3 - 6 Machine Maintenance 704-0212-209 VM Series Maintenance and Safety Manual

Autolube System

The Autolube system automatically lubricates the slideways, guideways, and ballscrews.

The preset discharge rate is 3.0 cubic centimeters (cc) per pump cycle. Refer to Adjust

Autolube Discharge Rate, on page 3 - 7 for details. The way lube pressure should be set

at 2.9 bar or 42 psi.

Machining centers use a digital timer Autolube system. When servos are On and

adequate pressure is attained, the system cycles on for 30 seconds to send lube oil

through the machine, then cycles off for 15 minutes. The Autolube system is located on

the back of the machine. Open the machine’s rear access door to access the Autolube

system.

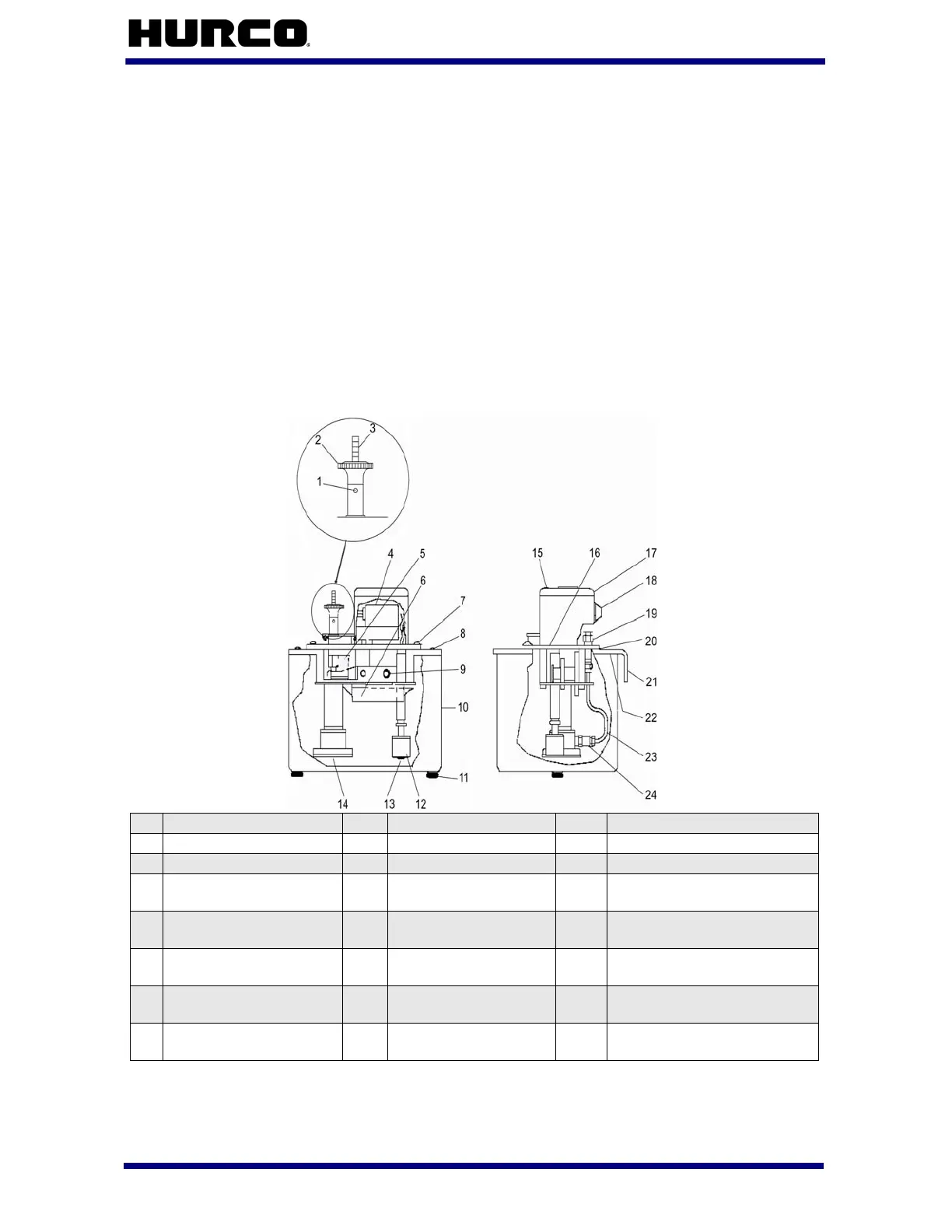

Here is a diagram of a machining center Autolube system:

Figure 3–1. Autolube Pump and Tank Assembly

1

Set screw

9

Retaining ring

17

Motor cover

2

Discharge plunger

10

Reservoir

18

Grommet

3

Indicator rod

11

Screw

19

“Thru” coupling

4

Electric motor

12

Float switch

assembly

20

Reservoir gasket

5

Filter screen

13

O-ring

21

Mounting bracket,

reservoir

6

Reservoir worm and

gear lube

14

Suction filter group

22

Reservoir gasket

7

Screw, cover

mounting

15

Screw, cover

mounting

23

Outlet tube assembly

8

Screw, reservoir

mounting

16

Gasket, motor cover

24

Outlet check valve

assembly

Loading...

Loading...