6 Interface Between CNC And PLC

6 - 13

2. Jump to the 2

nd

program or do some other task such as JOG function.

3. Under AUTO mode, select the program number of the interrupted program.

4. Set C013=1 to read the stored block number in step 1.

5. Set C011=1.

6. Press CYCST.

• Dry-run (C015)

C015 = 1 (high), Dry-run mode selected.

When C015=1, the control unit will execute Dryrun function. The dryrun mode can

be set at any time during program execution. When dryrun is set, the feed-rate will

change to fast speed at the beginning of next block. When dryrun mode is turned

OFF, the feed-rate will return to normal cutting speed at the beginning of next block.

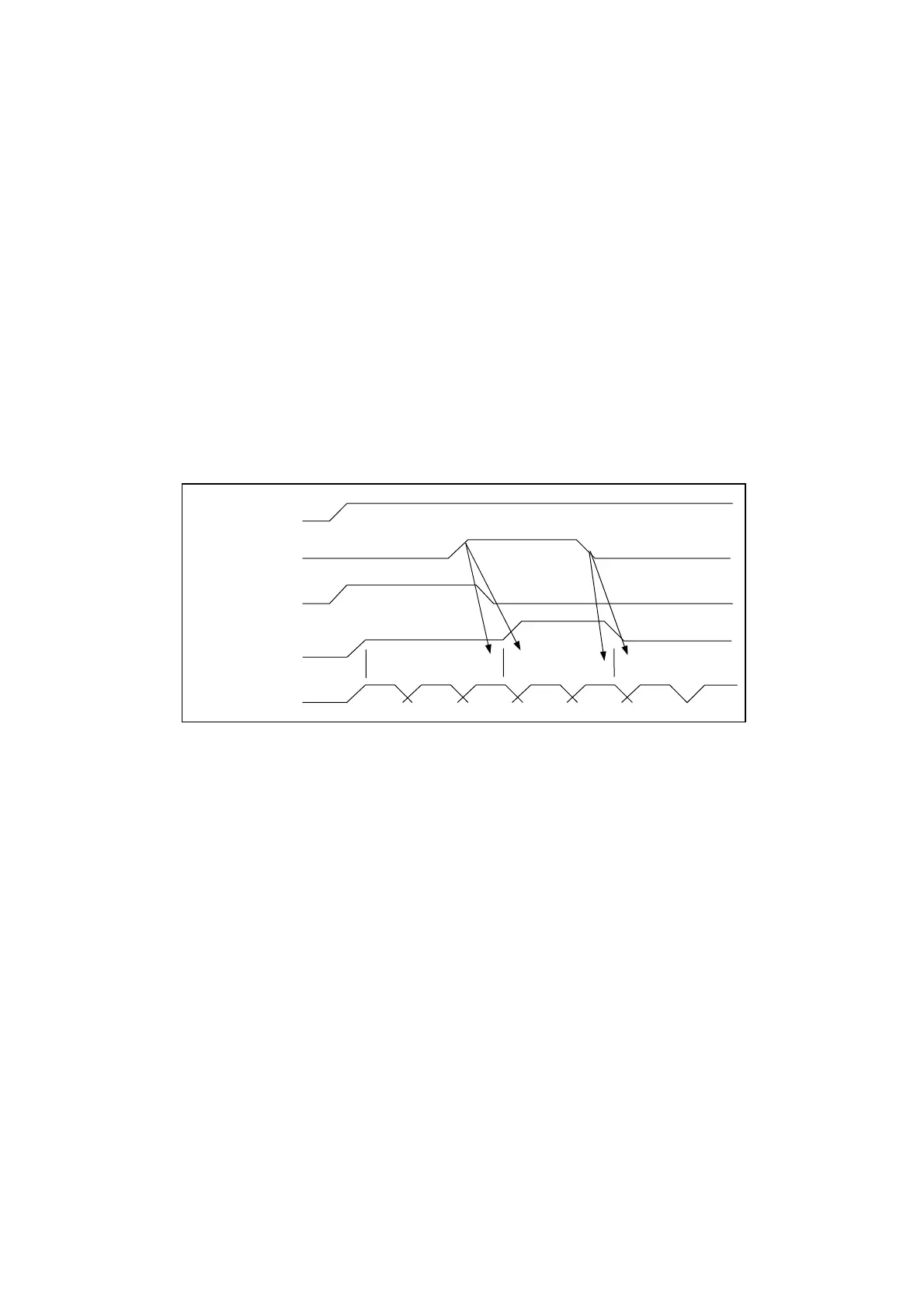

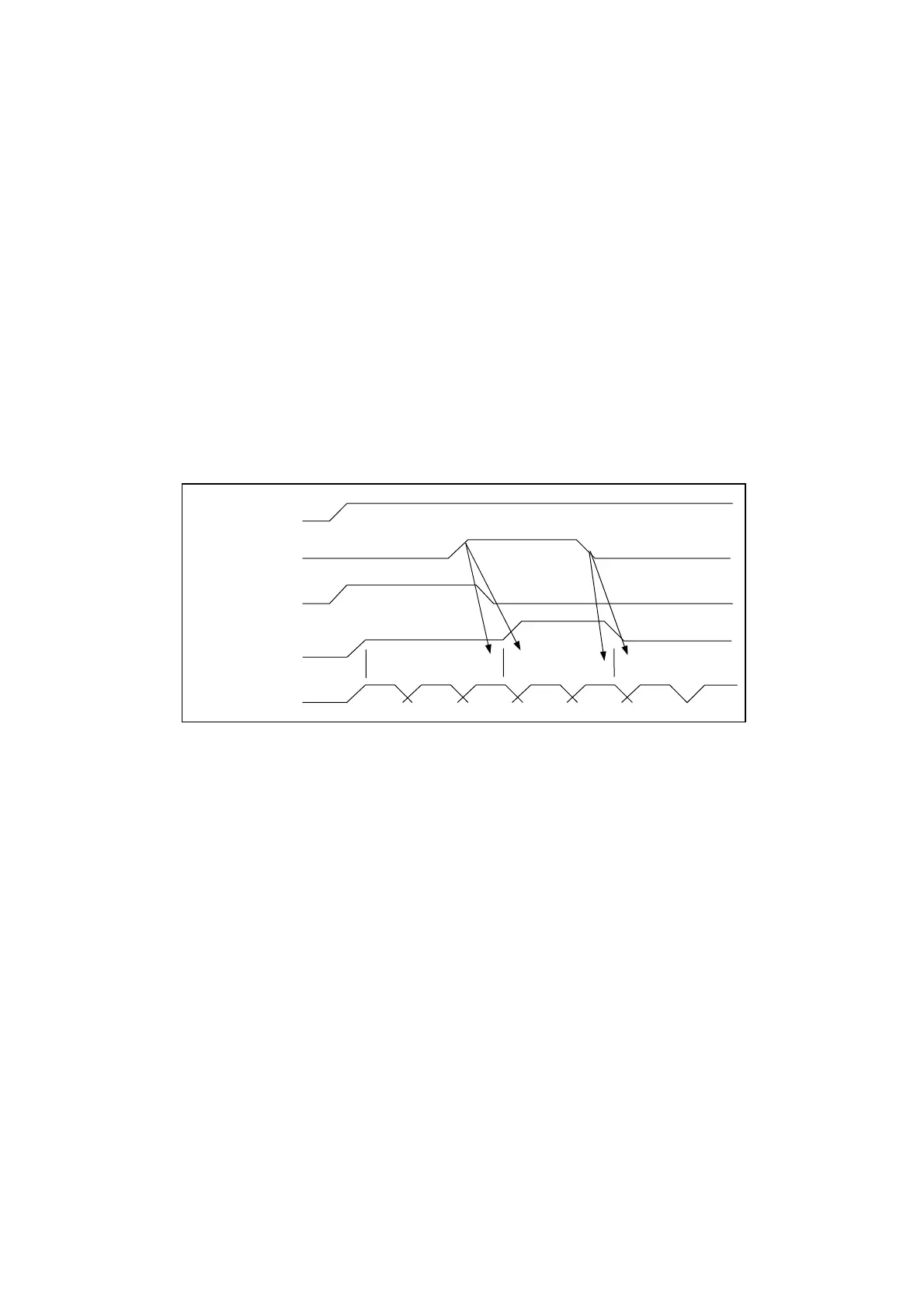

Fig 6-5 shows the relationship between dryrun mode and normal execution mode.

Notice that G00 manual feed-rate override is also effective.

Fig 6-5 Time Chart for Dryrun During Program Execution

• Cursor Up And Cursor Down (C020~C021)

C020 = 0 ~ 1 (rising edge), the cursor moves up one line.

C021 = 0 ~ 1 (rising edge), the cursor moves down one line.

Bit C020 informs the control unit to move the cursor one line up. It is effective only

at the moment when the signal (C020) rises from low (0) to high (1). This function

can be controlled by external input to remotely move the cursor. Bit C021 is for

Cursor Down function.

• Page Up And Page Down Key (C022~C023)

C022 = 0 ~ 1 (rising edge), move cursor one page up

C023 = 0 ~ 1 (rising edge), move cursor one page down

Bit C022 informs the control unit that Page-up function has been selected. When bit

C022 is rising from low (0) to high (1), move cursor one page up. This function can

be controlled by external input. Bit C023 is for Page-down function.

1

2 3 4 5 6

7

Off

Off Off

Off

Off

On

On

On

Auto Mode

Dryrun C015

Cycle Star

Feed Rate

Cutting speed Dryrun speed

Block Execution

Cutting Speed

Loading...

Loading...