1 Introduction

1 - 1

1 INTRODUCTION

This manual explains the HUST H2N controller's electrical as well as structural

design necessary for connecting the CNC to the machine tool. It also describes the

HUST H2N connection signals including input, output, internal signals, such as S-

bits and C-bits. This manual also describes the functions and the ladder diagram

with corresponding signals. For the functional information of HUST H2N controller,

please refer to the HUST H2N Operation Manual. This manual is intended for users

with some basic electrical and electronic knowledge.

Chapters 1~5 are for those who are interested in electrical connection and Chapters

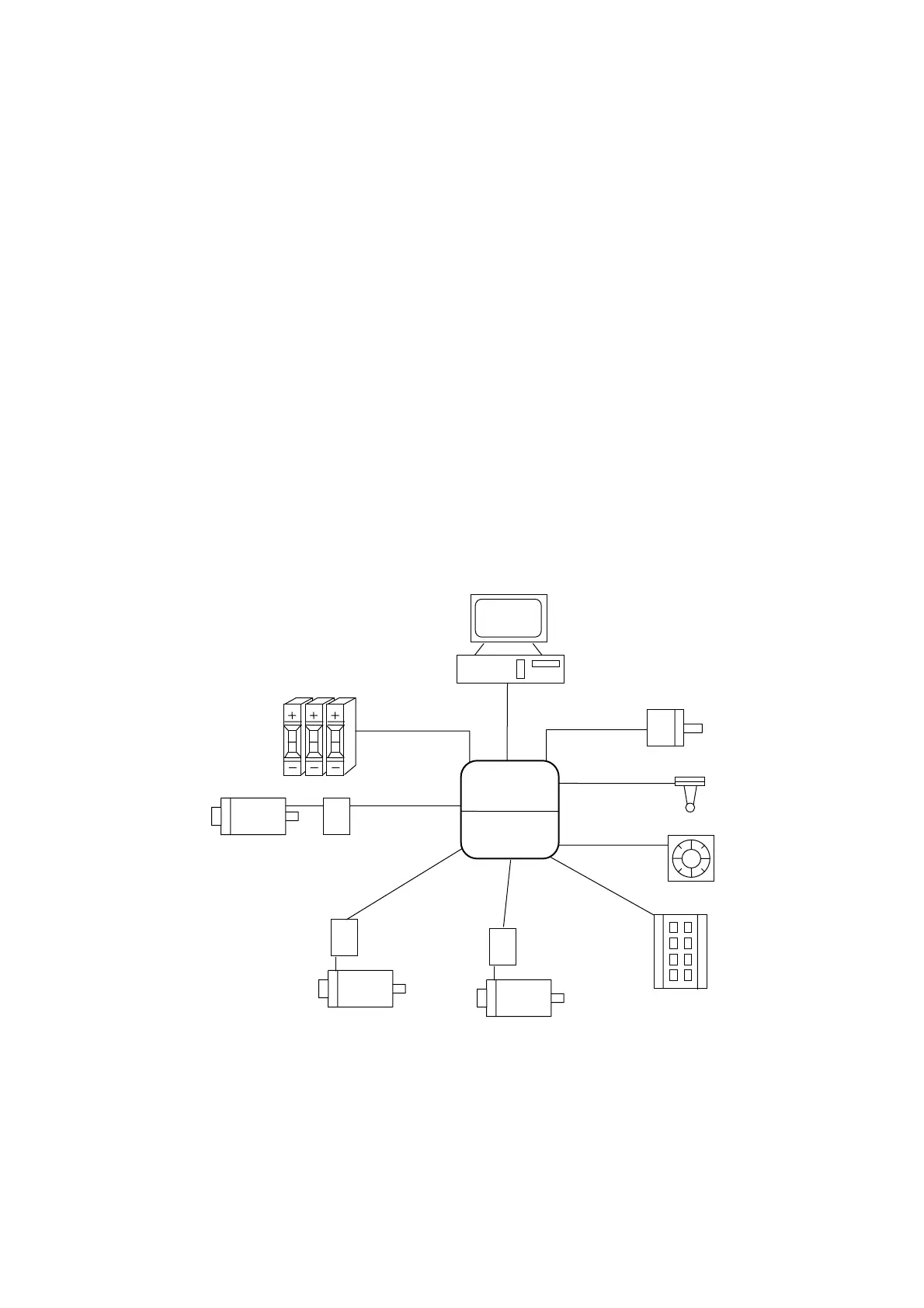

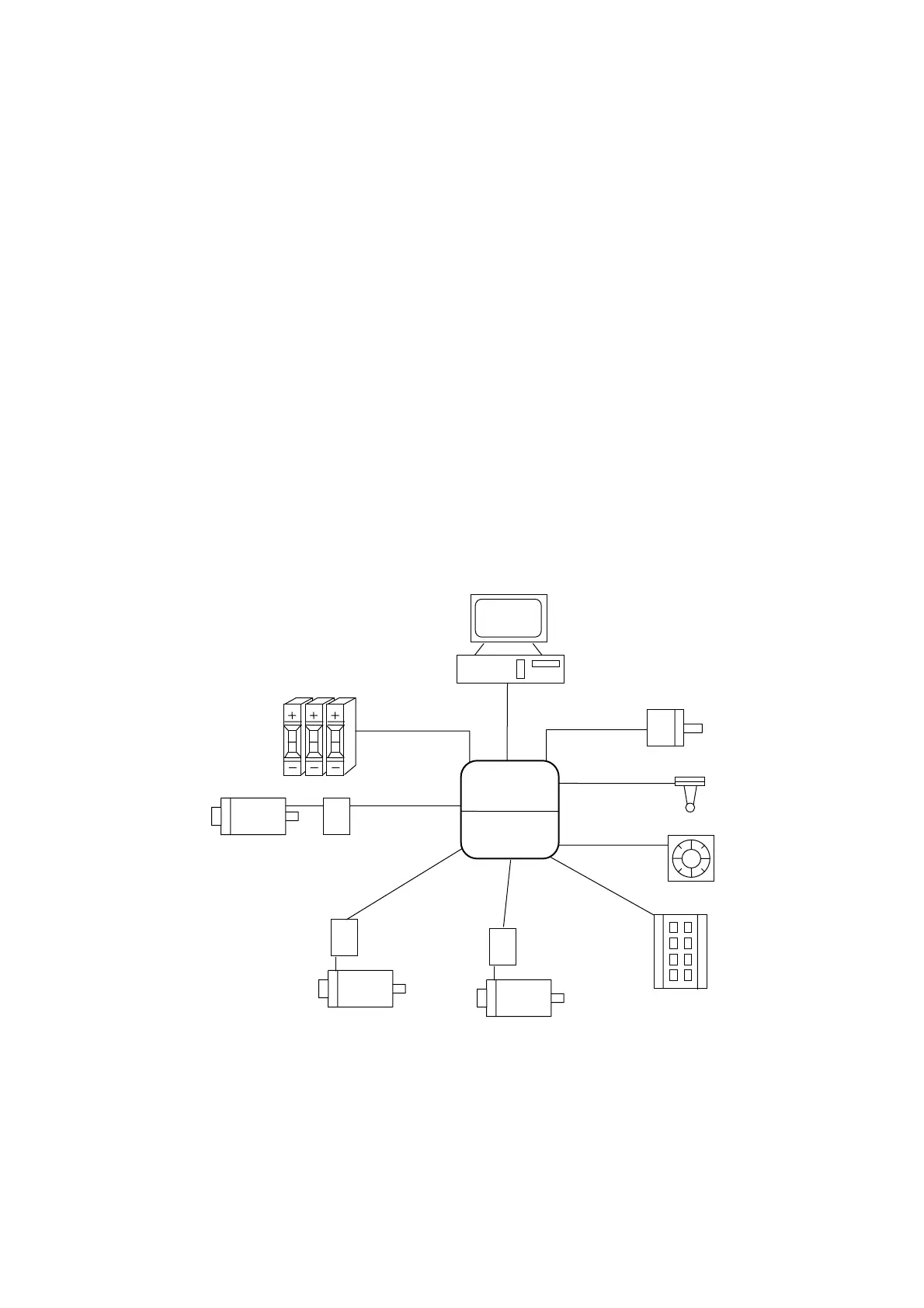

6~8 are for those who are familiar with HUST PLC Editor. Fig 1-1 is a typical

system application of HUST H2N controller to the external devices. The main

features (also see Chap 1 of Operation Manual) of the system are described below.

1. The system can be remotely controlled by PC, HUST CRT screen and PC touch

screen through RS232 interface.

2. The system can handle thumb switch signals through PLC ladder program.

3. The system can control both AC servo and stepping motor.

4. The system provides DI/DO=24/16 points. Also included are connections for

MPG, spindle and Skip sensor.

Fig 1-1 Applications of HUST H2N Controller

PC

Thumb Switch

Spindle Encoder

Skip

1

Driver

AC Servo

1

Driver

AC Servo

Driver

Stepping Motor

MPG

DI/DO

Board

RS232C

HUST H2N

2 Axis CNC

Internal PLC

(ROM/RAM)

Loading...

Loading...