6 Interface Between CNC And PLC

6 - 11

When bit C006 = 1, the current execution is in SINGLE mode. Pre CYCST to

execute. If AUTO and SINGLE modes are selected at the same time, the priority of

SINGLE mode is higher than AUTO mode.

While in SINGLE mode, one block of data will be read from the memory for

execution if a cycle start signal is entered. Operation can be changed to MDI or JOG

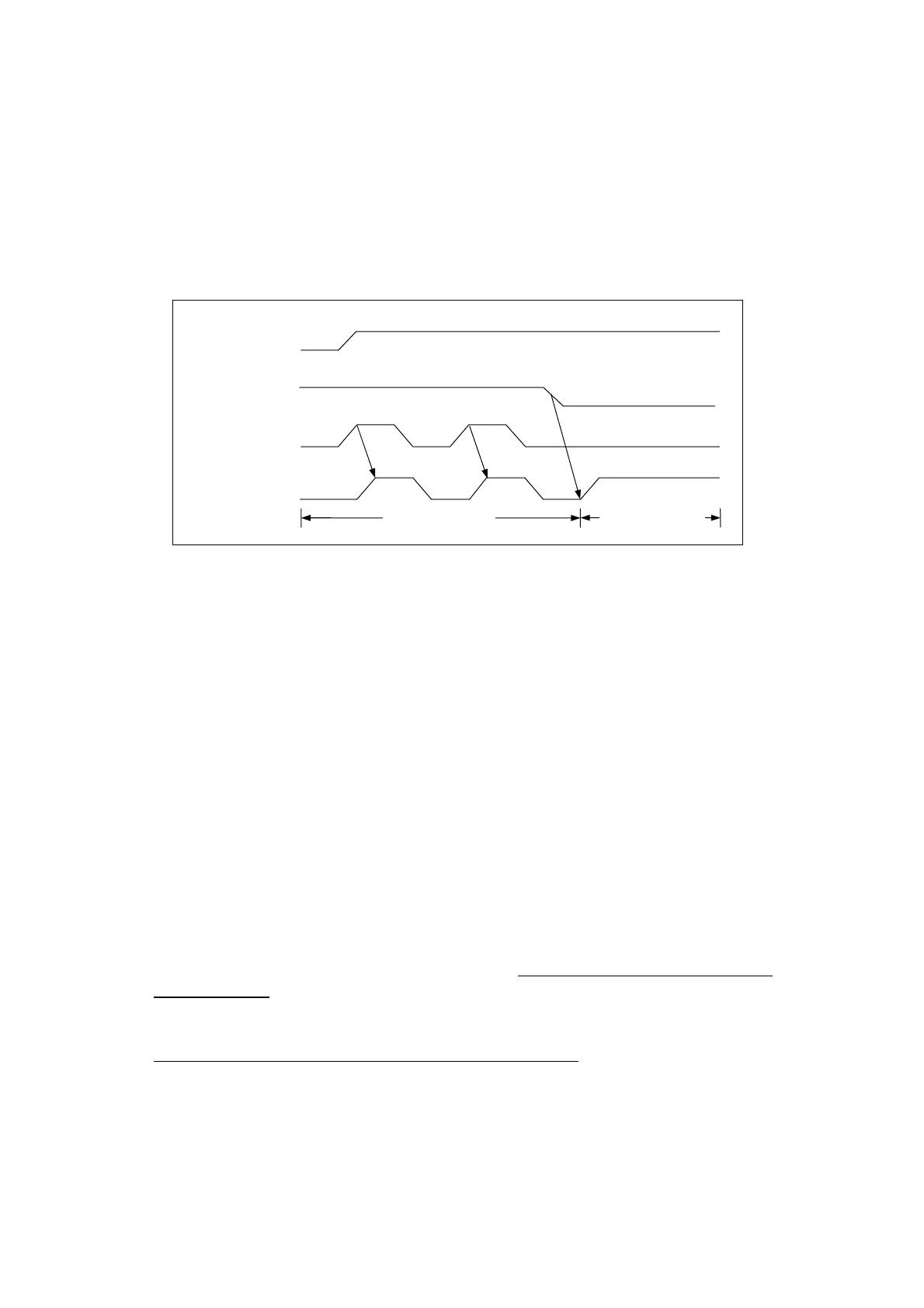

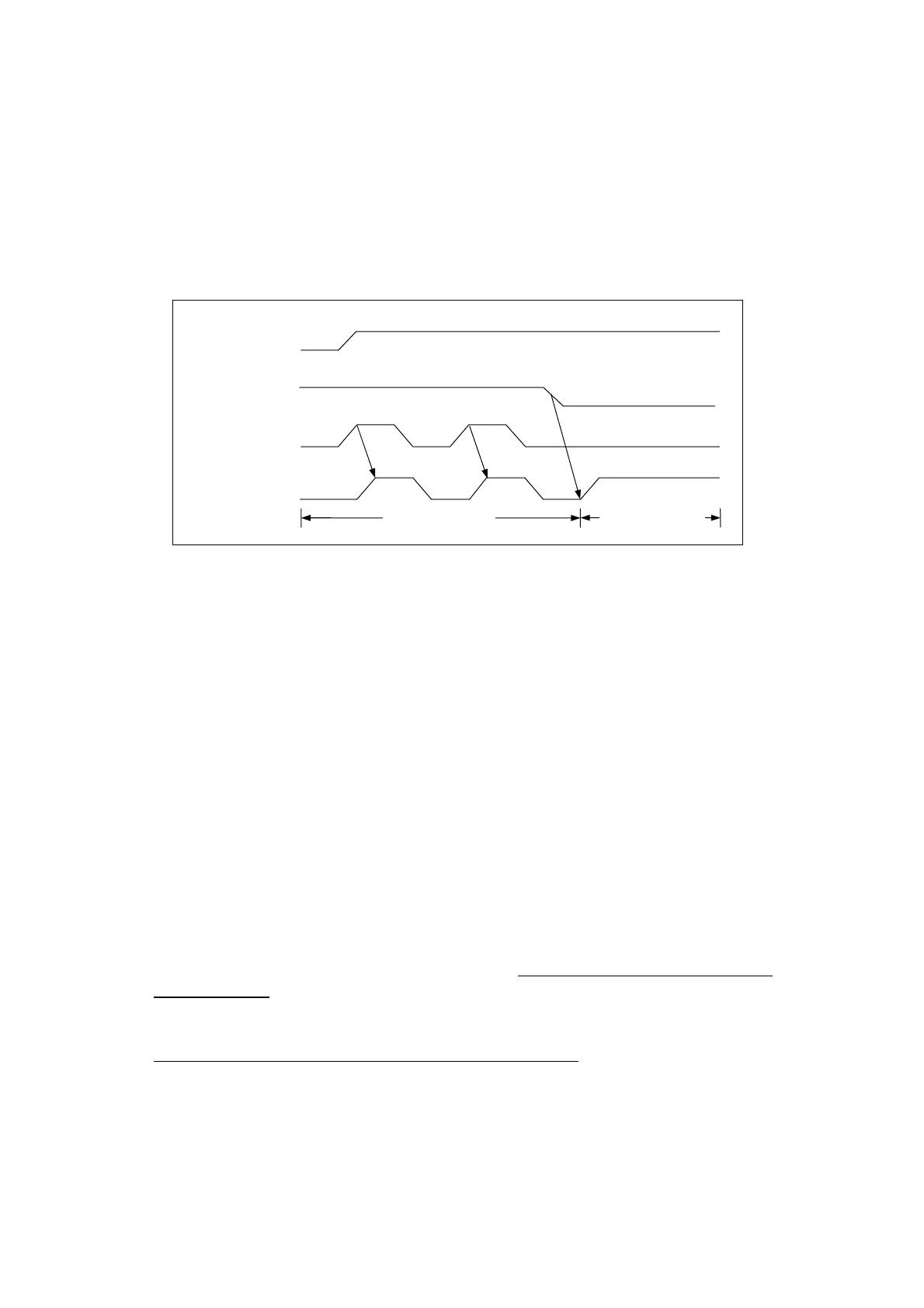

by the mode selection signal under single block state. Fig 6-8 is a time chart for

SINGLE block execution.

Fig 6-3 Time Chart for Single Block Execution

• NC Alarm (C007)

C007 = 1 (high), NC alarm is ON.

C007 = 0 (low), NC alarm is OFF.

Bit C007=1 to inform the CNC unit a machine problem has been detected. When the

external device encounters any trouble, such as spindle servo alarm, these alarm

signals can be used, through input points, to inform the control unit to stop execution

by setting C007 high (1). LCD screen displays ERROR 37 NC ALARM. Resolve the

problem, RESET before restart the program.

• Program Restart-1 (C011)

C011 = 1 (high), Program Restart mode ON.

C011 = 0 (low), Program Restart mode OFF.

If you interrupt the program execution by pressing RESET or Emergence-stop, you

can set C011=1 to restart the execution from the program block where the program

was interrupted. HUST H2N does not provide this function key on the keyboard and

it must be processed through PLC.

Follow the steps below to restart the interrupted program:

1. Press RESET. Use MPG to move tool away. If the interruption was caused by

Em-stop or servo alarm (Error 2), execute HOME then RESET.

2. Press user installed [Restart] key to set C011 = 1 in PLC as follow.

Single Mode

Auto Mode

Continue Execution

BLK2BLK1

off

off

off

on

on

on on

off

Cycle Start

C004

Single Mode

C006

Auto Mode

C006 off

Loading...

Loading...