VM Series Maintenance and Safety Manual 704-0212-209 Machine Maintenance 3- 45

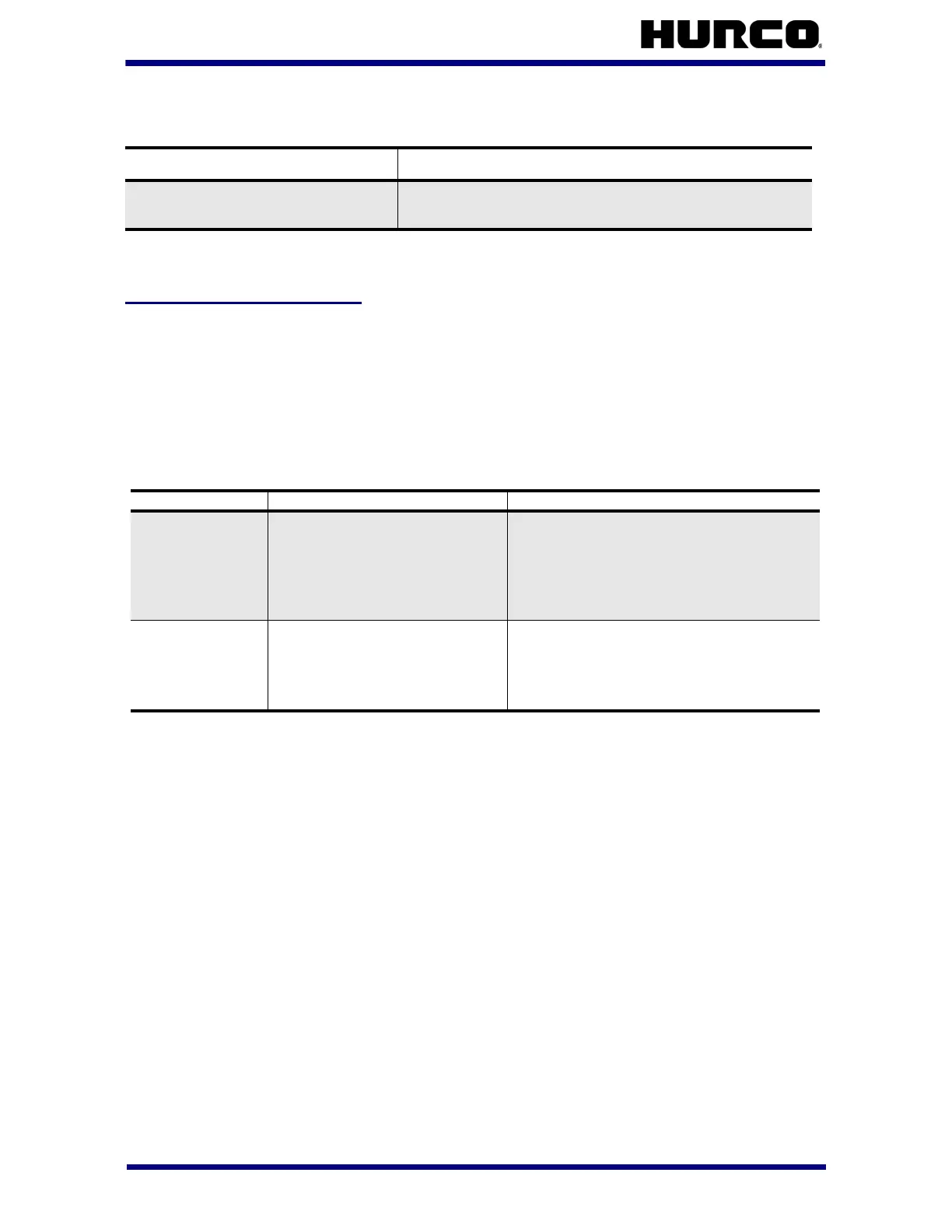

Refer to the table below if small errors in dimensions show up occasionally.

Table 3–25. Troubleshooting: Errors in Dimensions

Environmental Conditions

Temperature and other environmental variables can cause problems that might otherwise

be attributed to the machine.

When the electrical cabinet overheats, control power is disabled and a message appears

on the screen until the cabinet temperature sensor registers a temperature drop to an

acceptable level. If this error condition occurs, make certain the cabinet is not subject to

an additional heat source, such as a space heater or bright sunlight from a nearby

window.

