3 - 36 Machine Maintenance 704-0212-209 VM Series Maintenance and Safety Manual

Spindle Run-in or Cycle Procedure

Monthly: Perform a spindle run-in before operating the machine if the spindle has been

idle for more than 30 days or if the spindle has never been used.

1. Referring to the appropriate Max RPM Spindle table below, run the spindle for

the indicated time, at the recommended speeds, depending on your maximum

spindle speed. Proceed in the order listed in the table.

2. Monitor the temperature at either the front or upper bearing and either the

rear or lower bearing (depending on the type of machine), both of which

should not exceed 55º C (130º F) once the maximum RPM is achieved.

3. If spindle flange temperature does not exceed 55º C (130º F) at any time

during the spindle run-in procedure, then the warm-up procedure is complete.

4. If spindle flange temperature exceeds 55º C (130º F) at any time during the

spindle warm-up, then stop the spindle immediately. Allow the spindle to cool

to room temperature.

5. Restart the warm-up procedure at the last speed used prior to the

temperature spike.

6. Repeat steps 1-3 above until the spindle runs at each specified RPM for the

time specified, below 55º C (130º F).

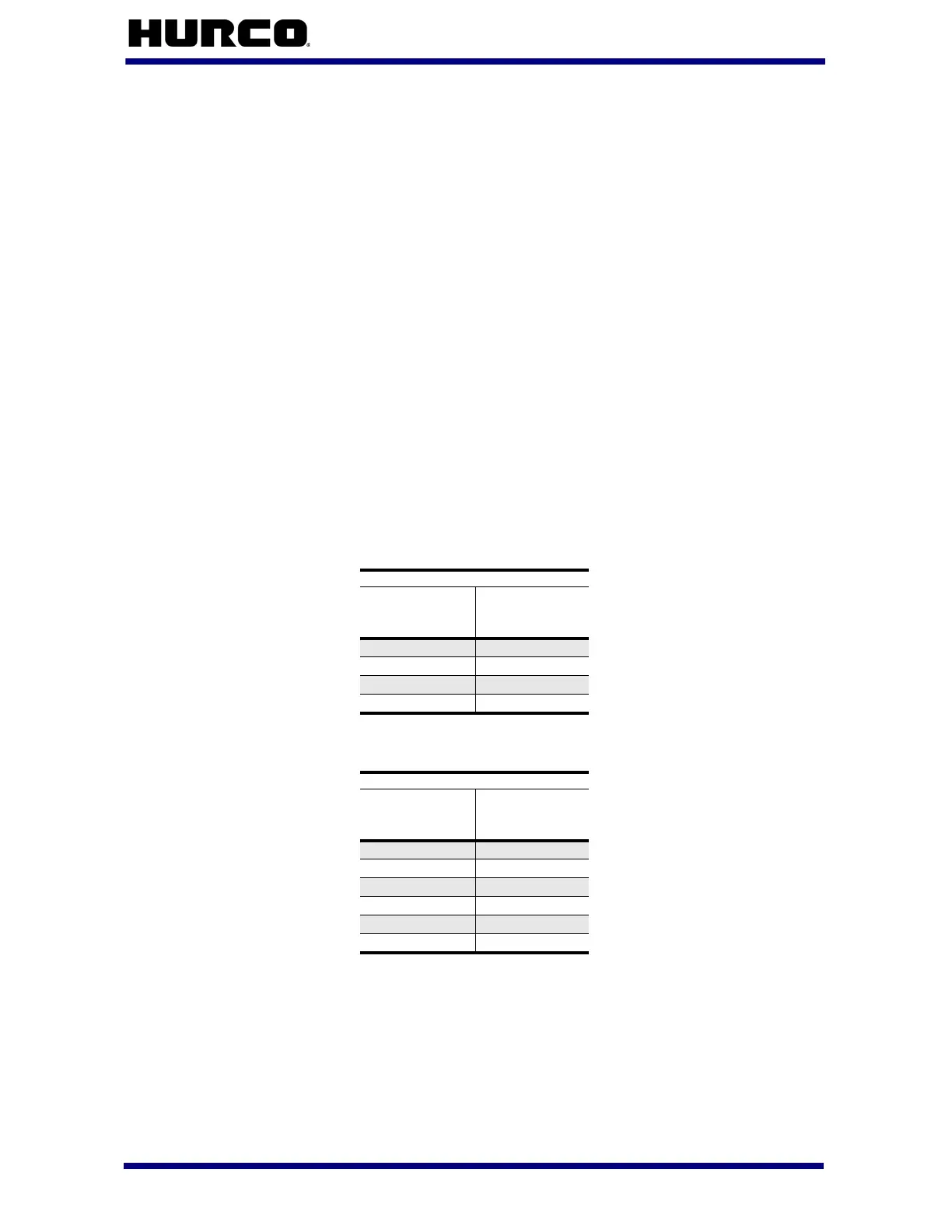

Table 3–11. 600 Max RPM Spindle Run-in or Cycle

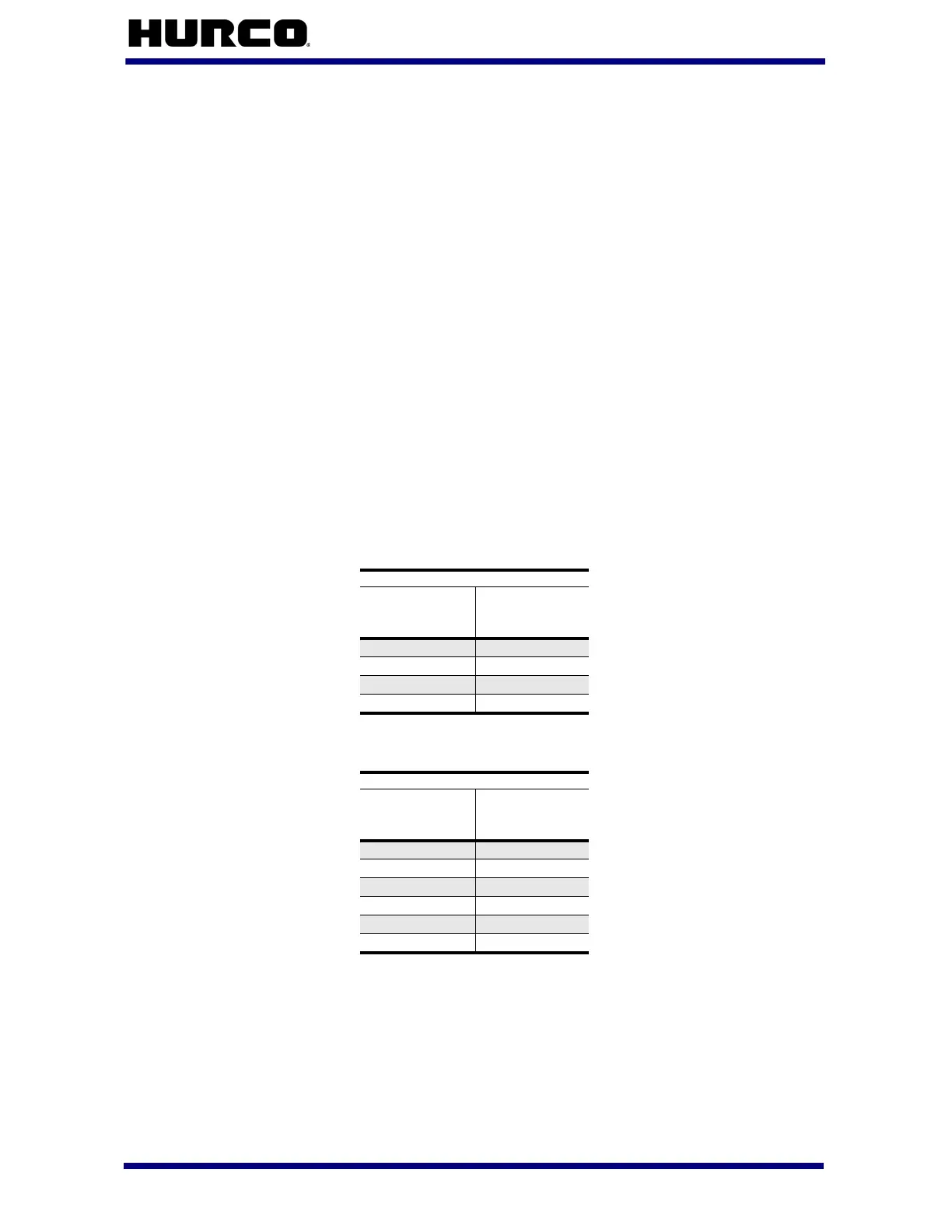

Table 3–12. 8000 Max RPM Spindle Run-in or Cycle

6000 Max RPM Spindle

Run-in or

Cycle Speed

(RPM)

Spindle

Run-in

Run Time

1. 1500

15 min

2. 3000

15 min

3. 4500

30 min

4. 6000

60 min

8000 Max RPM Spindle

Run-in or

Cycle Speed

(RPM)

Spindle

Run-in

Run Time

1. 1500

15 min

2. 3000

15 min

3. 4500

15 min

4. 6000

15 min

5. 7500

30 min

6. 8000

60 min

Loading...

Loading...