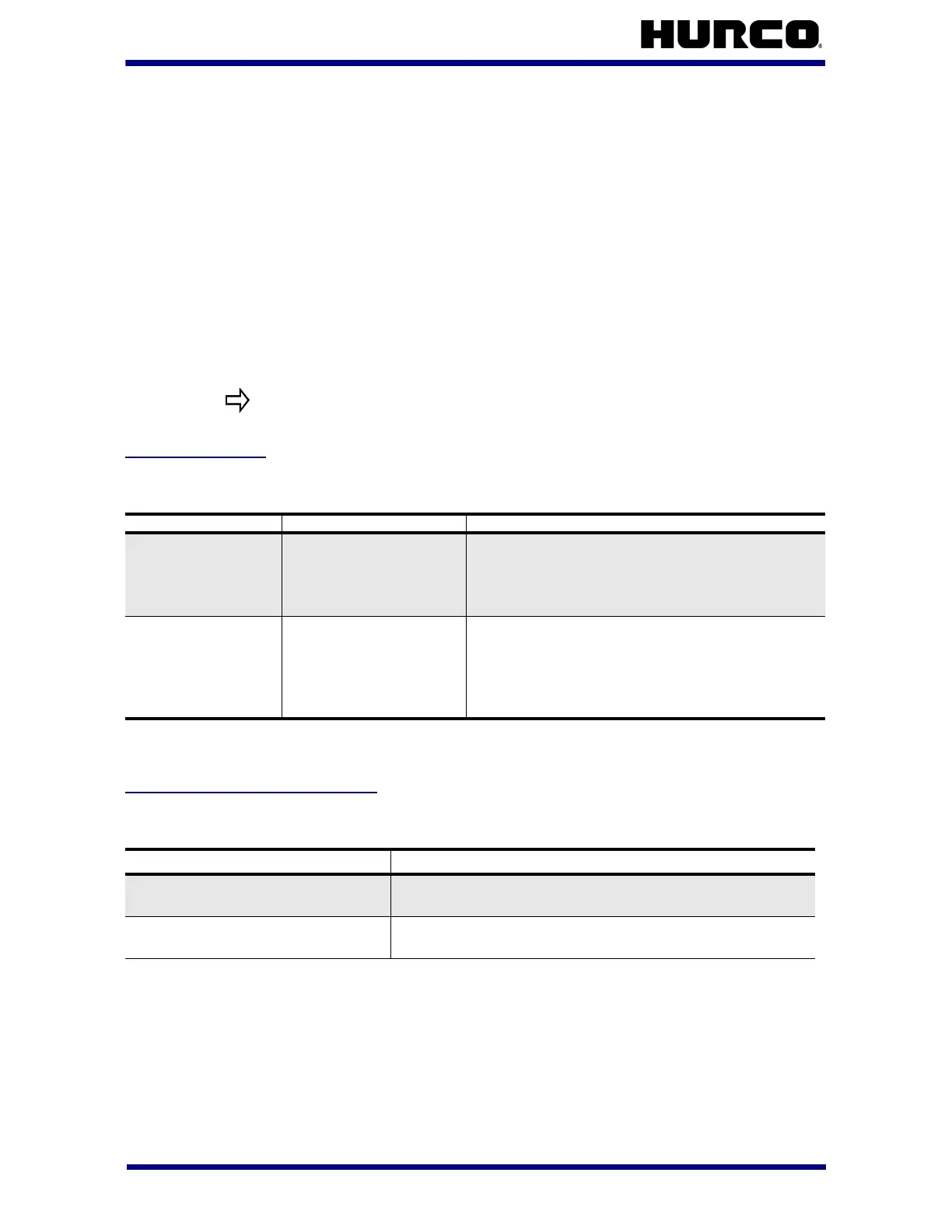

Coolant System

Refer to the table below if a problem occurs with the coolant system.