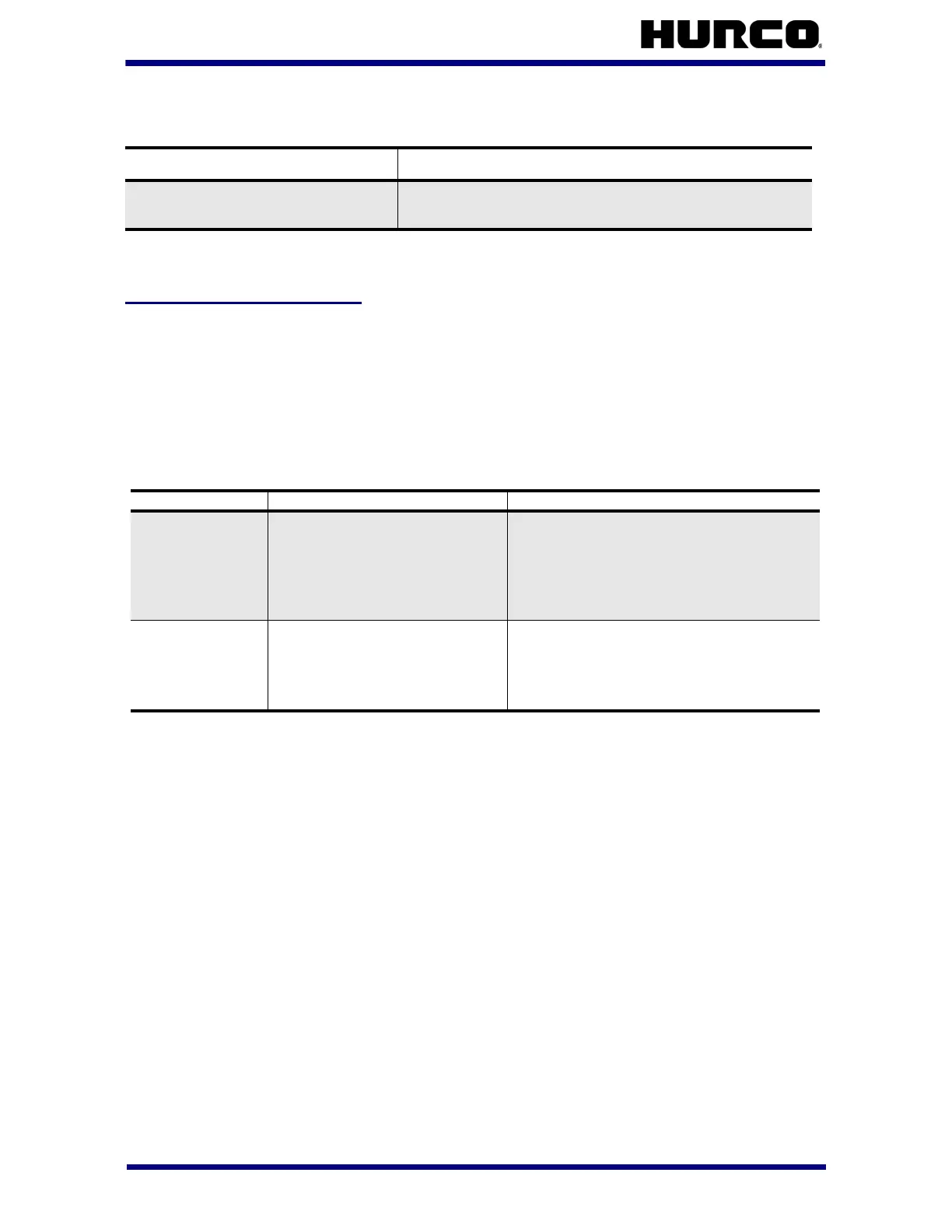

Table 3–26. Troubleshooting: Environmental Factors

Cause Solution

Temperature fluctuates as the

part is machined.

Stabilize the temperature of the blank by providing

enough coolant while machining.

Problems Causes Solutions

Relatively small

dimensional

problems occur

in the product.

Metal blanks stored in

temperatures much higher or

lower than the temperature

of the machining area can

expand or contract during

and after machining.

Before machining, move the blanks to

the machine area and allow the blanks

time to reach ambient temperature.

Dust, debris,

rust or

discoloration

accumulates on

work surfaces.

Extreme temperatures are

typically the problem, and/or

the environment is too humid

or too dusty.

Improve the machine environment. For

example, close the machining area to

outside dust and install air conditioning

to lower room temperature and

humidity levels.

Loading...

Loading...