Table 3–21. Troubleshooting: Coolant System

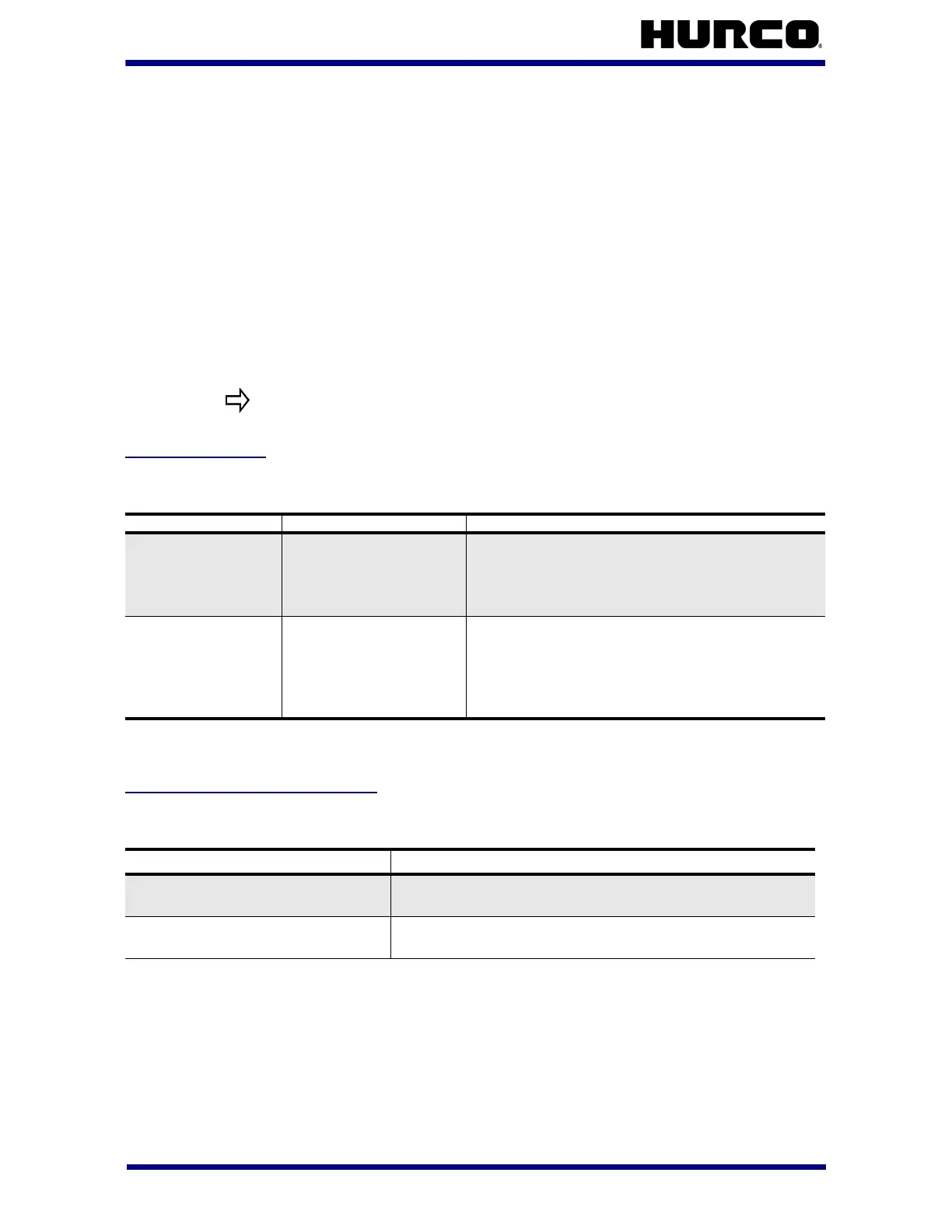

Motion and Spindle Rotation

Refer to the table below if a problem occurs with the spindle unit.

Table 3–22. Troubleshooting: Spindle Unit

Power surges can occur when large loads are suddenly placed on, or

removed from, an electrical system.

Problem Cause Solution

Coolant flows

slowly or stops.

• Clogging due to

dirty coolant.

• Pump is not

working properly.

• Flush lines, clean filters, drain and refill

the system with fresh coolant.

• Check and service the pump. For mist

system, check shop air pressure.

Coolant fails to

start.

• Coolant is not

programmed to be

On.

• Coolant pump not

working.

• Check the operating mode (auto or

manual) or programming.

•Check connector.

Cause Solution

Program might not have proper

RPM setting.

Check the RPM setting in the program. If this setting is

wrong, check and correct the entire program.

Spindle drive breaker is tripped. Power down the machine, reset the breaker on the

spindle amp, and turn on power.

Loading...

Loading...